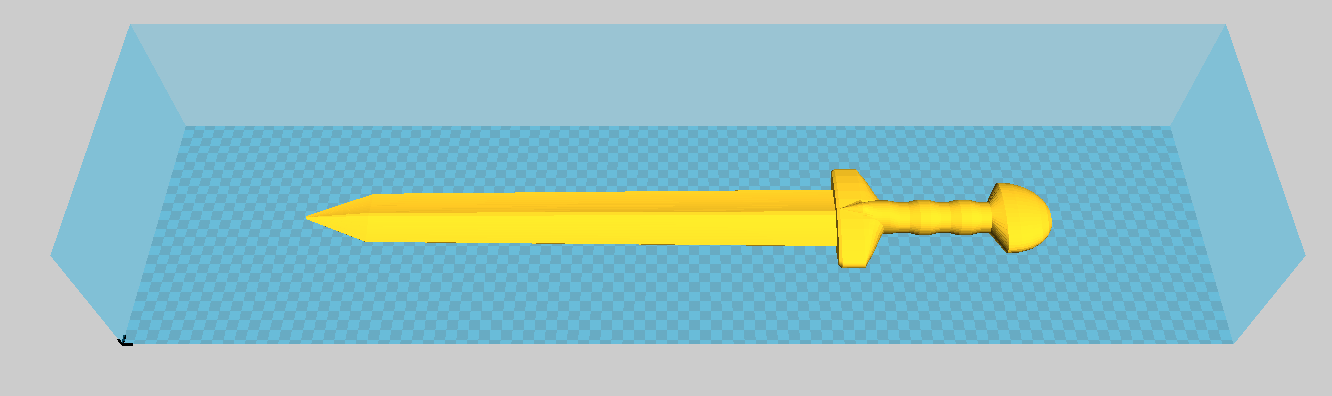

20cm X axis, 30 cm Z axis, 100 cm Y axis. or switch the X and Y axis, it doesn't really matter. Need some visualization for that?

That's a Pompeii gladius, full scale, printed on this bot. Yes, it's big.

The design

I've chosen to base this printer off the D-bot Core XY printer. As far as I can tell, it's the best design for printers with one very long axis; the only thing being thrown around the long axis is the print head carriage. This decreases the inertia and will produce better prints. Also, the torque from both the X and Y motors will be used at all times. This will work, and it might work well enough to get rid of the bowden cable.

There will be a few changes to the design. I'm getting rid of the cantilevered bed design and putting four steppers on the Z axis. I'll be using an aluminum (mic6) build plate. That's heavy, and I'll need the extra support and torque from the motors. The Z motors will not be independant. Instead, I'm using this shitty breakout I designed.

A Heated Bed

For large 3D printers, the heated bed is the largest problem. A 200mm x 200mm heated bed draws about 80 Watts, or about 5 W/cm^2. The same power density for this printer looks like this:

Yeah, 43 Amps of 230 mains to get the same power density as the standard RepRap heated bed. This is the problem with large 3D printers.

I can do a heated bed with ~1W/cm^2, which brings the power requirement down to something sensible. For now, though, I'll just print in PLA while making provisions to get a silicone heated bed and a 230V outlet installed.

I've begun printing the parts for the D-bot, and since enlarging it is basically only a matter of ordering more extrusion, there aren't many modifications necessary. Once the parts are printed, I'll spend the $150 on extrusion, $250 on hardware, and get assembling. The print bed is the biggest challenge, but the Hackaday design lab has a shopbot.

Benchoff

Benchoff

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Has anyone ever tried selective heating? It seems like a waste heating the whole build area, your sword probably only uses 10% of the build area and if it was the only area heated it wouldn't require so much power. The issue with this is probably stressing the glass by having temperature gradients in it. Might not be a big deal or it might just shatter one day because you chose a shape that stressed the glass in a weird way.

Are you sure? yes | no

Hi there, 80 W on 20x20cm is actually 0,2 W/cm^2. 80W is quite weak and probably won't reach temperature. I'd say the bare minimum on 20x20cm is 120W if you want to reach 110 °C. In general, 1 W per cm^2 is a really, really good output for 3D printing and 0,5 W is still ok.

You can puzzle together a 30x120 cm heated bed from 10 pcs of 60x6cm PCB which will cost you about $120 including shipping at DirtyPCBs. Why puzzling? Because 60cm is the max. size there and 10 pcs the MOQ. If you want to run it from a single 230 V phase, just layout the resistance for 0,5 W / cm^2 and you'll be fine. For three phases I'd use 1W/cm^2. Hmm, three phases.

Are you sure? yes | no