While I am waiting for the drill-bits to arrive I thought I might point out a few points of caution to be observant of on this project, as well as a few general case observations as regards Electrical Design (at least as far as production).

First, this is, basically, a 'commodity' phone, sourced and made in China, likely transported by truck, boat, crossing oceans, and in turn, a vast logistics system such that, at least presumably, every party makes some profit on what ultimately is a $20 Walmart item.

I remember reading a few months ago a related tale from a third party related by Scott Rider, as part of his 'Mostly True Tales' segment on the Adafruit blog (found here in Part 1 and Part 2). The gist of the story being the experiences of an Engineer at Blackberry, and an example of on a 'high-volume' item (in this case ~3.5 million units a year), even the potential single part price difference on the order of fractions of a cent ($.01123) between parts can, potentially, result in many hundreds of thousands of dollars of cost savings over the long run.

The story is interesting both for that point, and for the way, well, things actually turned out (i.e. politics).

But I think part of the take home is the fact that whenever possible on a low margin, high volume item, corners will sometimes ruthlessly be cut.

Granted, also, these days, at least in the West, for a desktop phone (as opposed to say a cell phone), who goes to have it fixed/repaired anymore ?

So granted, the design here was never really intended to be opened or tinkered with, and if left on its own, likely would function just fine with no problems.

However, if one has to hack, change, reverse engineer one suddenly has to be aware of some of these design issues.

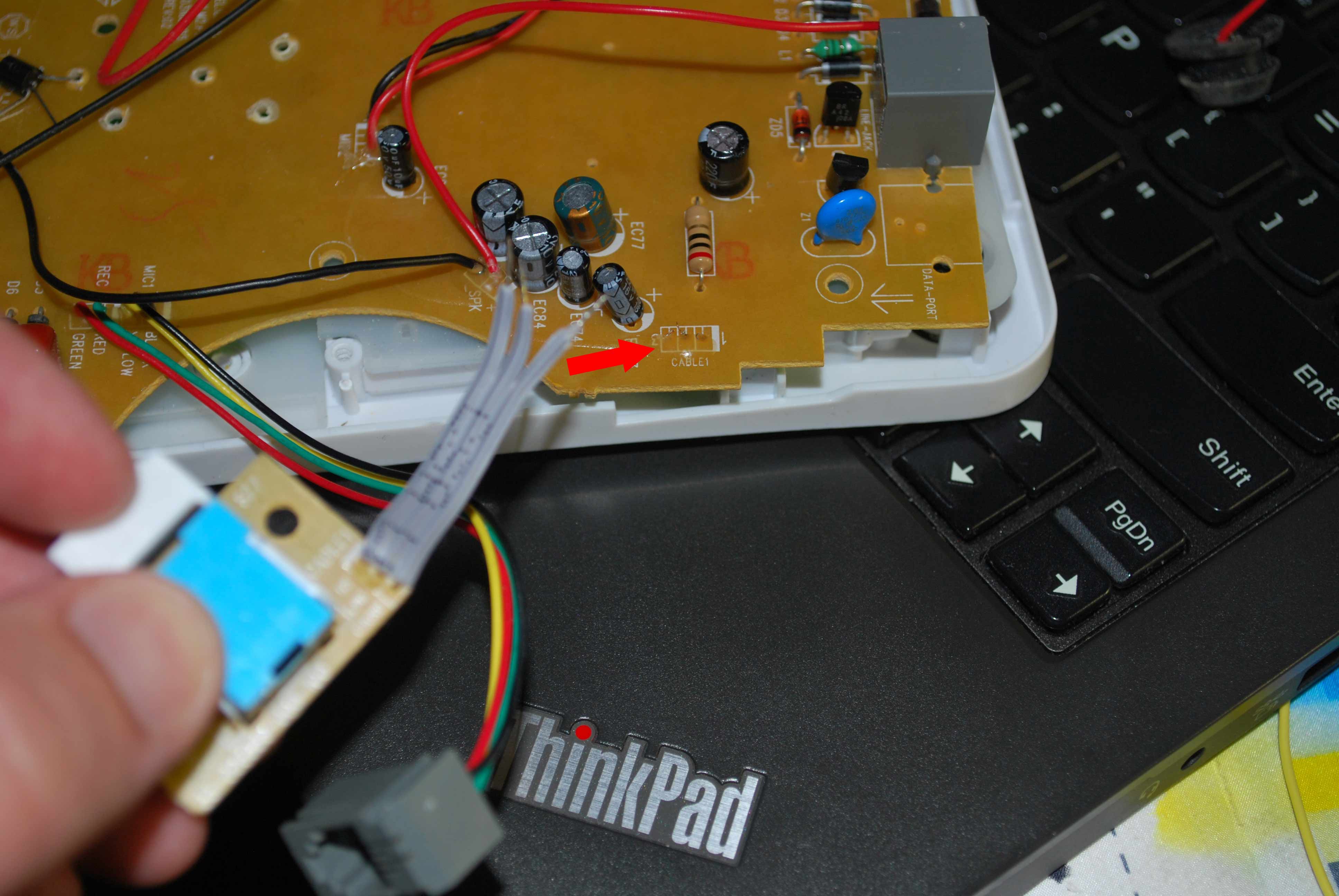

Point in case here relates to the structures of the bus lines within the phone. Below is the cable (or was the cable) for the rocker switch (or the button that determines whether the phone is on the hook or not).

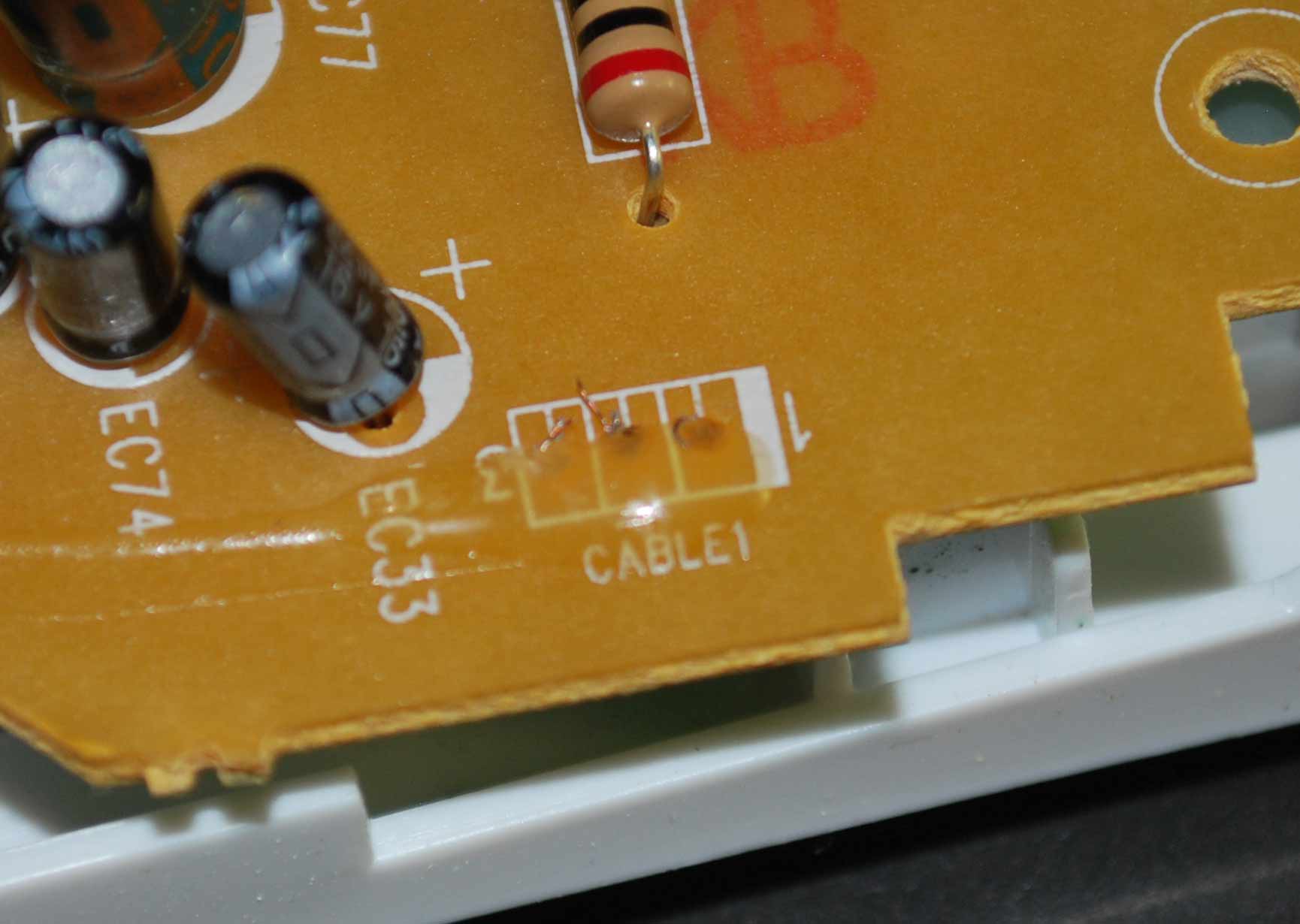

The red arrow points to where it was connected. And very honestly, this came off very, very early on in the build, before the drilling stage, not because it became caught, or was pulled, it just 'moved' or bent a few times and kind of snapped right off.

Now on a more expensive item one might expect to see connectors here on either end, but again this is low cost.

Further, there is evidence that from production that they new the solder joints were not very strong as one can see the cable was further affixed with hot glue:

After removing the surface glue and sucking out the solder from the opposite side, I was able to reattach this connection with no wields between the contact points and a much stronger joint connection-- it can be pulled on now and has been tested working.

However, one might say, well, its only a three wire connection, not too much of a big deal...

Yet the much larger bus connection to the screen is rigged up in just the same way, and would take much, much longer to have to rework.

In any case, something to point out and a word of caution.

Anthony

Anthony

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.