Project cpntributing for the "Organization Prize"

organization : PFT INNOVALTECH (France)

files can be downloaded on this project page, or here :

https://www.thingiverse.com/thing:2796285

1 - Introduction

Sustainable development is becoming ever more present in the collective spirit, which is a good thing. The consumption of local products and the reduction in our consumption of products are two pillars of this long run lifestyle.

In this spirit, the repairing of our everyday objects is a very good thing; and what's more local than tasting homemade cakes!

Ahh, homemade cakes ... without preservatives, always original, and so cheap!

2 - The part to be replaced

Unfortunately, a part of my wife's food processor broke ... So this is an opportunity to prove that 3D printing combined with some mechanical knowledge fits perfectly in a context of "sustainable development".

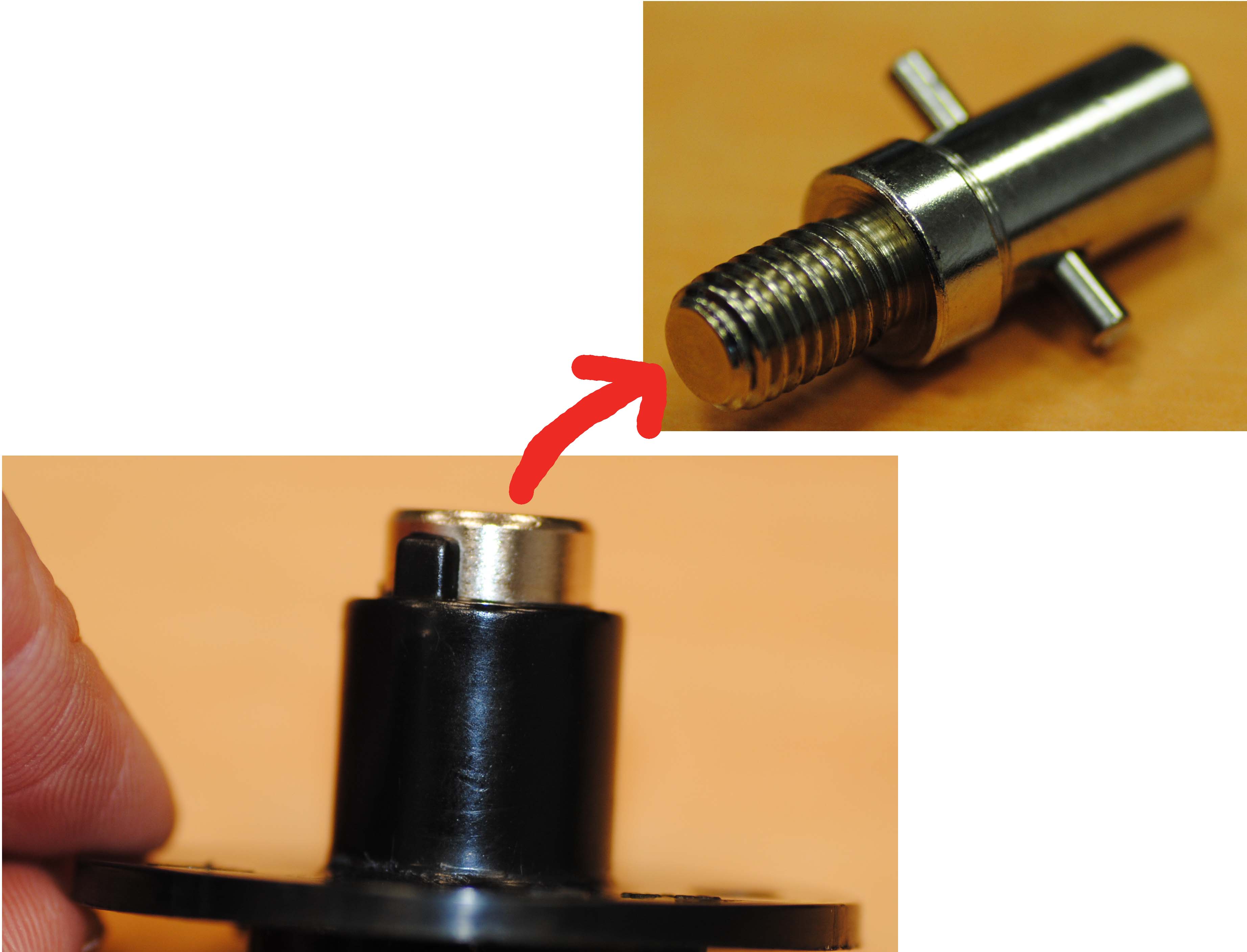

Here is the part : let's call it "protective cone" :

3 - Breakdown analysis

After dismantling, we understand quickly how this case occurred.

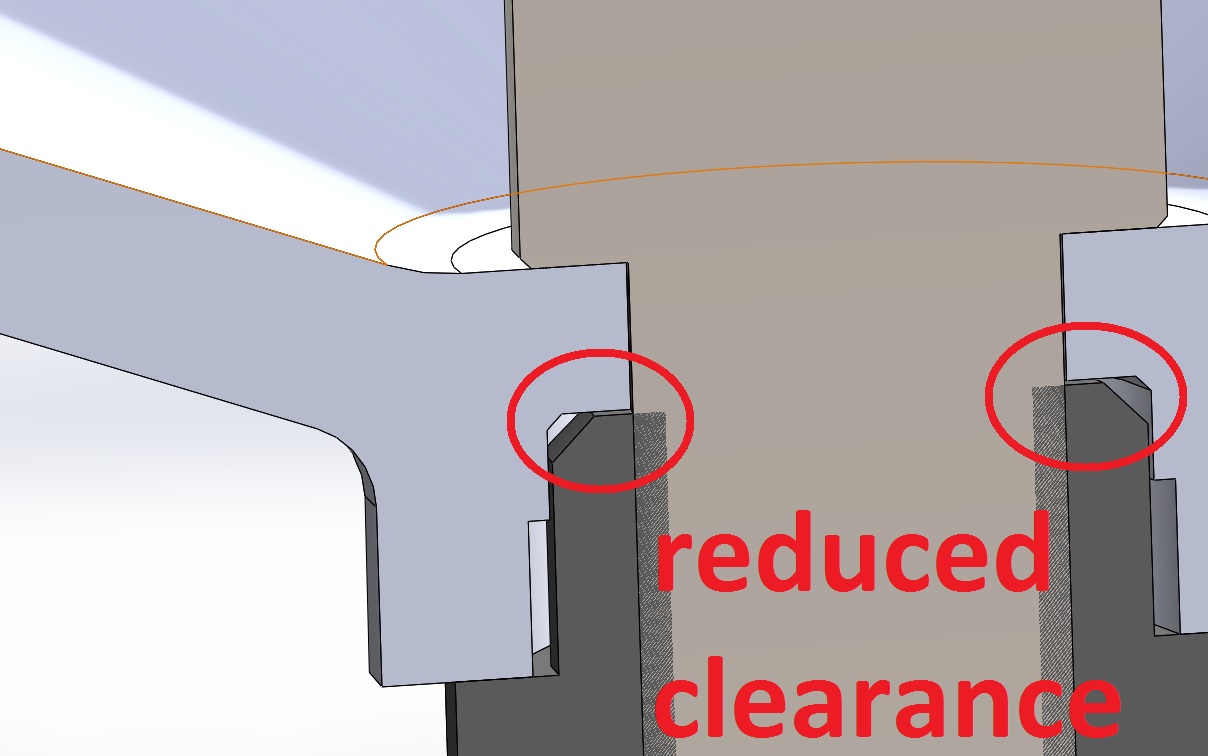

As can be seen in picture below, there is a large clearance between the two metal parts screwed into one another.

When the motor drives the axis in rotation, it tightens the threaded part, and crushes more the "protective cone", which is deformed in the space left by this too important clearance. From the uses, the rupture of the part took place; this closely resembles a fatigue failure.

4 - Design of the replacement part

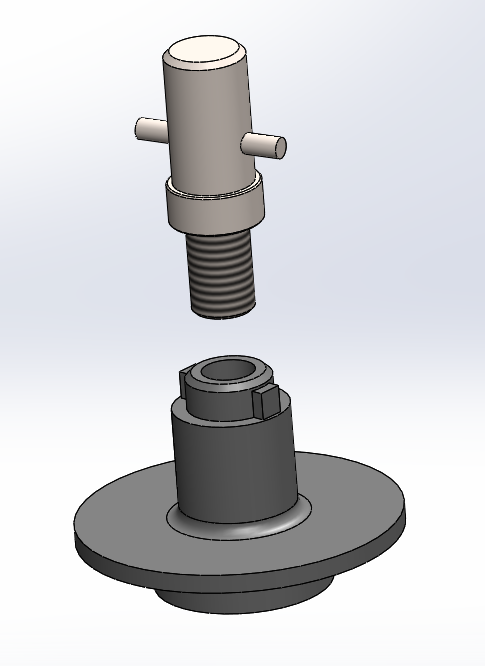

Before redesigning the replacement part, a small reverse engineering work was required. After taking some measurements with a caliper and a bit of designing with a CAD software, here are the parts around which it will be necessary to work :

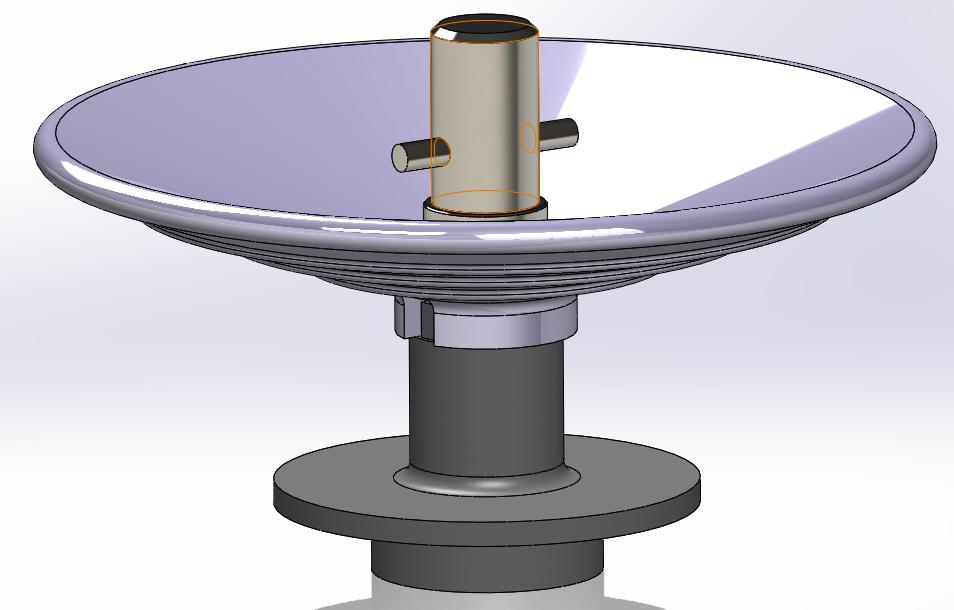

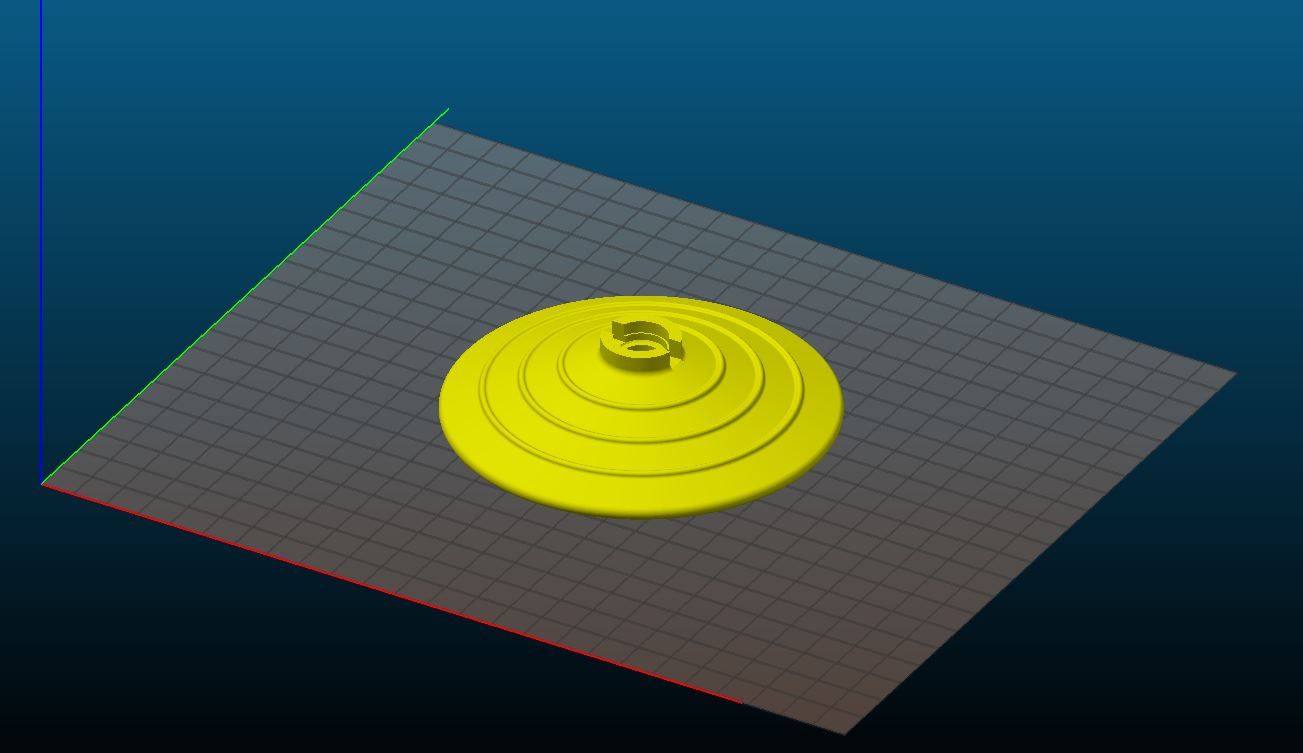

And here is the replacement part drawn in its context:

The functional clearance to achieve a "state-of-the-art" assembly has been preserved, but considerably reduced in order to avoid the unnecessary solicitation of the "protective cone".

5 - Part printing

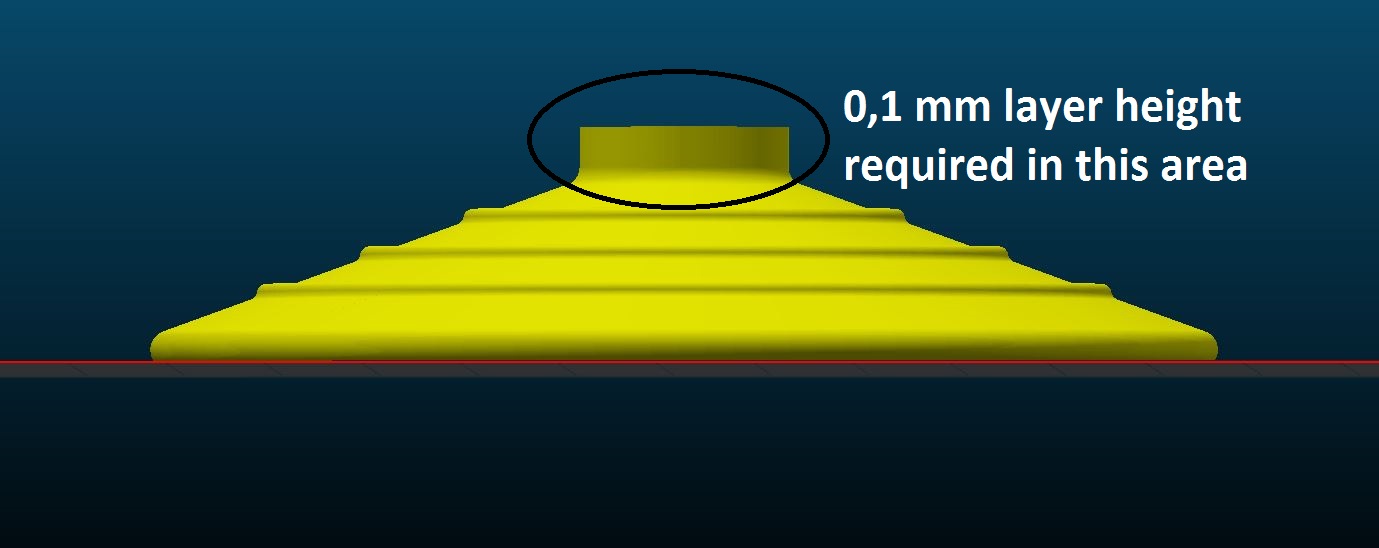

The part area with the slot is the one that requires the most precision. Thus, this area has been placed facing up on the printer bed (we must never forget that in FDM 3D printing, the first layer is never really accurate [0.2mm deviations are frequent depending on the machine], and in our case , the expected functional clearance is 0.15 mm ...).

The piece was made of PLA, which I think is compatible for parts in contact with food (I bought my daughter a mug made in injected PLA).

The layer height for the conical shape of the part is not that important ; this may vary according to your aesthetic tastes, and if you wish to polish the piece once finished (the smaller, the easier).

I recommend, to respect this clearance of 0,15 mm to use a layer height of 0,1 mm for the cylindrical area of the part. (Most slicers allow today to use a "variable layer height", it is an opportunity to use this function)

Finally, because of the shape of the piece, I recommend using support.

Below, are some other parameters that may differ from the default settings (I use Slic3r):

-

5 perimeters for vertical shells

-

40% cubic infill

6 - post-processing

Once the support removed, it is possible to polish the part, to facilitate its cleaning in use, even if it is not mandatory (polishing, not cleaning !). The paint, or any other type of epoxy coating is to be avoided, to not contaminate the food!

7 - mounting, and let's cook !

The assembly is extremely simple: the threaded part is put back in place. that's all !

The whole family is happy again !

8 - Conclusion

This example of "repair you can print" is perhaps not very spectacular, or outstanding... BUT, this fix illustrates how 3D printing can incorporate the everyday life. The arrival of 3D printers in homes, in addition to becoming almost indispensable in the makers and hackers workshops, allows, and will inculcate massively a technical culture to all, and give a second or even a third life to many objects.

Many thanks to the editors, and to the community of Hackaday for acting as a catalyst for this positive movement.

Keep the good work !

Matthieu MOREL

Matthieu MOREL