No matter if you are a hardware engineer or an electronics hobbyist, making printed circuit boards is a TIME CONSUMING AND COSTLY routine. You typically need to submit designs to a PCB foundry, spend tens to hundreds of dollars and wait for a week or two to have your circuits made. Often, the first version does not work and iterations are generally needed to perfect the design. This means that you need to spend a lot more time and money! Sounds frustrating, right? That is exactly what motivated us to develop LITHO!

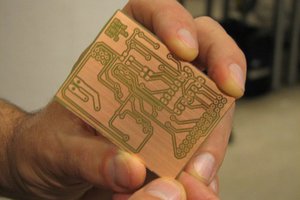

Litho helps engineers and hobbyists test their ideas faster and cheaper than ever! A circuit board up to 4" x 4" can be made within 20 minutes and costs just $2-3 dollars, when and where you want it. Additionally, small circuit features can be printed with high resolution. Smallest feature and pitch separation can be as little as just 8 and 24 mils, respectively!

In addition to printed circuit boards, various patterns can be transferred onto different substrates, such as metals, plastics, granite, and ceramics etc., for arts and jewel making.

Printing circuits and transferring patterns with Litho is as easy as 1-2-3! One just needs to click a few buttons, and the process is fully automatic.

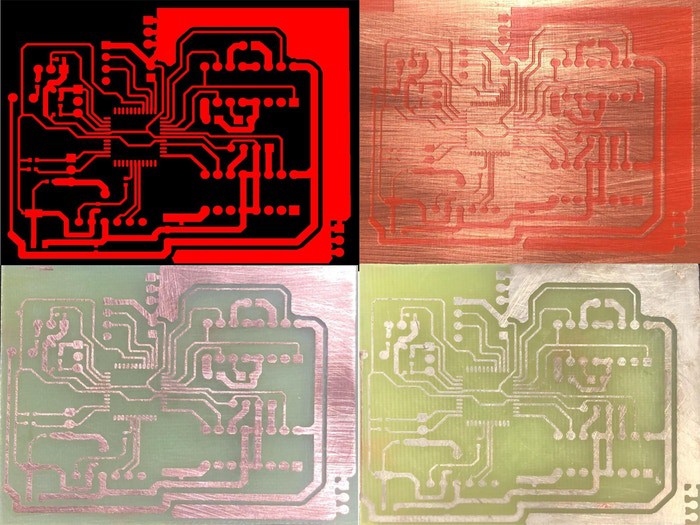

A major component of Litho printer is a novel, wide- spectrum sensitive ink, which allows quick and precise transfer of circuit patterns. When a circuit is projected onto an ink- coated FR-4 board with copper cladding, the ink hardens through photo- polymerization reactions. While the un-cured (i.e. unexposed) ink can be rinsed away using tap water, the hardened ink behaves as an etching mask. Such a mask protects the circuit while copper in the unprotected area is removed when the printed board is subjected to a PCB etchant. Consequently, a PCB can be obtained by easily scratching the thin mask layer using a relatively fine sandpaper. An optional step of tinning can be used to protect the copper and allow easy soldering.

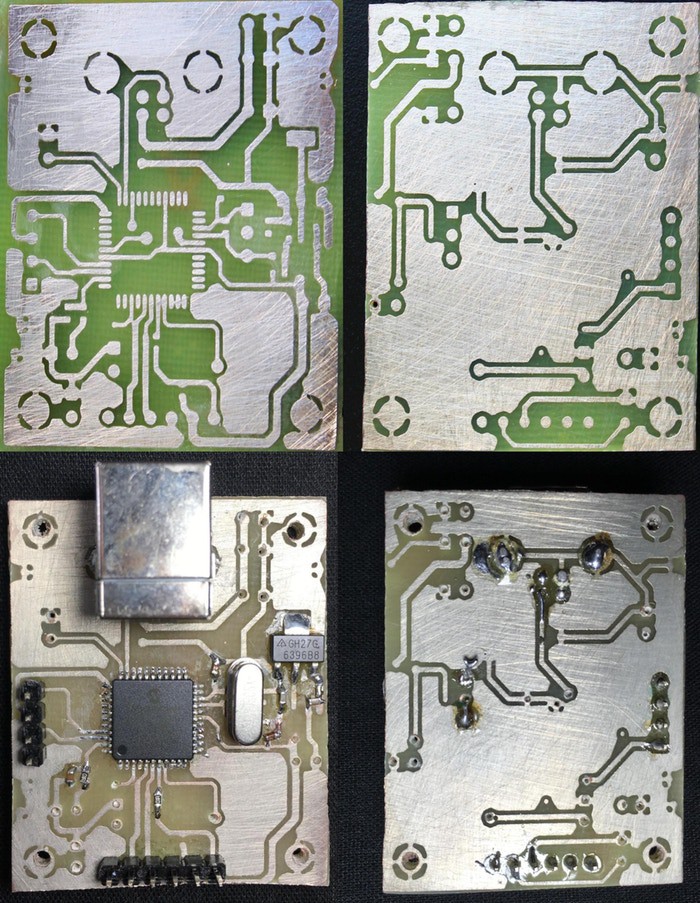

Making a two- layer PCB? No problem! One just needs to sequentially print out the top and bottom layer, stack them up, drill holes and solder interconnecting pins at the desired locations.

With Litho, numerous fully functional PCBs have been fabricated to control LEDs, motors, fans and collect data from sensors. More complex circuits have also been successfully made. For example, we have used Litho to fabricate the electrical vehicle service equipment (EVSE) and successfully charged a Chevy Volt electric vehicle. Additionally, the circuit board controlling the whole Litho printer system can be made with the machine itself! If it works for us, it should work for you as well!

Similarly, the process can be used to transfer patterns for arts and crafts. For example, the same copper- cladded FR-4 plates for PCBs can be used as substrates to form arts with amazing contrasts and details. Additionally, pigments with different colors can be added into clear printing ink to print pictures and drawings on various different substrates, such as plastic phone cases, metal plates and granites, etc. Furthermore, those printed patterns may also act as etching masks. Consequently, not only can you print, but also etch patterns in various substrates so that you can create fantastic crafts and jewels, and show off your artistic talents in front of your family, co- workers and friends!

PCB designer

PCB designer

Michael Delaney

Michael Delaney

Kelvin Brammer

Kelvin Brammer

Benchoff

Benchoff