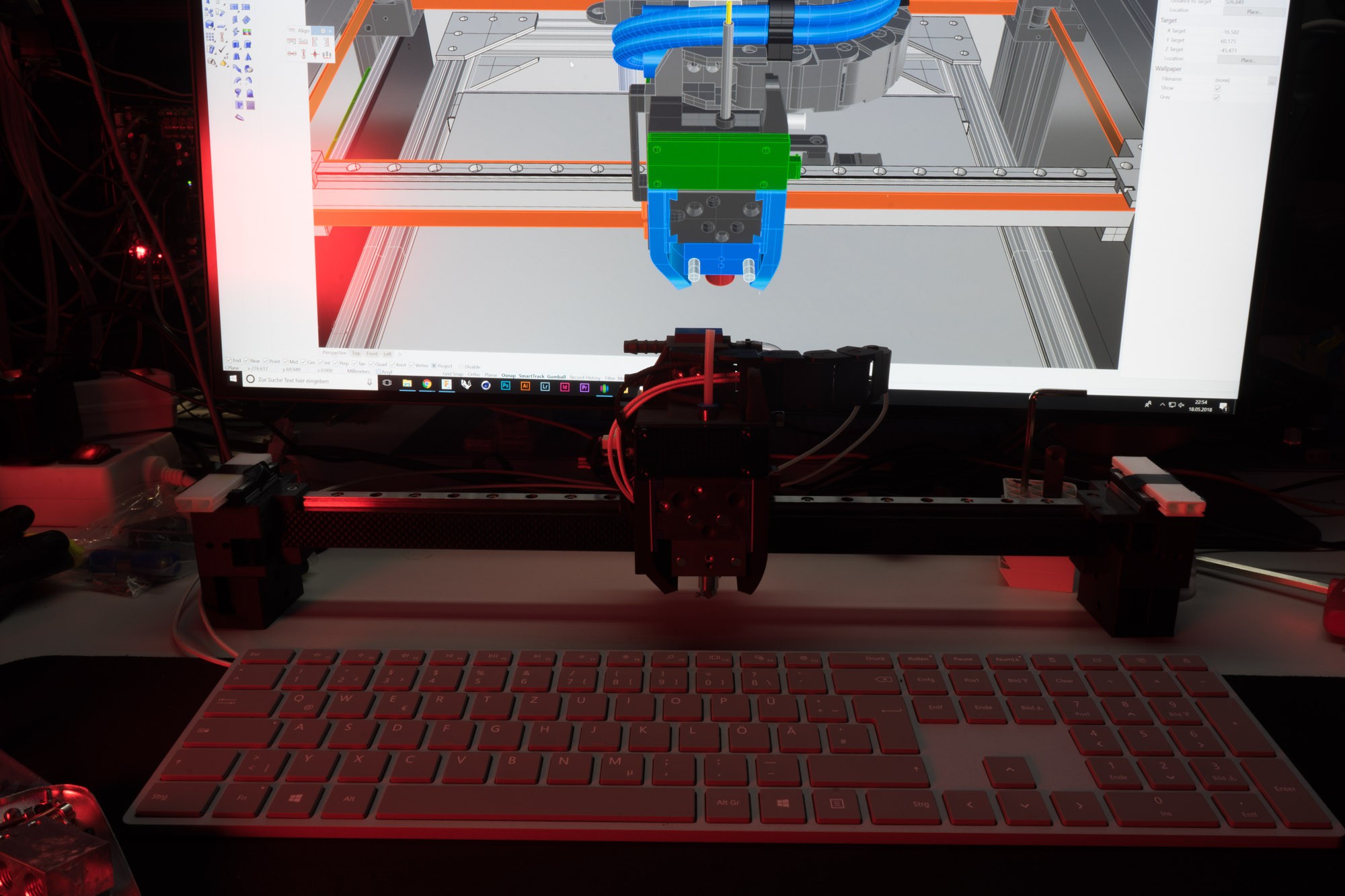

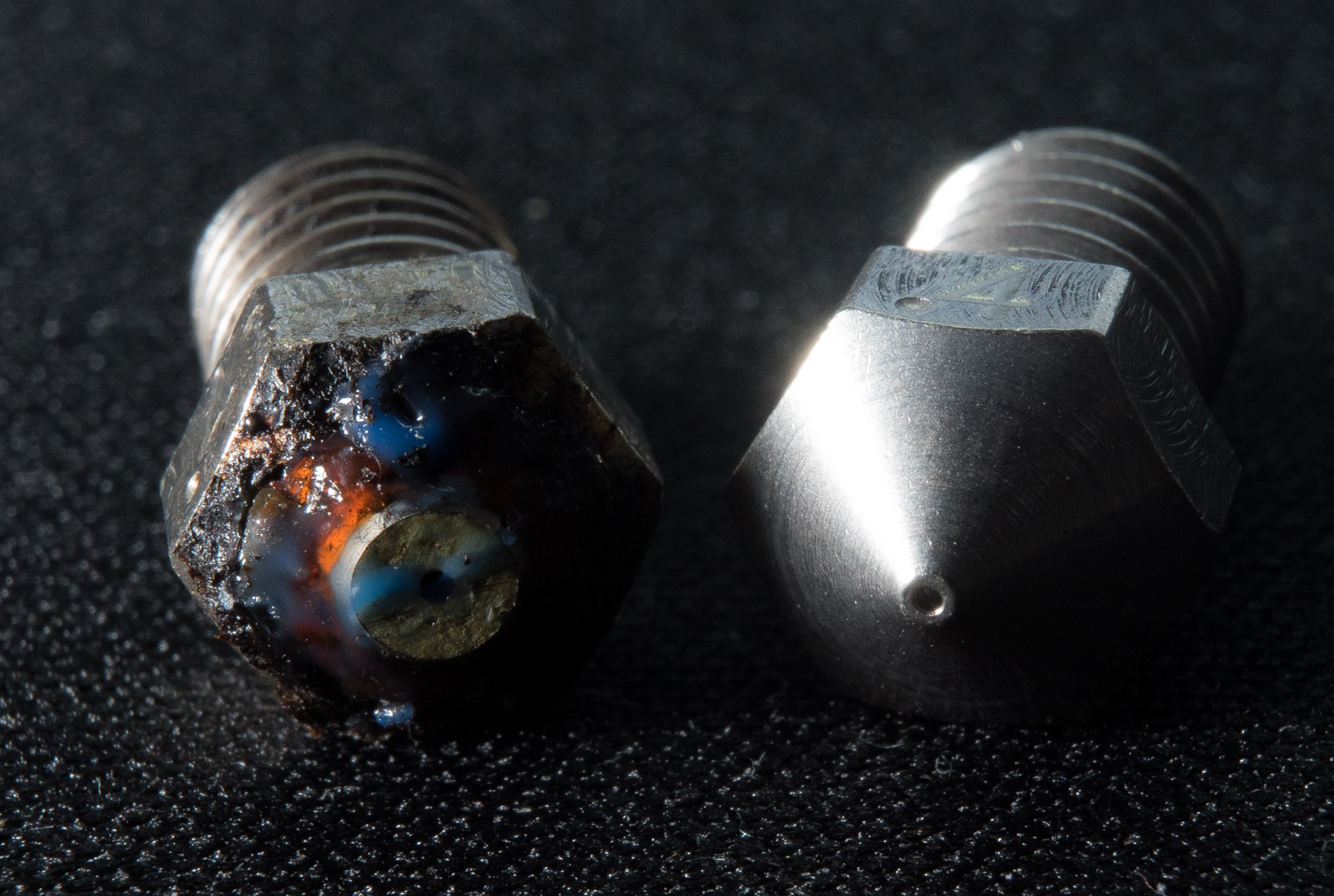

I got the XY-Axis assembly done after some seriously annoying problems. One major problem were tolerance issues which I have already mentioned. I found the cause by accident, i was switching to a .25 nozzle for some really problematic parts (flexible fan encoupling) and noticed the extreme wear of the nozzle. I was printing around three roles of carbon ABS until then. Although i was aware of the abrassive characteristics of carbon filament, i didn´t expected it to be THAT abrassive. I think we need to be careful to use claims like "wear resistance" like micro swiss does when you see something like this after just 3 roles.

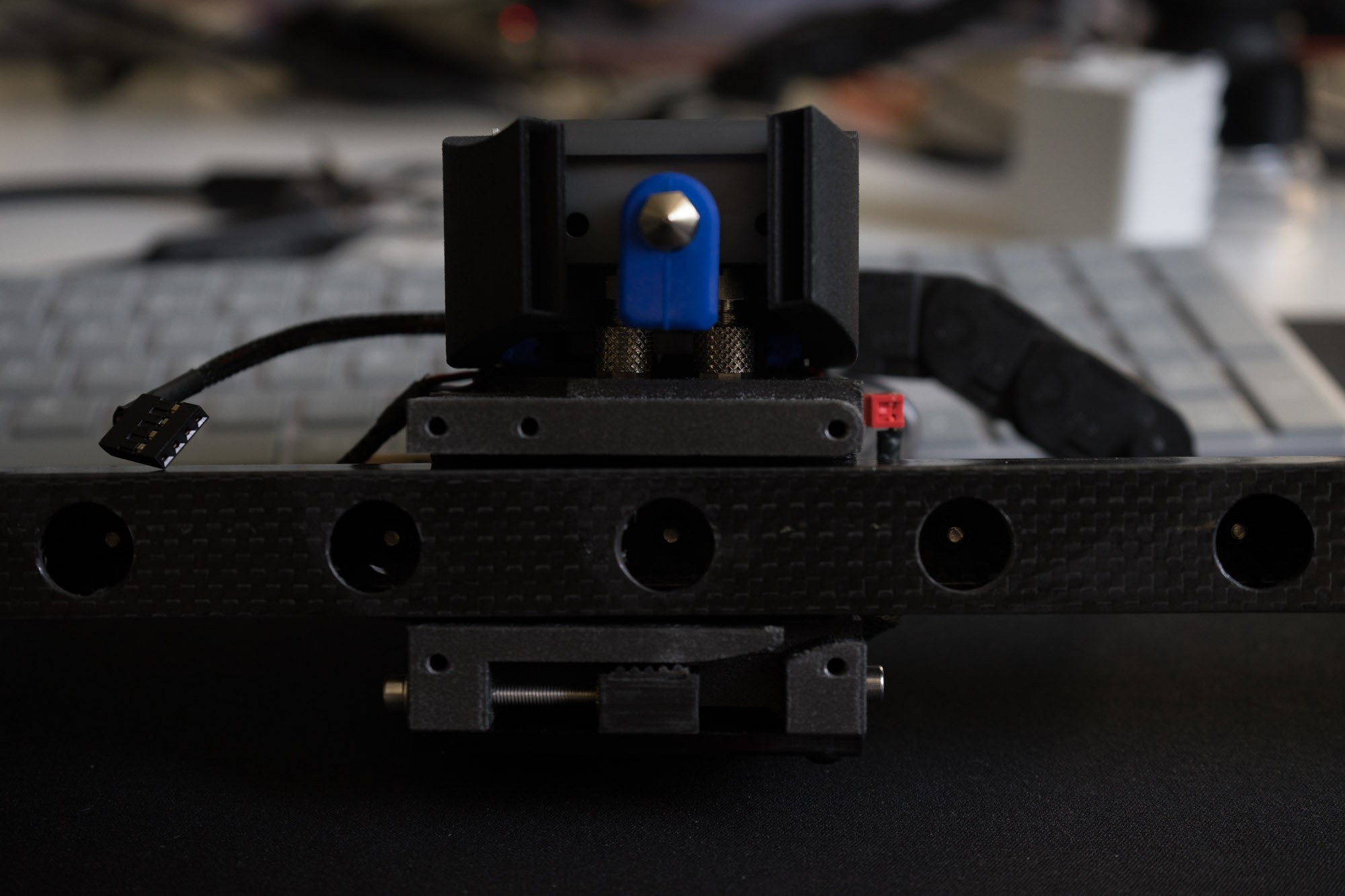

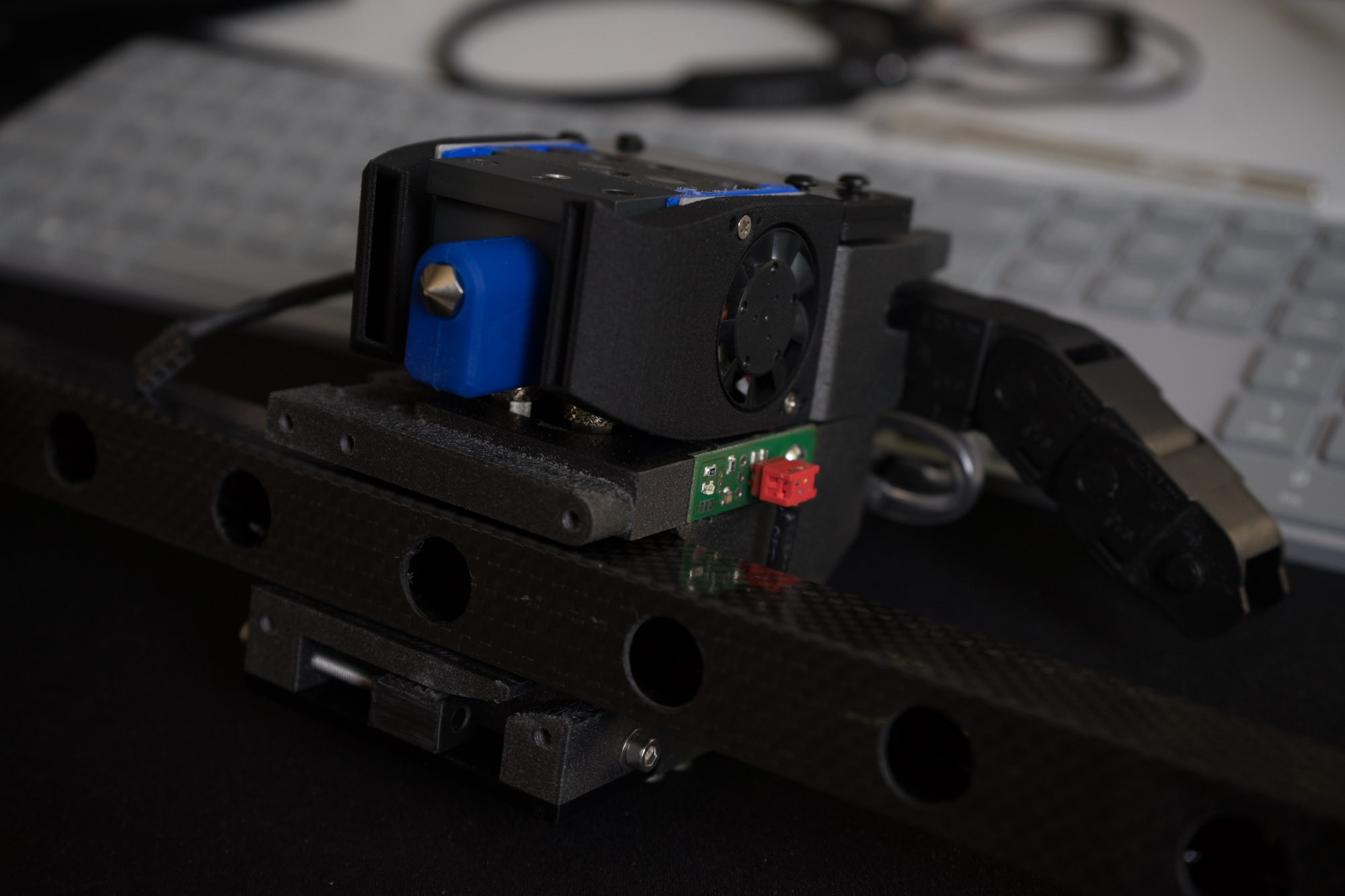

But if you see these tolerances you may understand why i used carbon ABS. The tolerances i build with are very tight and the slightest warping would turn out to be a big problem. The X-Axis/Extruder assembly is the only part where this is REALLY crucial, the rest is fairly easy to Print.

The fans were surprisingly troubling too, in order to get them as compact as possible i decided to ditch the original aluminium housing for a custom sls printed housing/fanduct combination. The backside of the fan is held by flexible printed coupling. This results in a really slim and lighweight partcooling solution.

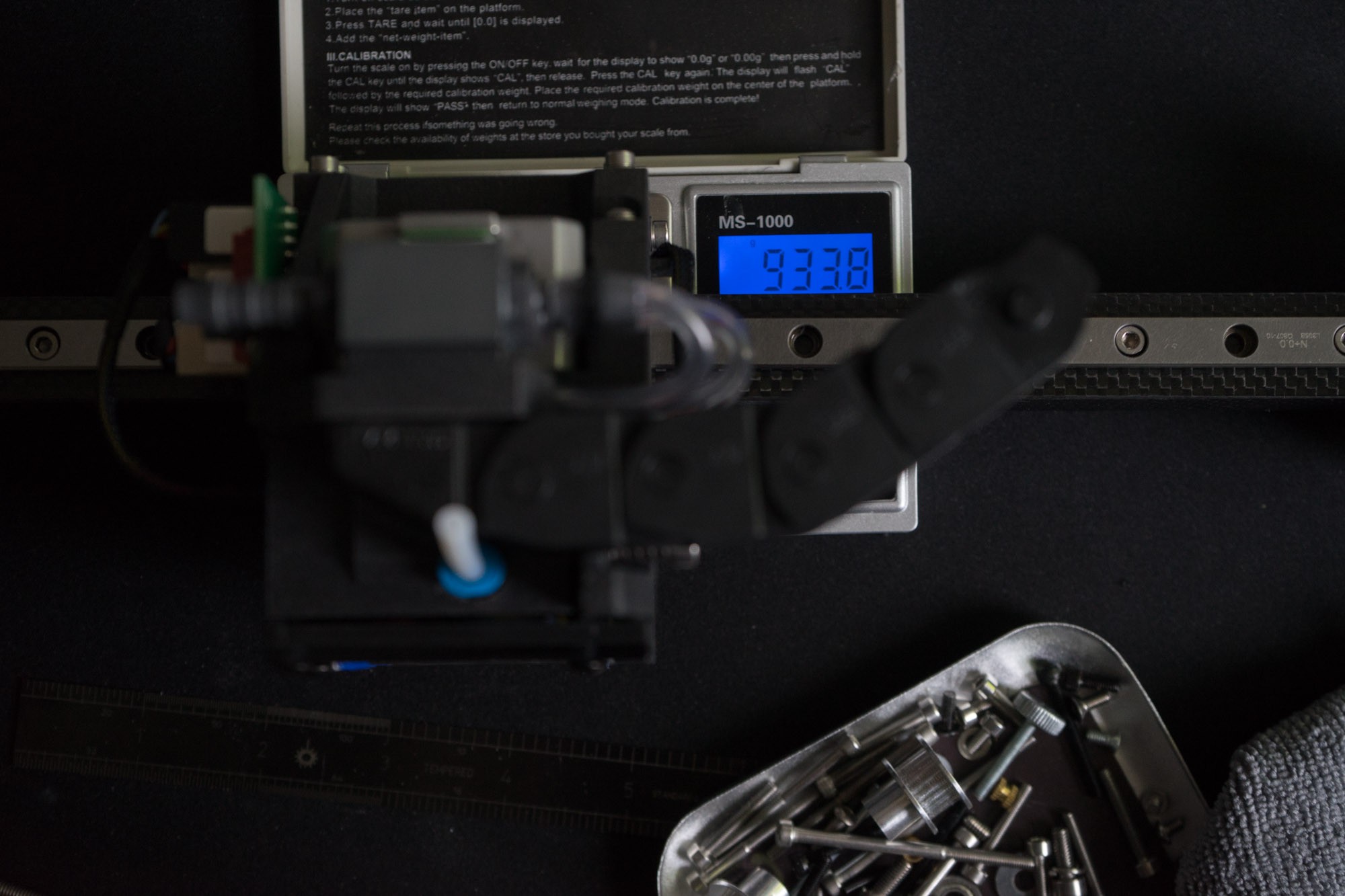

Total weight is around 930-950g, my goal was to stay below 1kg for the complete XY assembly and it looks like I'm gonna achieve that goal.

Marc Schömann

Marc Schömann

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.