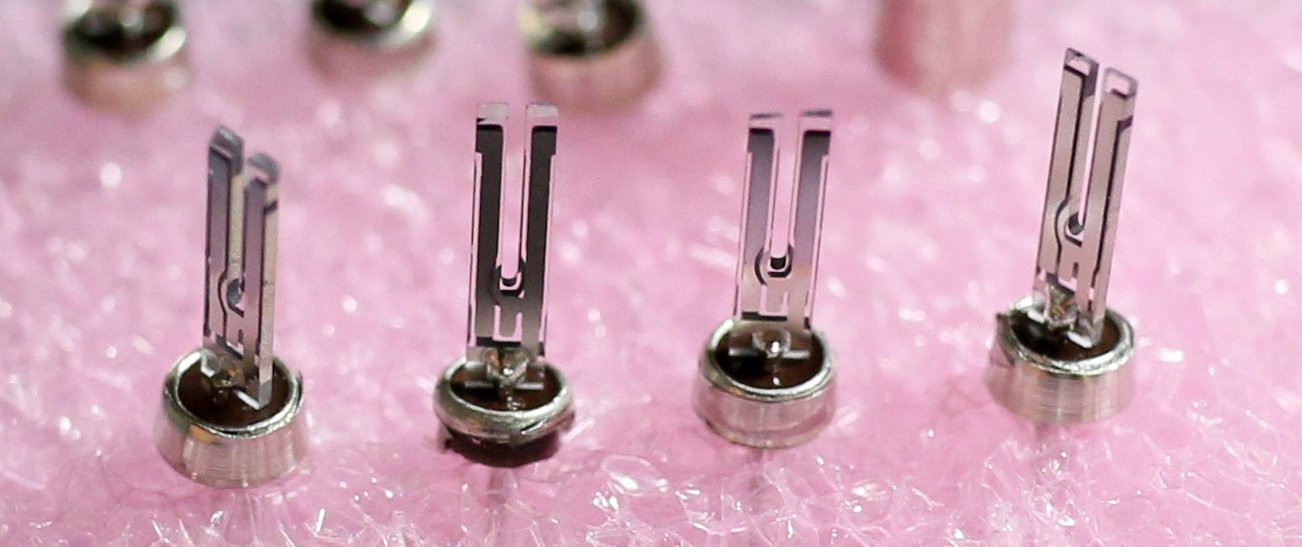

Removing the steel can from quartz tuning forks turned out to be a bit tricky, and I broke about half of the ones I bought. Luckily these things cost only $0.22CAD in 10X quantity, so breaking a few is no big deal.

Chucking the can in a drill and filing the edge while spinning it worked alright, but using a lathe was quicker and easier. I tried at first mounting the base of the can in a drill chuck (on the lathe) so that the fork would remain in the chuck when the can was cut off, but found I couldn't get enough grip on it this way. Holding it in a collet rather than a drill chuck would provide better grip, but I don't have a collet adapter for my lathe. Mounting the top of the can in the chuck gives good grip, but means that the fork falls out once the can is cut off, so the lathe needs to be running at low speed! The forks are very fragile and can easily break from hitting the side of the can once it's cut off.

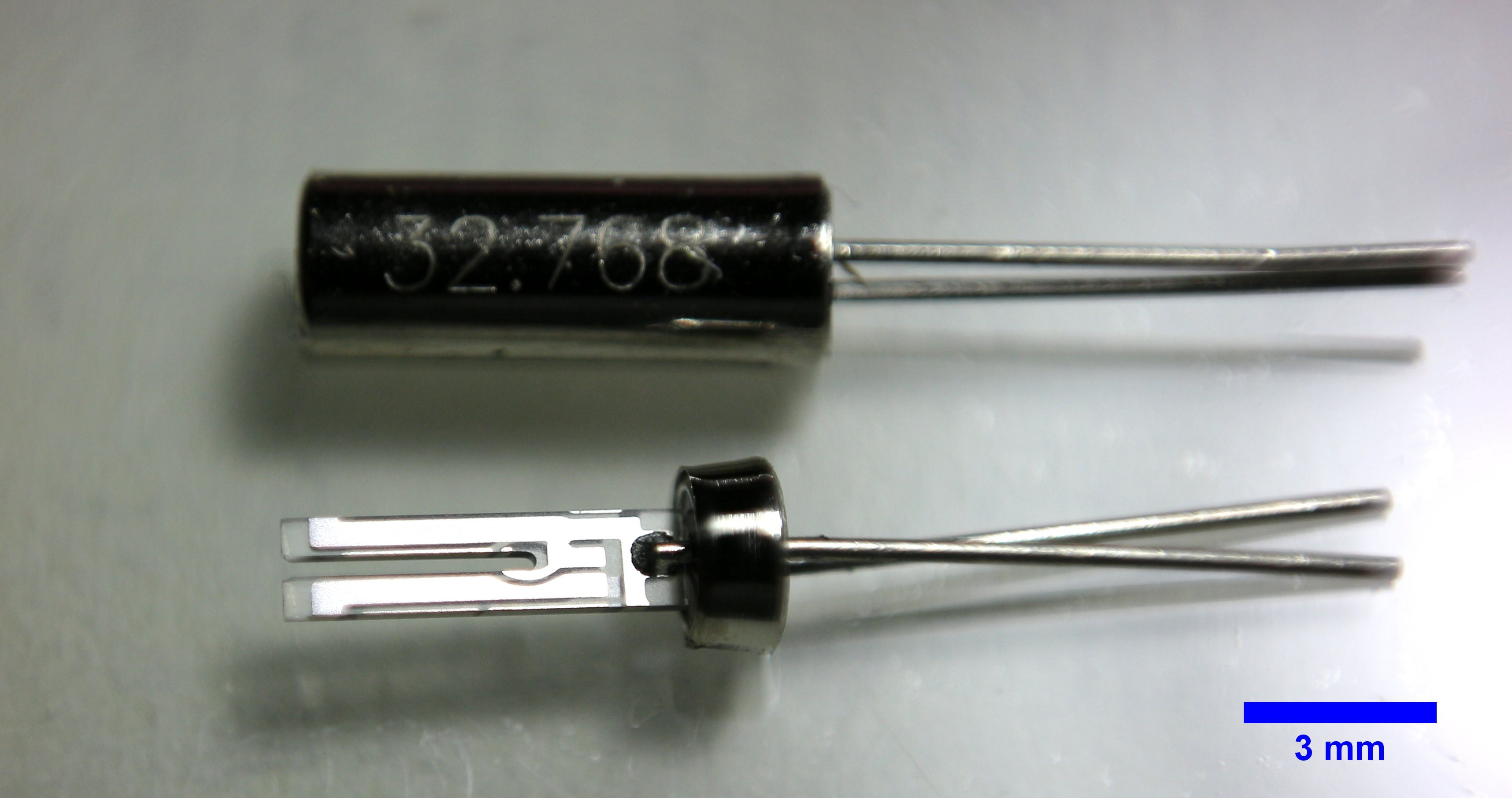

Quartz tuning forks are available in different sizes. The one shown below is ~6 mm long with 4 mm long prongs (digikey link: https://www.digikey.ca/product-detail/en/abracon-llc/AB38T-32.768KHZ/535-9034-ND/675229). Smaller ones are available, but I'd rather start with something easier to handle.

The next step step is to glue one prong to a rigid support. Super-gluing to a small piece of glass cut from a microscope slide turned out to be relatively easy. For the sensing tip, I've been attempting to glue a short piece of 50 um tungsten wire to the other prong. This is the real tricky part! The added mass of the glue will reduce the resonant frequency and Q, and should be minimized. CA type glues don't seem to be suitable for this, so I'm experimenting with epoxies. Positioning and holding the tiny piece of wire in place while the tiny blob of epoxy cures is not trivial! A pair of fine, self-closing tweezers might be good for this.

Dan Berard

Dan Berard

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.