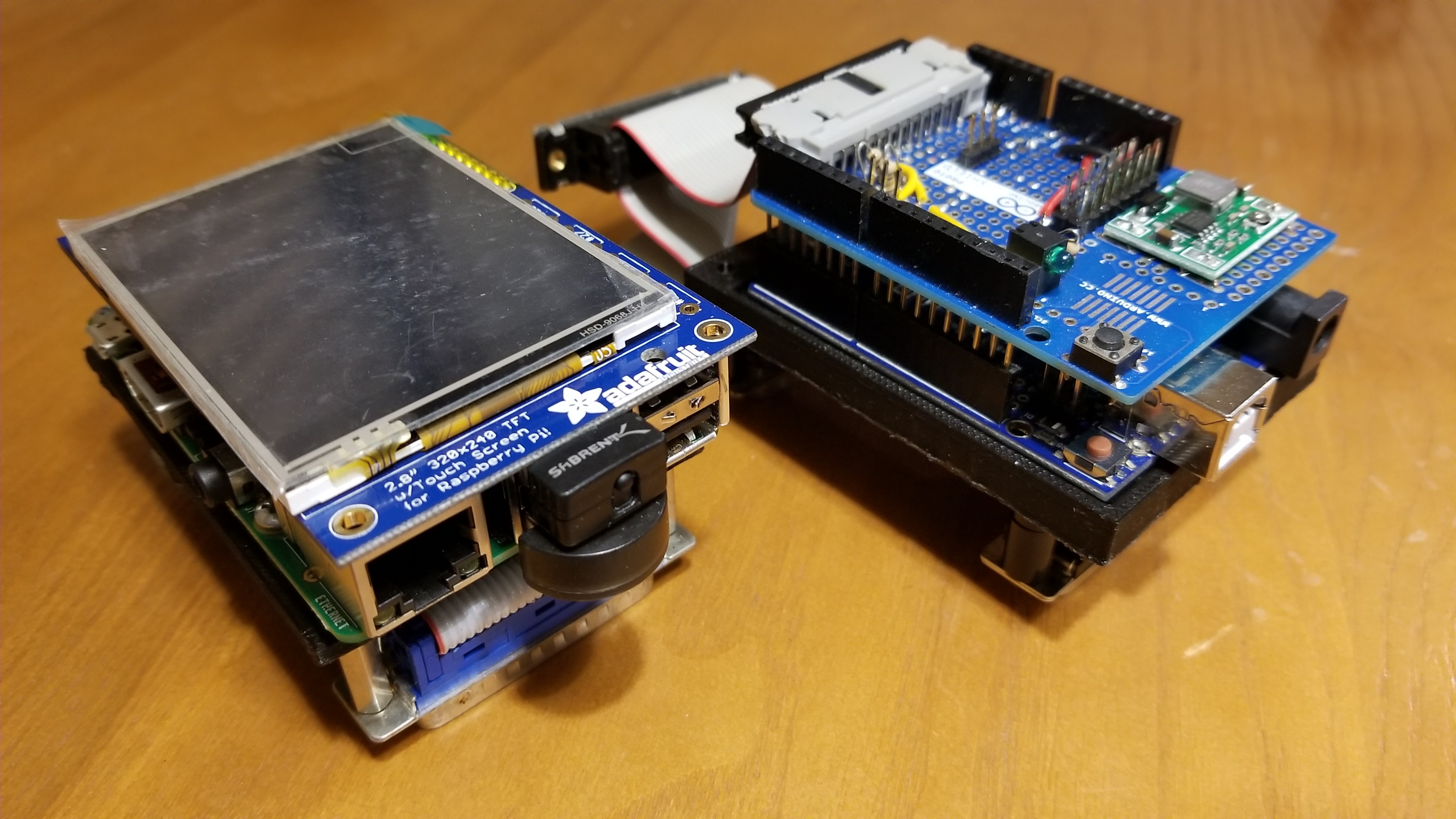

You don't need much to build a Retro Module. For a host module (e.g. one that will house the main microcontroller board), you can start with a female DE-9 Connector. Your first client module would use a male DE-9 Connector. Modules don't need to be enclosed.

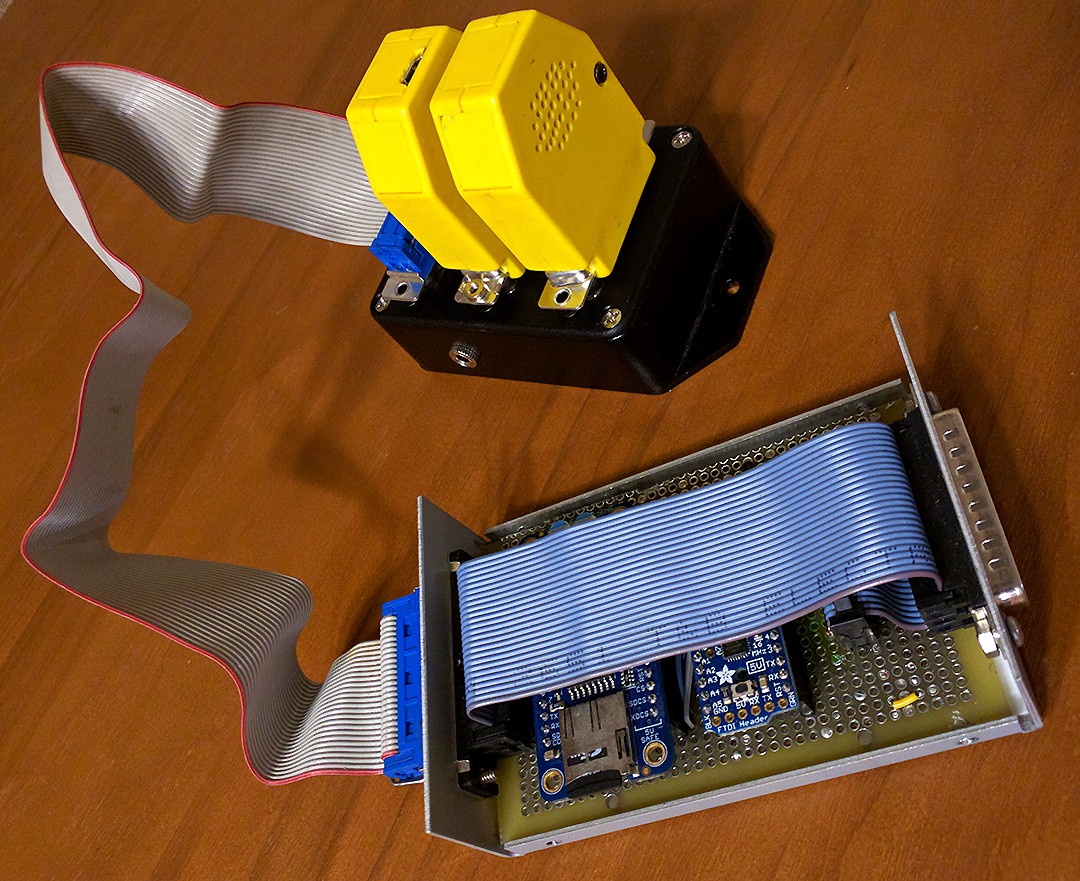

D-Sub connectors like the DE-9 Connector have three major form factors: solder, removable pins & ribbon crimp. Ribbon crimp connectors, though the most expensive of the three, will save you tons of time.

Solder-type D-Sub connectors are the easiest to find & are the hardiest. They do get to be a bit of a pain as you add more wires to the connector.

Consider starting with removable pin connectors. The pins do not require solder to assemble & are easy to move around if there is a mistake. You'll need a D-Sub pin extractor tool if you want to move pins after they've been installed.

Progress:

William

William

Alexander Williams

Alexander Williams

Michele Perla

Michele Perla

Tinfoil_Haberdashery

Tinfoil_Haberdashery

New Pull Request powered up & ready for 3D review! http://retrospec.cc/new