A quick update today about power supplies. It's been an incredibly busy month in the lab, and I've had precious little time to work on OpenCT2 (and even less time to write a proper update).

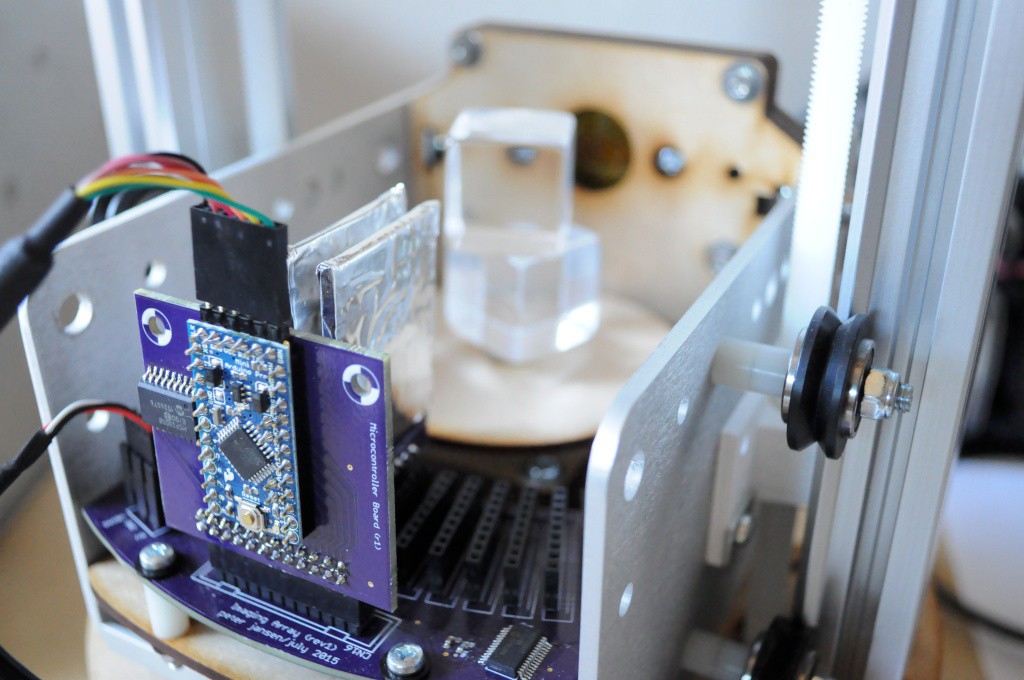

Essentially all of the critical pieces of the system have been designed, but right now the system takes up much of a bench when running -- the unit itself, plus several bench power supplies, a USB hub, a laptop, and a bunch of cabling. I'd like to get everything mounted into the unit, replacing (a) the bench supplies with an internal supply, and (b) the laptop with a Raspberry Pi mounted inside. This should make everything much more compact, self-contained, and allow me to easily do long calibration runs, and evaluate the system performance.

I've been focusing on prototyping the power supply, so that once I have a working design hammered out, I can send off a design to OSHPark and have a compact board that can be mounted inside the unit. The system requires four separate supplies, each with their own requirements:

- Detector Analog Supply (5V): An ultra-low noise supply to power the detectors on the imaging array, and their extremely precise opamps that amplify the incredibly small current from individual x-ray photons to voltage signals detectable by a microcontroller. Right now I'm using a low-noise bench supply for this. The total draw for the entire array will be about 200ma.

- Detector Photodiode Supply (40V): The reverse-bias voltage for the photodiodes on each detector in the imaging array. This also has to be ultra-low noise, and given it's very modest current requirements, I've been using a bank of 4 9V batteries to make sure it's a clean signal. Given the low draw the batteries seem to last quite a while, so I'm okay leaving this one battery powered for now, until an alternate supply can be found.

- Stepper Motor Supply (5V): This powers the steppers for the linear (Z) and rotational (R) axes. The draw is well under an amp, but it generates an extremely large amount of noise. I'm keeping the steppers turned off during measurements, to reduce the noise.

- Raspberry Pi USB Supply (5V): The power supply for the Raspberry Pi, plus the USB devices connected to it (which includes a WiFi dongle, the Arduino Due, and the Arduino Pro Mini). The draw should be limited to 2A, but this line will likely have a lot of high frequency noise on it.

Because one of my main goals for this project is ease of repeatability -- that is, I'd like others to be able to build it without having to source difficult-to-find components or build difficult to assemble boards -- I'm hoping to find pre-made power modules that I can just plug in to an easy-to-solder through-hole board. I'm okay at many aspects of design, but low-noise supplies are one area that I'm not terribly experienced with, so this would help save me a good deal of effort, too.

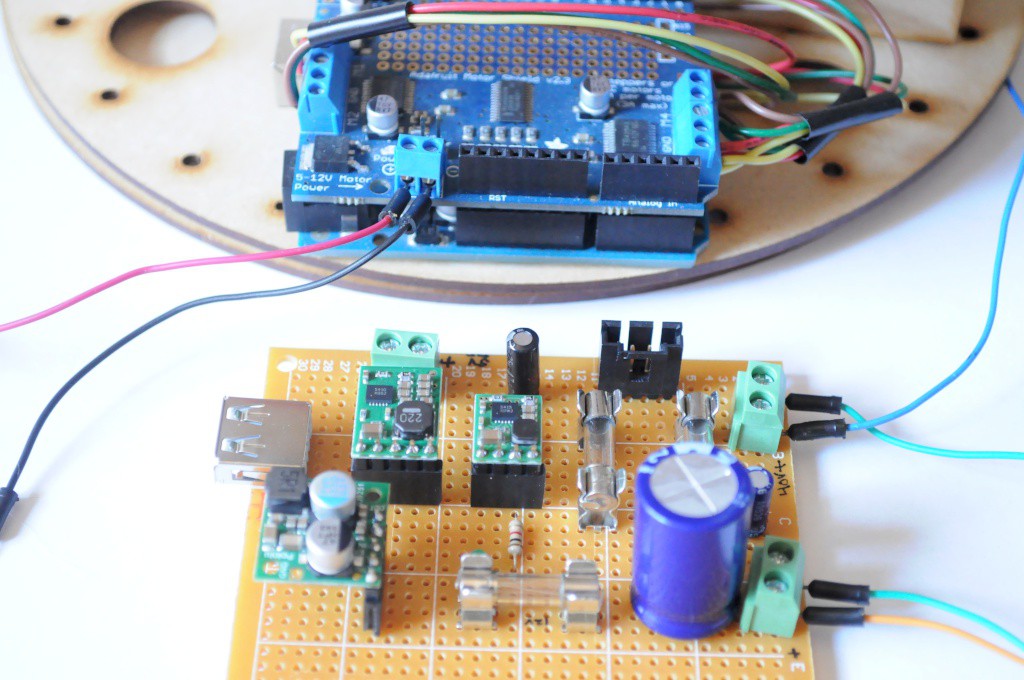

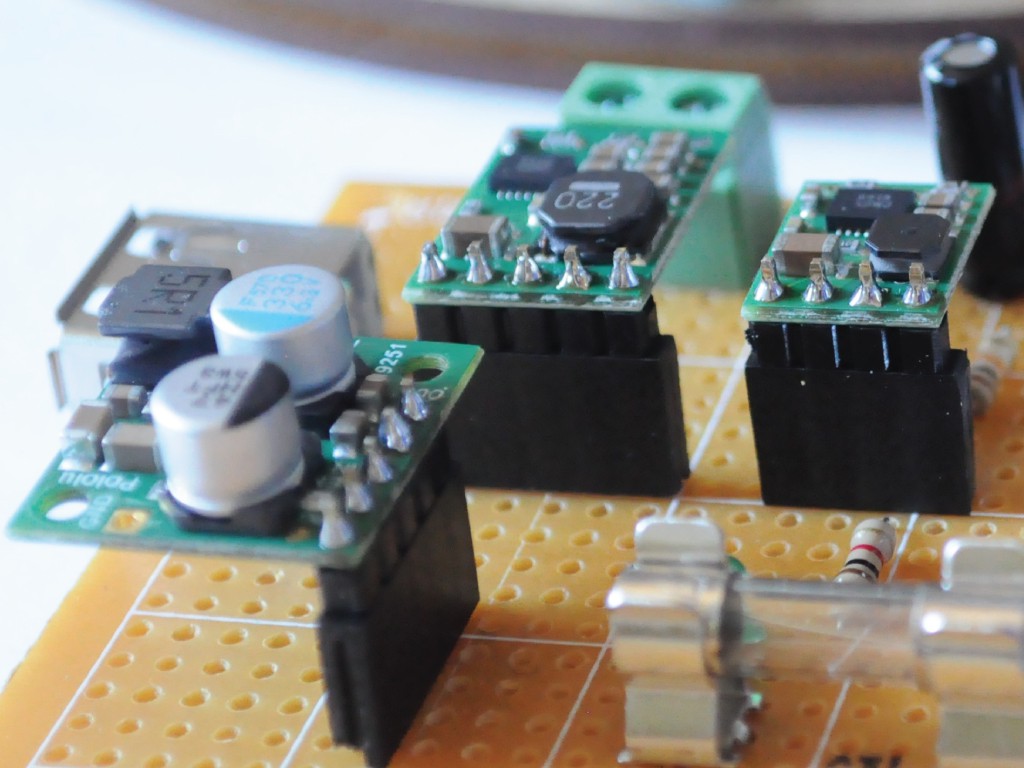

Having never sourced ultra-low noise supplies before, it's incredibly challenging to find economical pre-made modules. Pragmatically, it's also not entirely clear how ultra-low noise the detector supply has to be. In light of this, I decided to try three 5V modules from Pololu, a 2.5A for the Raspberry Pi, a 1A for the motor supply, and a 500ma for the detectors (pictured above). They're all switching supplies, so they will have plenty of ripple to them at the best of times, but I thought I'd give it a try.

It turns out the supplies are incredibly noisy, at least from the perspective of high-energy particle detectors with ultra-low noise requirements, and the detectors register thousands of false-positive counts per second with this supply. Even for the beautifully designed Radiation Watch Type 5 detector that I used in the original OpenCT, I had the most success with powering the detector from an isolated battery -- but I'm hoping that I can avoid that, given that the acquisition times are long, and the draw of an entire imaging array would make battery power impractical.

I then swapped out the switching regular for the detectors with a regular 7805 linear regulator. For all the bad press these get these days about efficiency, and the difficulty with dissipating heat over time, this $0.50 part outputs a relatively clean voltage, and successfully powers the detectors well.

I'd like to not have to relax my "easy-to-source" criterion, but I have found some supplies claiming to be ultra-low noise on eBay (here), based on the TI TPS7A4700. Unfortunately they're coming from the other side of the world, so it'll be a few weeks until I get to test them out. Still, with the results from this quick test, I'll likely end up putting together a design that uses a linear regular for the detector supply -- the supply that is most sensitive to noise -- and use the switching regulator modules for the higher-current and less noise-sensitive motor and raspberry pi supplies.

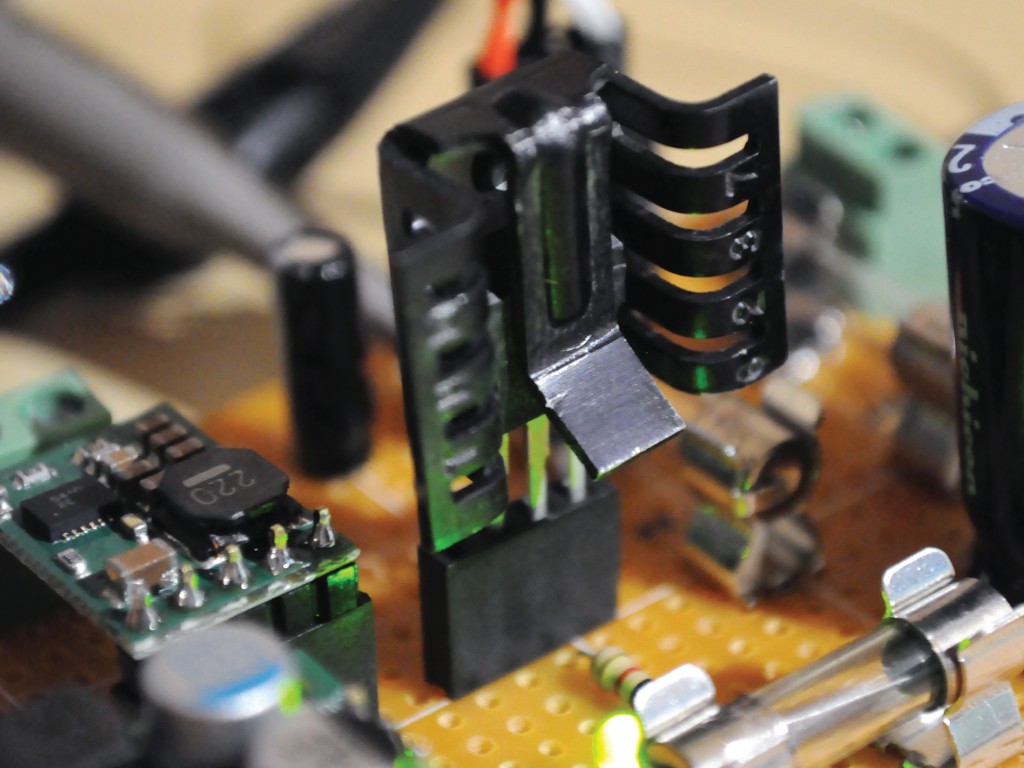

In other news, I had the chance to do another design revision for the shielded radioisotope source holder, and mount it to the carriage. It works great, and putting the source in or taking it out to store takes only a few seconds.

Thanks for reading!

peter jansen

peter jansen

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hi Peter,

If you're not averse to surface mount components, I recommend the LT1761-5 as an excellent low-noise 5V regulator. Also, you can't go past a good solid ground plane :)

Are you sure? yes | no

Hi Andrew,

Since I'm aiming to make this as easy as possible for folks to build, I'm trying to steer away from surface mount components for whichever boards that's viable for. The detectors have large-pitch surface mount components, but I'm going to try and make the power board entirely through-hole, if possible. My other open source designs have taught me that each 100-pin TQFP or leadless part I place on, I lose most of the audience of potential makers. We'll see how well I do with this one!

Are you sure? yes | no

Maybe you could mitigate the audience loss by pointing towards some of the youtube tutorials on surface mount soldering? It's not as scary as people think it is, in fact I've hosted a few small practical classes as part of a makerspace and I haven't found anyone who has had difficulty after they've been shown how.

I also suggest you ditch the vero...I think a project as neat as yours deserves nice multilayer PCBs :) It will help immensely with signal integrity.

If you really want good quality throughhole power modules though, I suggest you look at Tracopower. I've had some success with precision analogue boards using these supplies (followed by linear regulators, of course).

Hope some of this helps, and I don't mean to tell you how to suck eggs :)

Are you sure? yes | no

SMD are not hard, as long as it is reasonable :-)

There is obviously a difficulty gap between a 1206 resistor and a TQFP100 part. SOT23 is not hard, 0603 is annoying (some can hide in the through-holes of the PCB hahaha) but today, I use less "classic" resistors, except when I also need a jumper.

The keys are the placement of the part, a well controlled tip temperature and some good flux.

Of course I'm not speaking about QFN and BGA... but 1206 capacitors and resistors (even 0805), and SOIC (1.27mm pitch) are nice (once you understand that capillarity is your friend)

You also wrote : "I've been using a bank of 4 9V batteries to make sure it's a clean signal."

Look at the "audiophile" community, I've seen noise spectra of batteries and some are a bit counter-intuitive (sorry, I forgot the URL). The audio engineers have come up with pretty smart devices but in the end, you are the one that has to test each part's qualities and behaviour.

I have had noise issues with voltage references, for example, and even with zero load, they require significant passive filtering (one or two LC layers for the output). The 7805 is a very old design, not aimed at low noise so I hope you over-filter its output as well, using alu caps and large ceramic caps in parallel.

Good luck !

Are you sure? yes | no

Have to watch out for ceramic cap and 7805. Regulators like the 7805 were designed way before low ESR MLCC, so they can be unstable and goes into oscillation. The worse part is that the datasheet do not even have specs for the stability limits. There are better parts out there. e.g. lp2950 available in through hole has noise specs, impedance plot etc.

SMT is easy if you do it with a proper PCB. I have moved to 0402 and smaller parts these days. I don't even use stencils. :)

Are you sure? yes | no

:) You're all preaching to the choir, I'm not the one you have to convince about the merits of surface mount components. But as a frequent author of complex open source designs, part of my educational goals for this project are for me to learn how much reducing the skill barrier to entry affects adoption.

There are so many open source hardware projects that are functionally open in name only -- the barrier to making them is just too complicated for even exceptionally skilled folks. With each project I try to learn how to become a better open source community engineer and reduce that barrier as much as possible, hoping that one day I'll be able to figure out the empirically-determined recipe to take a project from a few people actively engaged in building to tens or hundreds -- even for projects with a high component count, like the ones I author tend to be. Then I hope I can share that recipe. Open hardware is still somewhat new, and we're still figuring out how to do it well -- and part of this project isn't figuring out how to design a CT scanner that I can build, it's figuring out how to build one that almost anyone with modest making skills can put together.

And, thank you for the regulator recommendations -- you're definitely right, many 7805 datasheets don't include noise specifications! (But, at least it seems to work, in practice). The lp2950 looks like a great part, too -- would you happen to know if it comes in something that can source 500ma or >1A?

Thanks!

Are you sure? yes | no