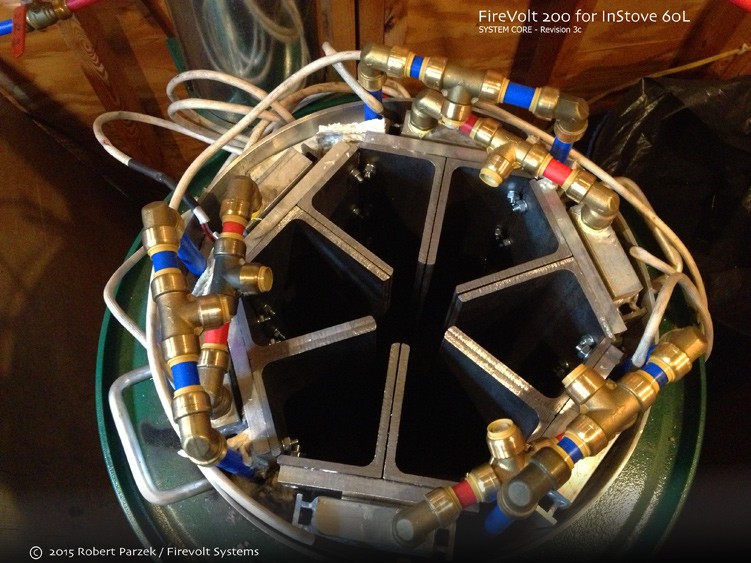

A brief rant on the properties of base metals and heat transfer. From a practical angle, the FireVolt prototype design revision 3c incorporates a great deal of thermal isolation and a range of ferrous and non ferrous metals, jacketed by the InStove's insulation and a steel shell. To say it another way; "This thing doesn't radiate heat very much" and you can run it, indoors, full-tilt on a hot day, with nothing but a vent fan on in the room to maintain ambient temp. The rest of the buildings temps are virtually unaffected because the InStove itself is highly concentric and insulated, as is the FireVolt Core. (You can also choose to run it outside, but a small weather shelter is highly suggested for outdoor installations).

(the above cross-section is of an un-modified InStove)

(the above cross-section is of an un-modified InStove)

Where you actually put the harvested heat (harvested via water riding the 1/2" PEX plumbing) is up to you. For these warmer months I'm operating a water holding tank, a mini cooling tower in essence, outdoors as a thermal diverter. Once the buildings' domestic hot water tank is brought up to 110 Fahrenheit, and the building itself has no further heating requirements (signaled via thermostats) - the excess heated water is cycled into a large open-top tank which radiates to the open air outside. There are better (more conservative) ways to do this, but it works for now as a robust thermal dumping ground while I've been pushing into high temperature test cycles.

In the warmer sunny months the system gets run at night usually, as it delivers a steady charge to the buildings' 12v LiFePo4 battery array at a time when Solar is useless.

But - back to the Thermal Mass vs. Thermal Conductivity topic;

The current core material, Carbon Steel "Angle Iron" - has a rather nice thermal mass but a poor thermal conductivity compared to, say, Aluminum. However, core firebox temperatures can hit 1000c and the slow but steady creep of that heat - through the steel, eventually hits the TEGs hot side Aluminum plate, and things really start to get interesting about 45 min after startup, full power is usually hit around 1.5 hours.

Another interesting thing related to the Steel core. After the firebox flame goes out (due to fuel starvation) the system continues to produce highly useable power for 2 hours on cool-down., again because steel conducts heat poorly, but there is so much of it, you get this nice long discharge profile on cool down. Now, when the next re-pack of the core takes place I may swap the Carbon Steel for Aluminum and all of you Thermodynamics gurus can imagine what that'll yield for a temperature Delta between my hot and cold sides : D - thats why theres a cooling tub outside! eventually I think it may end up as a pool. Year round. We'll see.

Rob Parzek

Rob Parzek

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.