Circuit

As mentioned, the main processor is an ATMega88 which runs on it's internal 8MHz oscillator.

The power supply is backed by a 220µF capacitor originally intended to last just long enough to transfer all data to the EEPROM in case of power loss. With the new firmware it will last up to eight minutes when sampling at one sample per minute.

The DS1337 RTC is backed by a separate 220.000µF GoldCap. It provides both date and time as well as a one-minute interrupt to trigger a new measurement. It shares the I²C bus along with the 1MBit EEPROM and the HYT939 sensor. To minimize current consumption, external 100k resistors were used as pull-ups for the bus, in my tests they were still sufficient up to a clock rate of 400kHz. Using such high-value pull-ups is not recommended but with such short traces it does not matter too much.

The LCD and the contrast-setting potentiometer are powered from one of the ATMega's pins, so they can be completely powered off and don't drain current continuously.

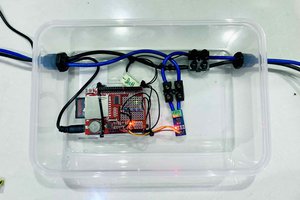

PCB

The PCB was fabricated on a Shapeoko 2 CNC machine, the layout is single-sided with just nine jumper links.

I used many SMD components, the main processor is housed in a TQFP-32 package and all resistors are 1206s.

I managed to fit all components on a 50x85mm sized PCB.

Case

The case is made entirely from 4mm thick plywood and was also routed on the CNC machine. It uses finger joints and is held together with glue.

It is divided into two sections, the main section for the circuity and a battery compartment with a sliding lid.

The back plate is a press-fit for easy servicing.

Software

The software underwent a complete redo, so I included information on both the original and the updated version in the project logs.

PC Software

Right now, the software used to receive and process the data on the PC is pretty crude but works so far.

It is written in C#.

The data can be saved to either a .csv or to a html file which uses HighCharts to plot the data

martin2250

martin2250

iSax

iSax

Jan Waclawek

Jan Waclawek

Sebastian

Sebastian

Thanks for your great write-up! A datalogger with extremely low power cumsumption is one of my next projects as well, I had some of the ideas in mind which you already tried. Thats great, now I know it´ll work.

Cheers!