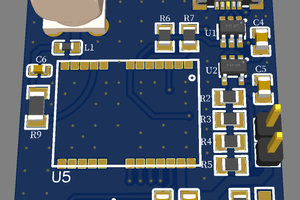

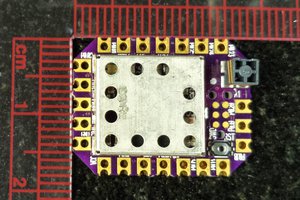

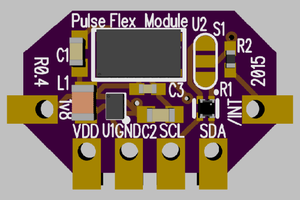

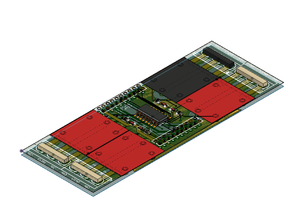

Utilizing flex PCB, we will produce Flex Module variations that are easy to sew utilizing a sewing machine. We will attempt to design direct sewable water resistant rigid-flex variations as well as provide for a snap button removable design.

If there is enough interest, we may make them available for purchase on Tindie as well.

We are sourcing better conductive thread. We are working right now with the stainless steel thread most wearable makers use. We also have some silicone covered wire coming from China to test with as well. We are hoping that the design will be both hand and machine sewing compatible if we find a good conductive thread that goes can fit in a needle. The 32AWG silicone wire will lay in a bobbin and can go through a very large machine needle (yet to find one though).

Any software related will be released under BSD or MIT license. SAAS or cloud based software will be AGPL. Chris Hamilton

Chris Hamilton

Marek

Marek