General Concept of UFARM

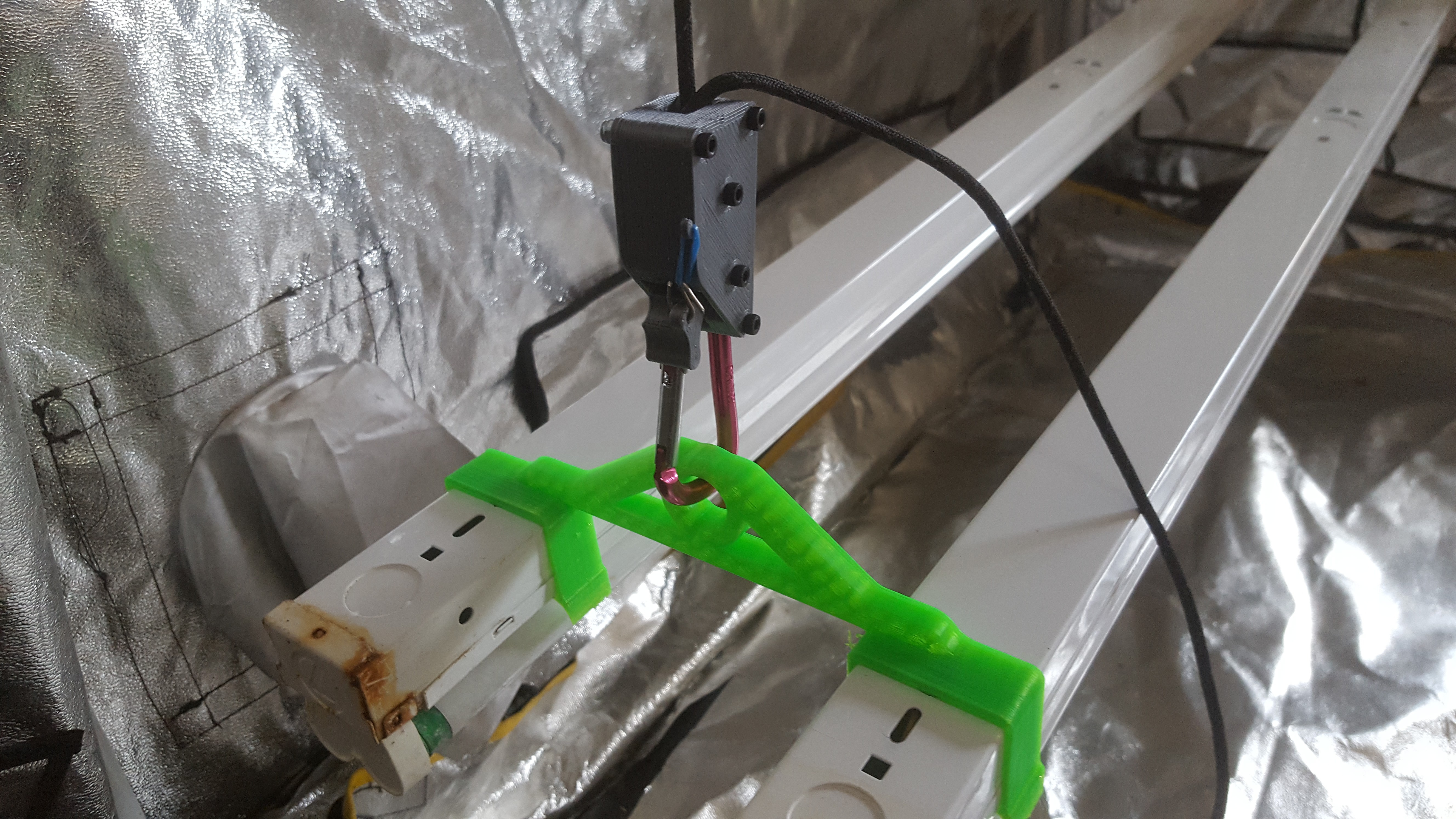

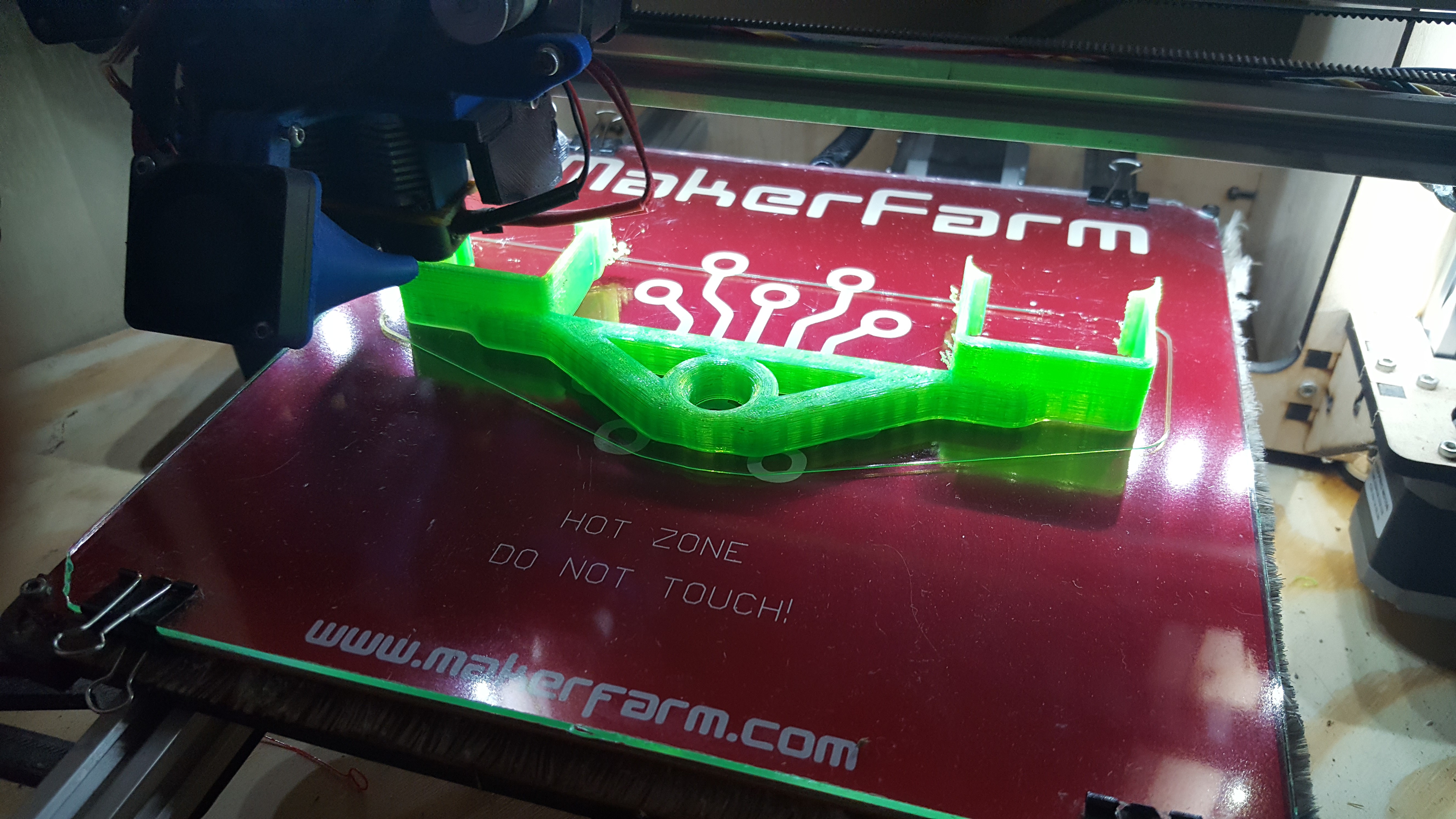

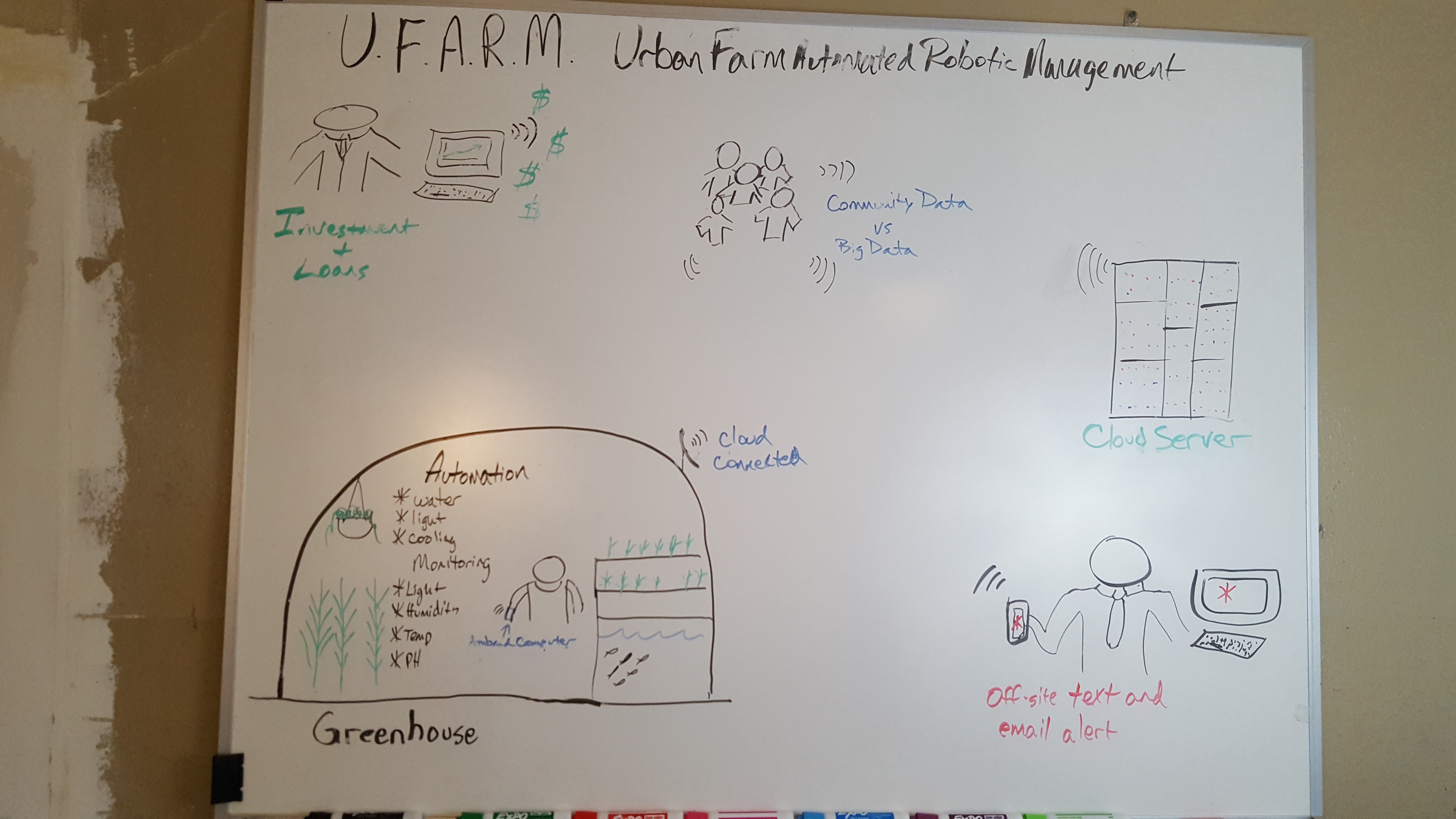

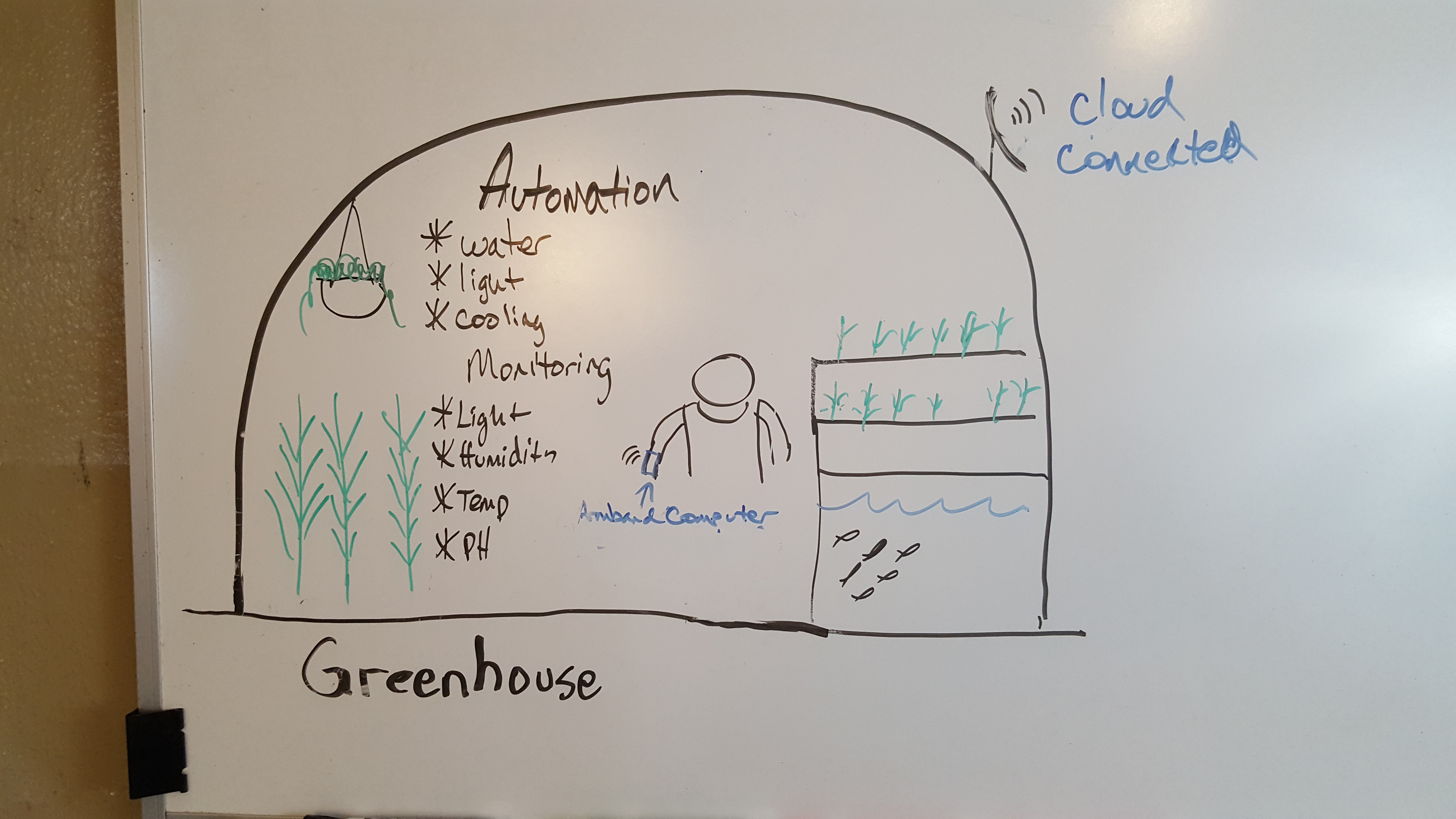

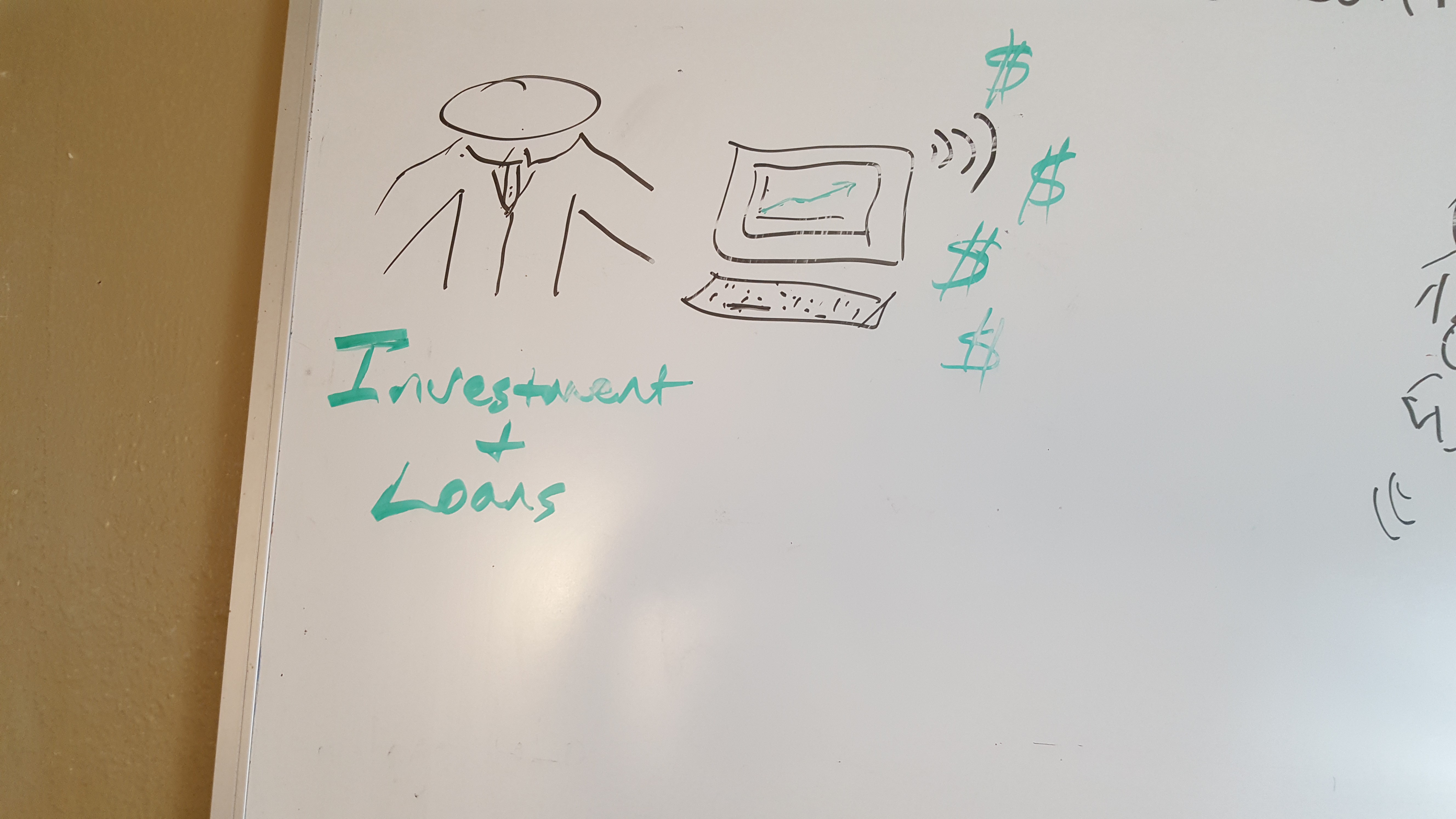

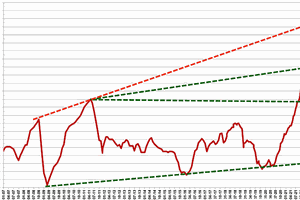

UFARM is an app and complete set of tools to lower the physical and economic barriers to farming and gardening. Automating the feeding, watering, and environmental control we ease the process of successful plant growth. At the same time we can log data of production and costs. The accumulated data will aid the entire sector of urban and intensive farming by providing a clear picture of profits, costs, and use of resources to gain loans and investment for growth.

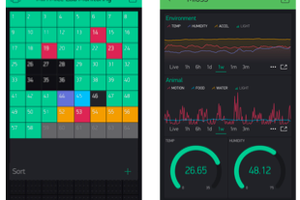

Microcomputers, such as the RaspberryPi, monitor, control, and route systems and data automatically through a network of sensors and nodes. Data is accumulated over a period of time. Users can then access and utilize the information through an app and web portal for scientific and economic purposes.

It is related to my robotics and farming work that I have been involved with separately. for the last decade. I have lead aerial robotic technologies and embedded systems research for the last several years. In the meantime, I have moved my family off grid almost five years ago. While growing our own food, we teach about creating local production and distribution systems in food deserts around my community and throughout the country.

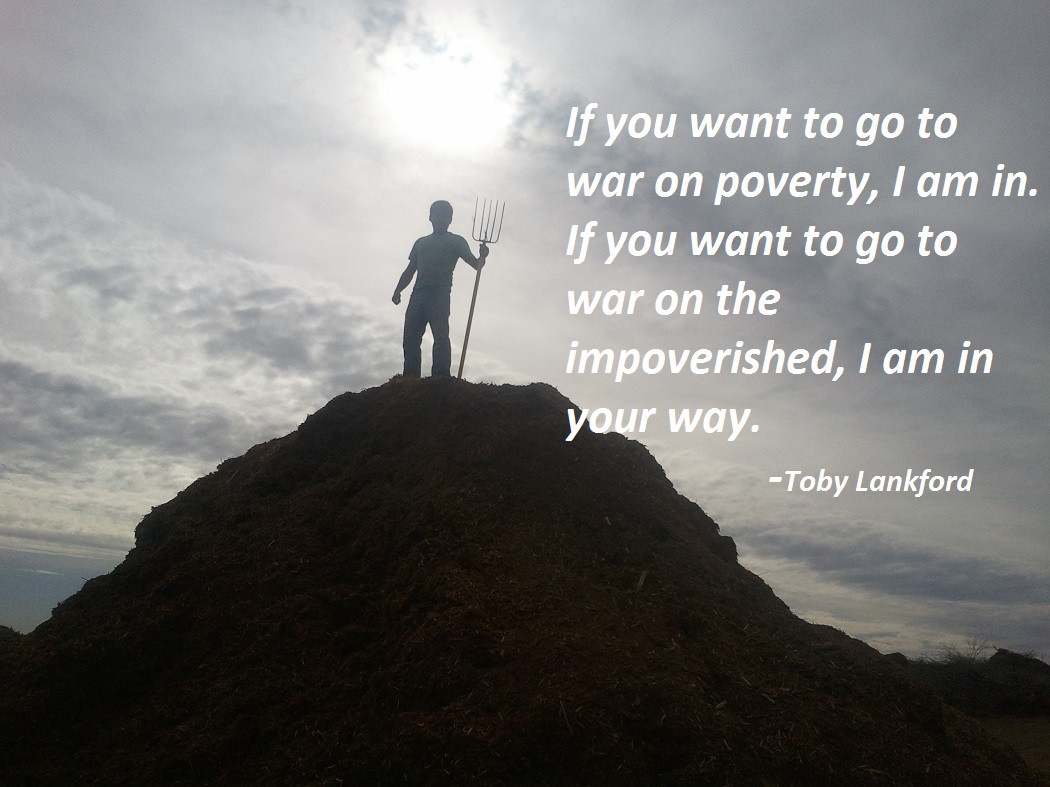

We will be improving automation and robots through faster processors, superior code and integrated design. What separates UFARM is the accumulation and use of data to identify and quantify trends and correlations. Without this body of data, accessible financing will continue to elude the local farm movement. I have watched too many good people and good ideas go unfinanced because of this lack of empirical research. Like any other startup farming requires adequate front end financing to succeed. Without access to these resources, our food system and the crisis of child poverty will slip into further decay.

UFARM is a positive step to food security and accessibility. Improving access to production research, lowering the barrier to successful production, and quantifying clear reductions in costs and resources will provide a foundation for future farmers and producers to grow. tlankford01

tlankford01

Community Data Vs. Big Data: Companies are already using data against consumers in many ways. A prime example is that seed companies sell rapeseed at a much higher rate to farmers in Illinois than they do in Texas. In Texas, costs more to produce for smaller yields. So the farmers in Illinois are punished for growing higher yields. They are forced to give more of their margin to the seed company. With UFARM we are building community data. The data will always be accessible to everyone on the network. The vital growth and consumption data is graphed charted and shared to all so that each producer can use it to maximize there yields while lowering their costs.

Community Data Vs. Big Data: Companies are already using data against consumers in many ways. A prime example is that seed companies sell rapeseed at a much higher rate to farmers in Illinois than they do in Texas. In Texas, costs more to produce for smaller yields. So the farmers in Illinois are punished for growing higher yields. They are forced to give more of their margin to the seed company. With UFARM we are building community data. The data will always be accessible to everyone on the network. The vital growth and consumption data is graphed charted and shared to all so that each producer can use it to maximize there yields while lowering their costs.

Lex Kravitz

Lex Kravitz

minifig404

minifig404

That is interesting. I was trying to visualize the linear space that you be needed for creating this as we have replicated this in greenhouses as little as 20 x 25. What would be the argument for calculating in cubic feet in comparison to floor space and just assuming additional space for human traffic and maneuvering? Thank you for your input and interest.