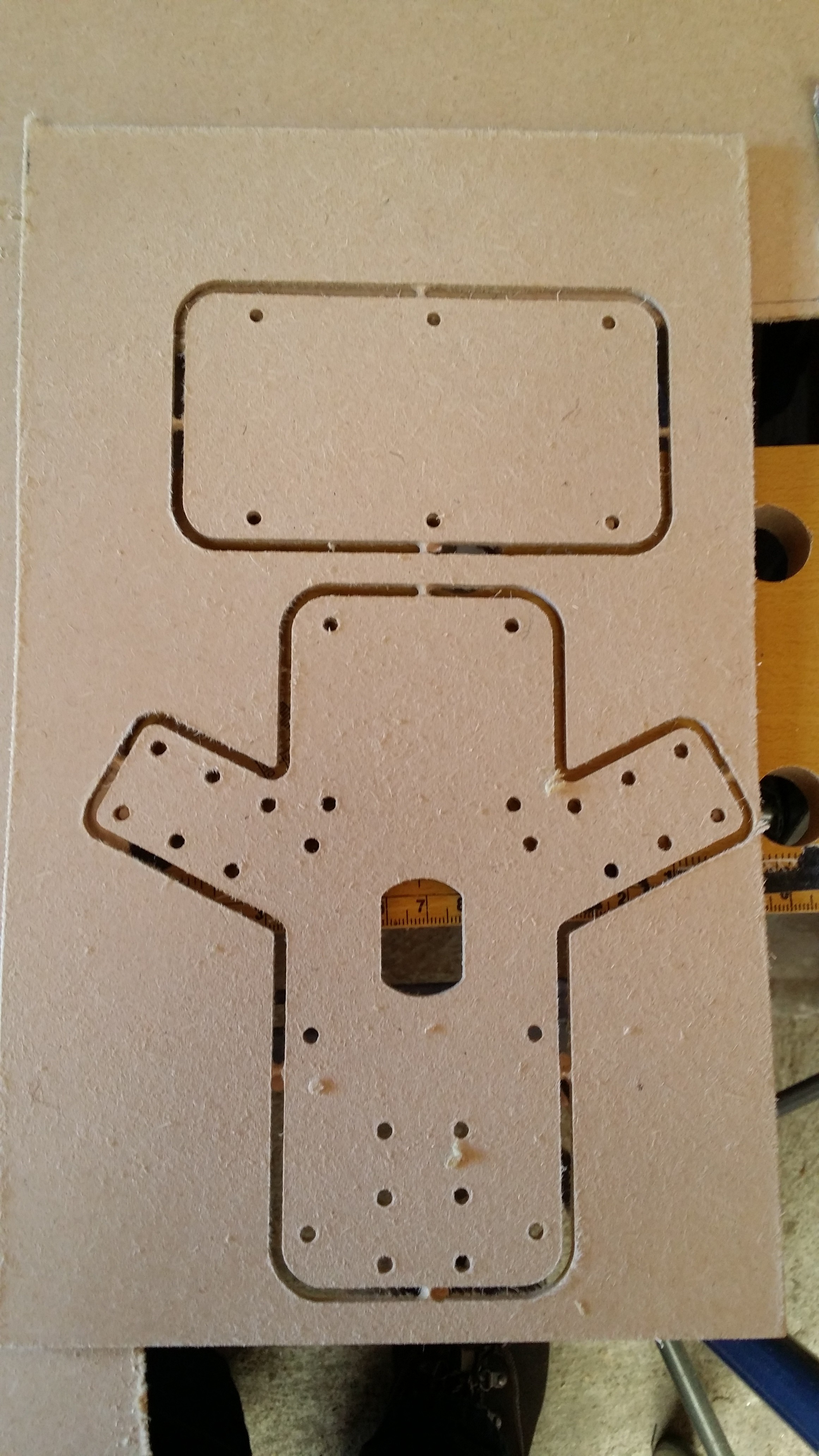

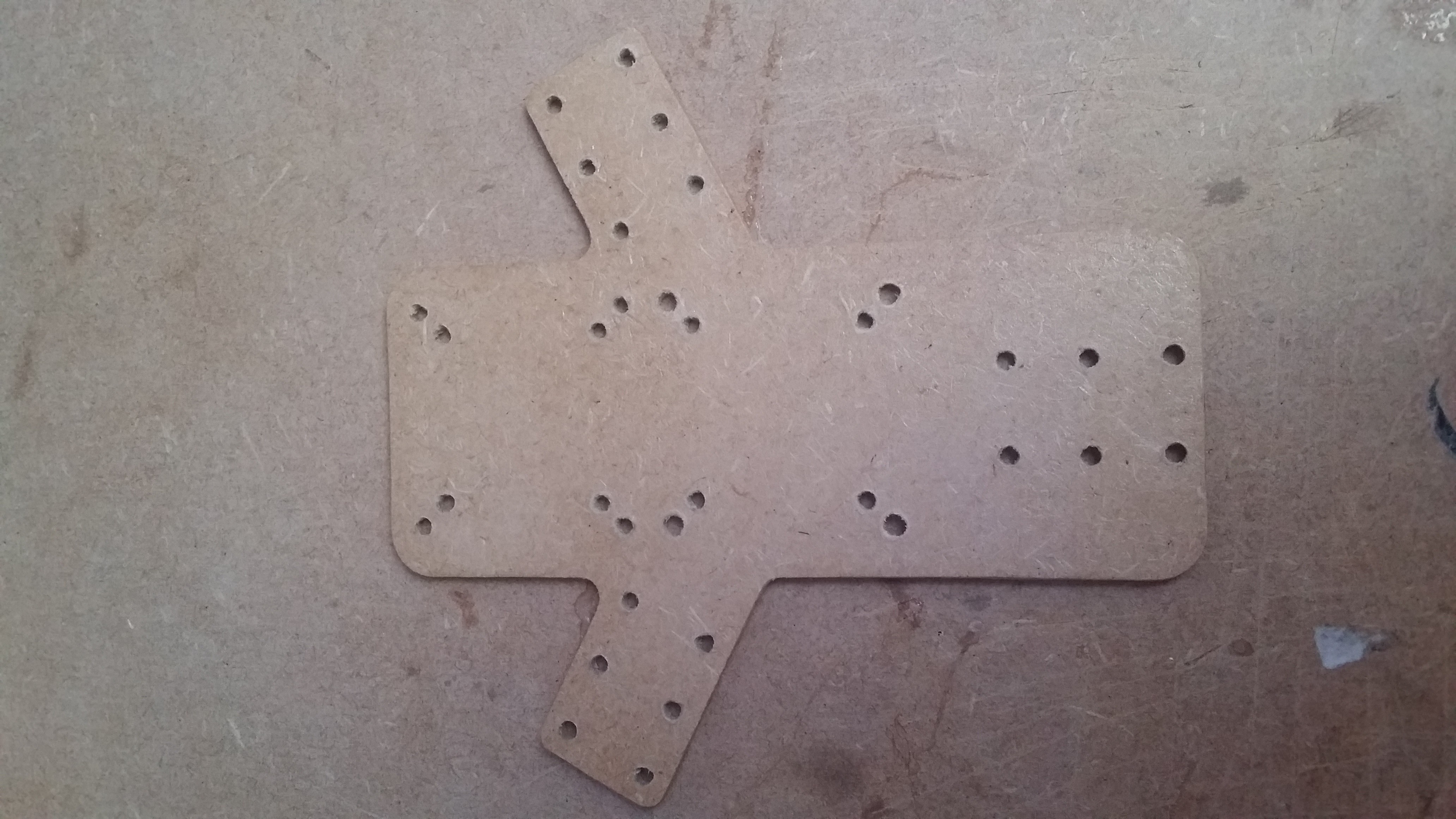

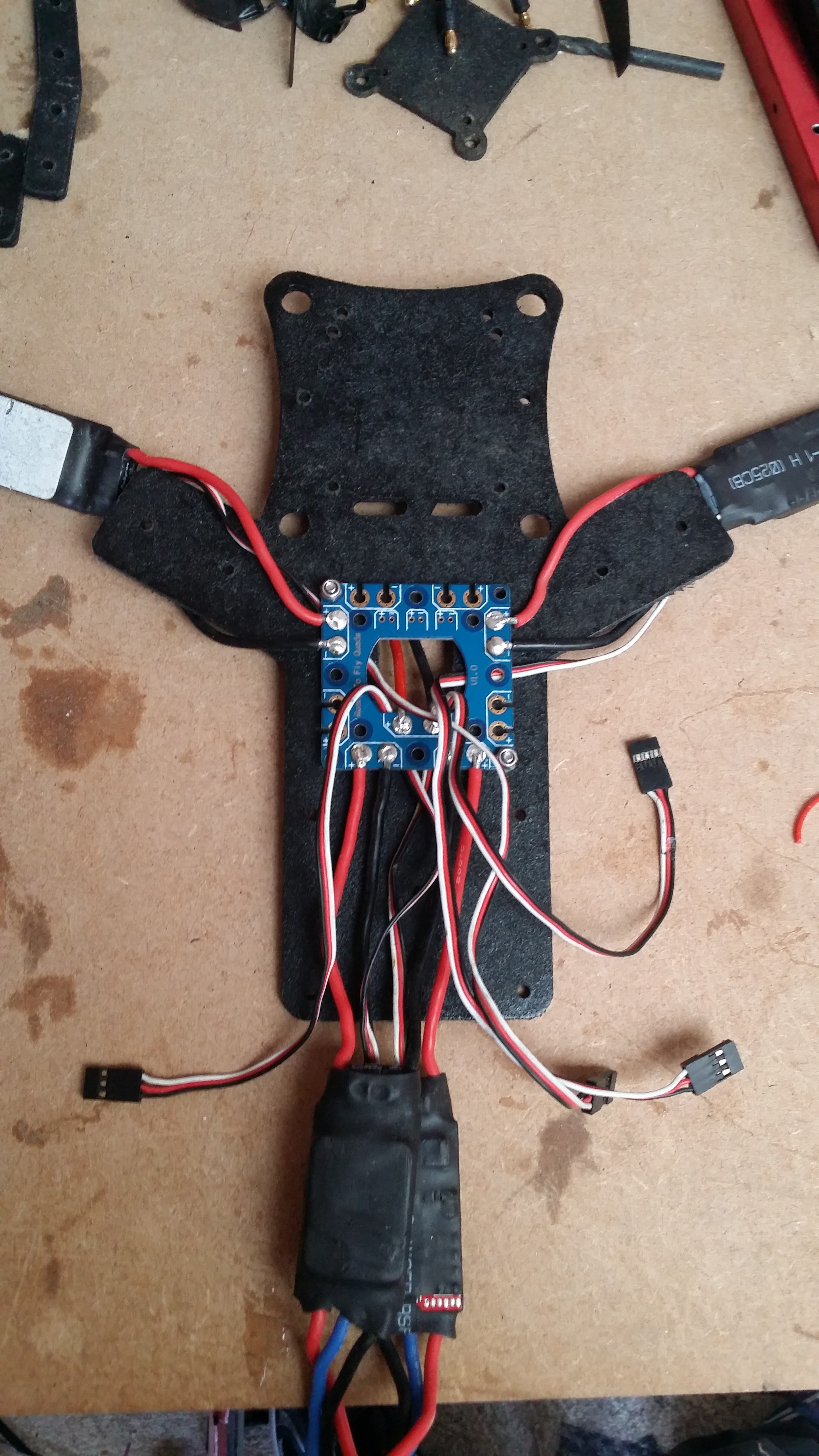

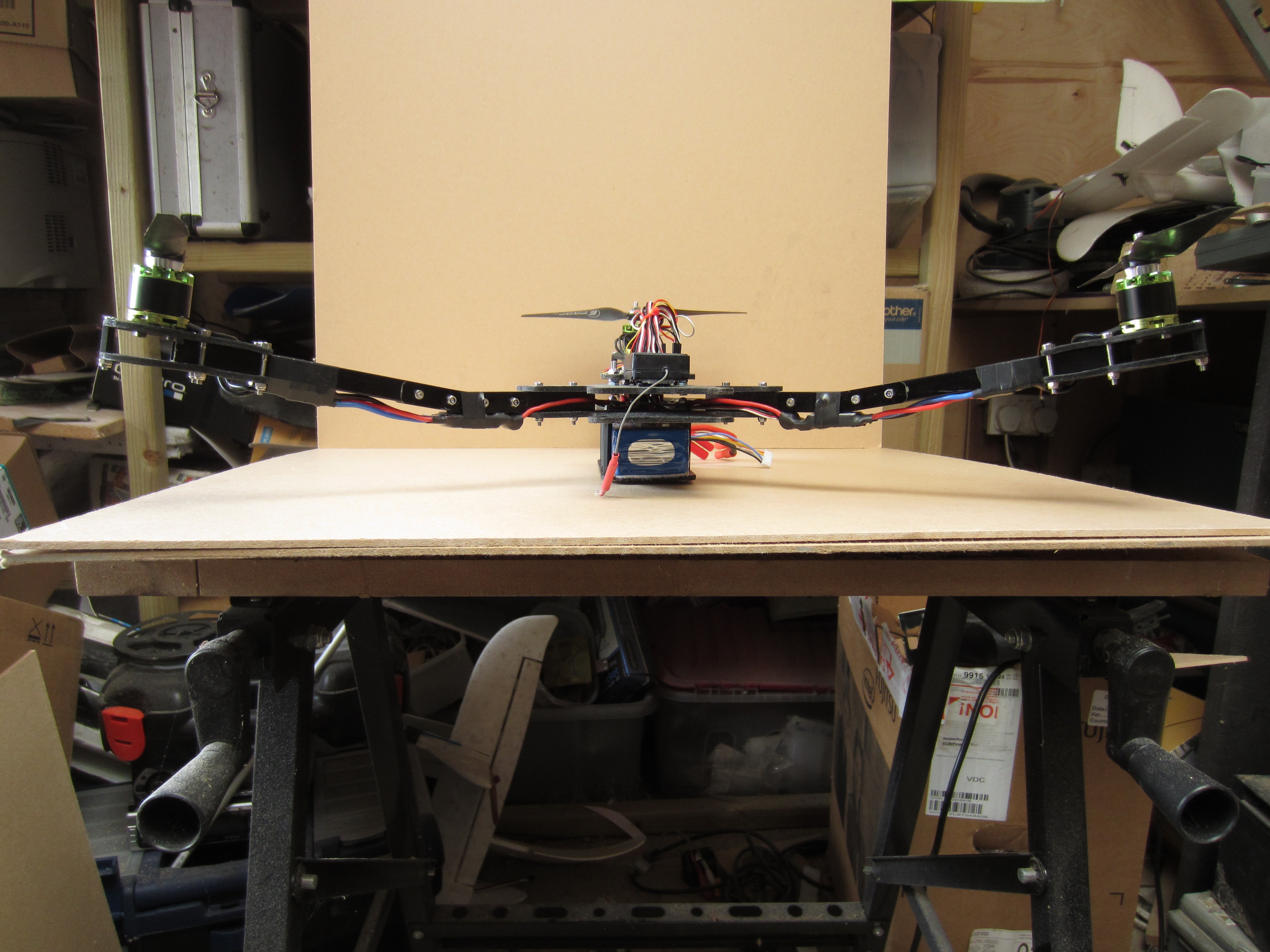

The main benefit to this material is obviously the cost.

MDF Sheet 3mm Thick x 912mm Length x 607mm Height= £3.49

I worked out that making the frame and motor mounts from one of these sheets would give me enough to build 3 copters... that £1.17 per copter!!

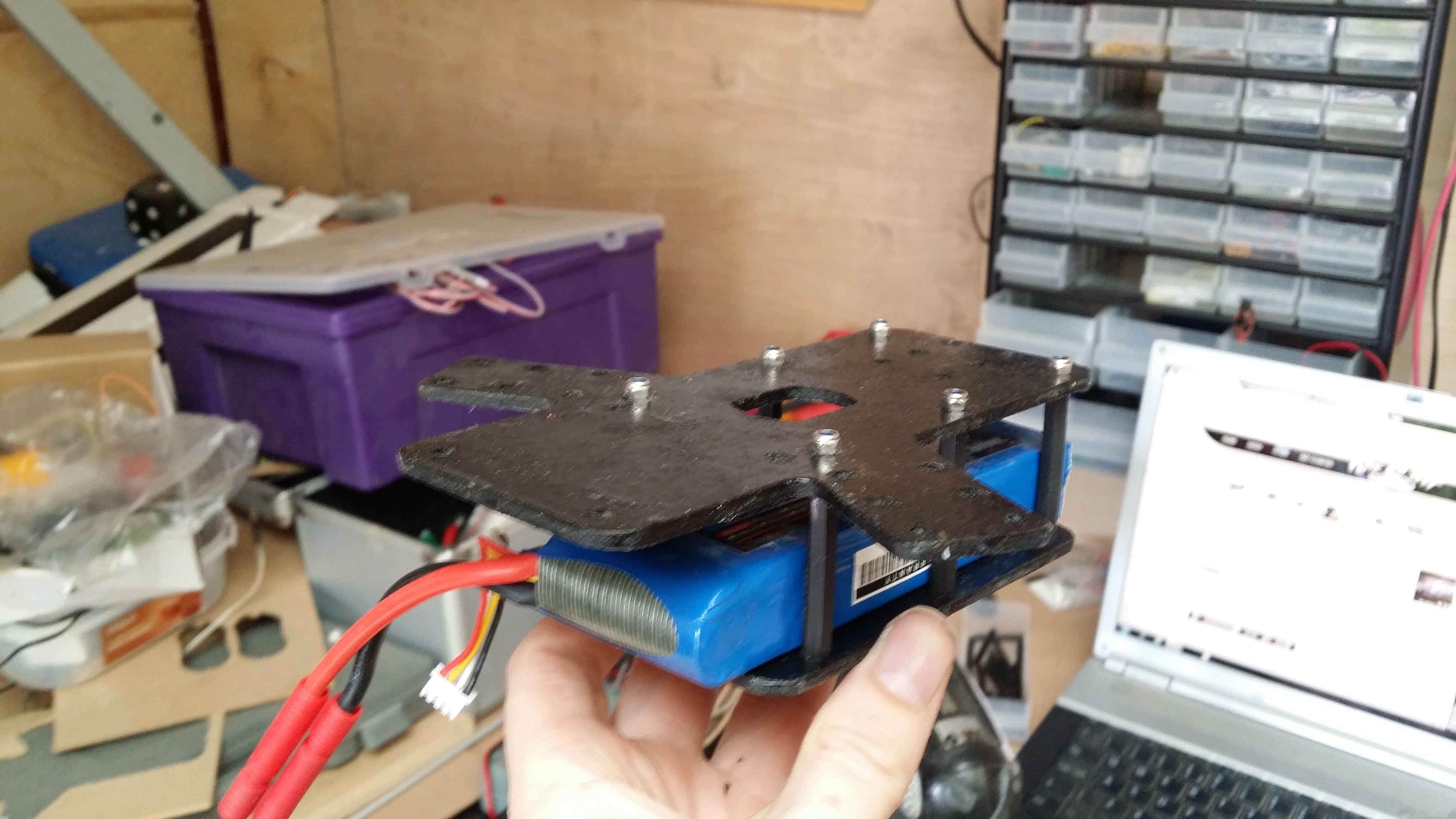

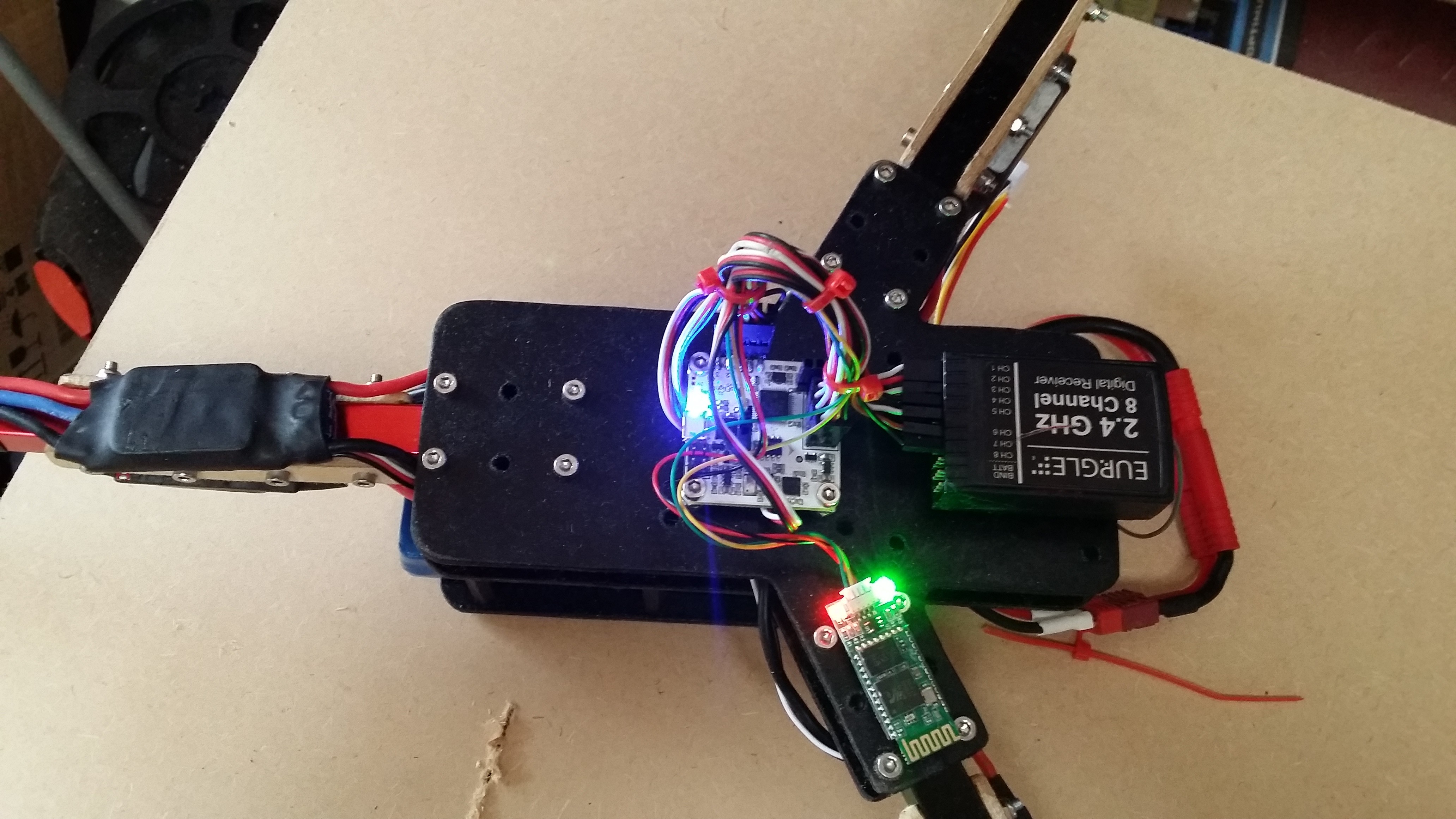

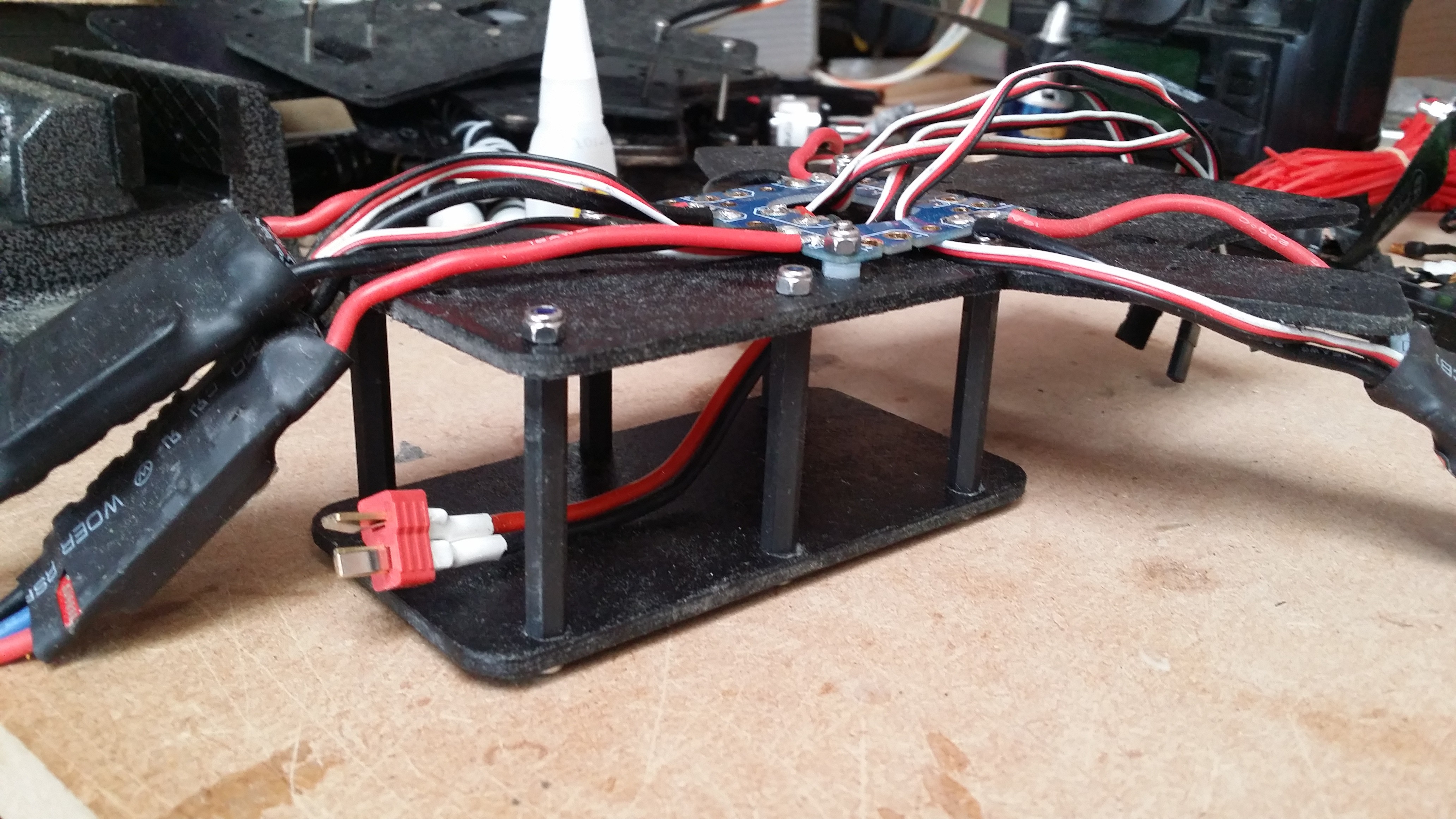

The second benefit is that the fibreboard does a fantastic job of absorbing vibrations (the bane of flight controllers everywhere!!!)

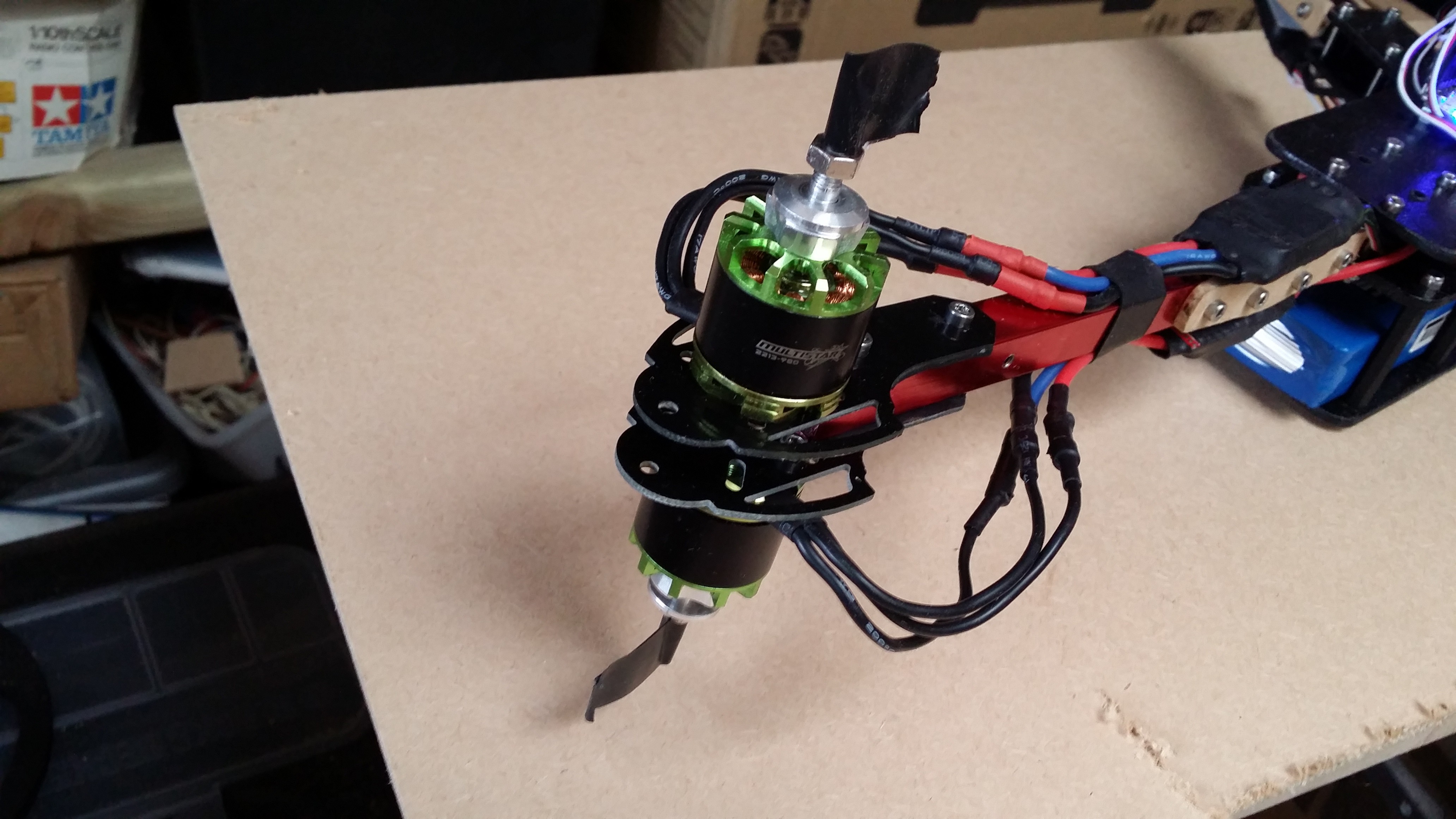

This was made very apparent as the first version of the copter had 1mm carbon fibre motor mounts and the vibrations were terrible, so much so at certain RPM's the copter was un-flyable. Now they are MDF the copter flies with no vibration issues at all.

KMD

KMD

Will F.

Will F.

Greg Duckworth

Greg Duckworth

Paul McClay

Paul McClay

Hi

Nice to meet you after viewing your profile i am Jacinda, from (jakarta) indonesia,

i have a project discussion with you please email me on: (jacinda.seiler@yahoo.com)