Sorry for the long bought of silence, between school and a mishap with the ordering department, I have just within the last week got all the mechanical bits required to mount the new treads. However there is still some mechanical bits that need to be finalized and some bugs to hammered out.

(sorry for the potato quality photos, took these on my phone before I left for spring break)

(sorry for the potato quality photos, took these on my phone before I left for spring break)

First on the list:

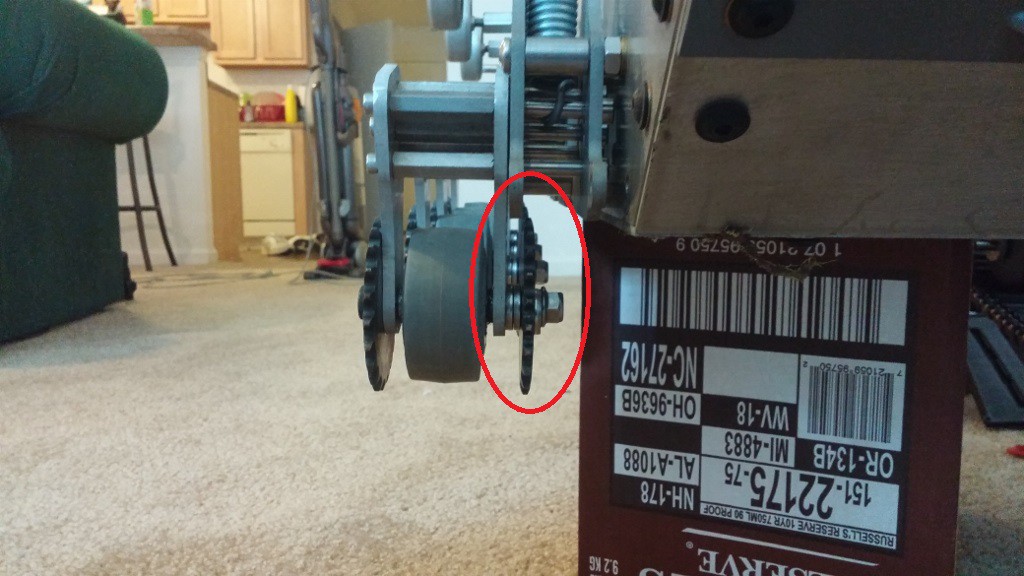

Sprockets on the wheel modules are creating some problems. Basically in order for the suspension system to work, the sprocket on the inside needs to be offset enough to avoid hitting parts of the suspension system

As you can see the sprockets had to be offset to avoid hitting the steel plate. However, The sprocket on the outside of the system has no washer now, and grinds the aluminium, and locks up.

You can see the marks on the wheel module above.

Basically I just need to play with spacing and spacer so that the sprockets can rotate without grinding but still be captive and rigid enough so the treads don't slide off. I'm thinking that laser cut acetal resin washers/spacers is probably the best bet. I've already used that technique to help reduce friction on the suspension system, as you can above and below.

The acetal resin dramatically helped with friction and binding, and combined with new oil-impregnated washer I hope will provide a longer service life before the washers wear out. I think doing something similar to the outside of the wheel module, combined with oil impregnated washers, would help the spacing of the sprockets as well as prevent the sprockets from binding and locking up the drive train.

I need to replace some parts of the drive train. Sadly, while taking apart drive train, I broke a standoff.

However overall I am very happy with the new tracks and cannot wait to get the system moving. And every single part I need to get the system function arrived in the mail before spring break. So hopefully I can get the platform moving before the 19th.

Software:

I've continued working on the monocular camera obstacle avoidance and I would say that overall it is going pretty well. Basically the last big challenge is getting rid of the latency due to the video frame buffer in OpenCv. Sadly the OpenCV video capture property CV_CAP_PROP_BUFFERSIZE isn't working with the Logitech C920 on the Odroid. Therefore another solution needs to be found to ensure the video frame being processed is as close to real time as possible.

But as you can see the algorithm works fantastically well on road surfaces

The next big step is to implement memory, and have the system save the histograms from previous frames and use those histograms to find obstacles in the current frame. This will remove the strong assumption that the area in the reference area (green box above) is free from obstacles and would allow the user to "train" the robot by manually driving the robot.

williamg42

williamg42

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.