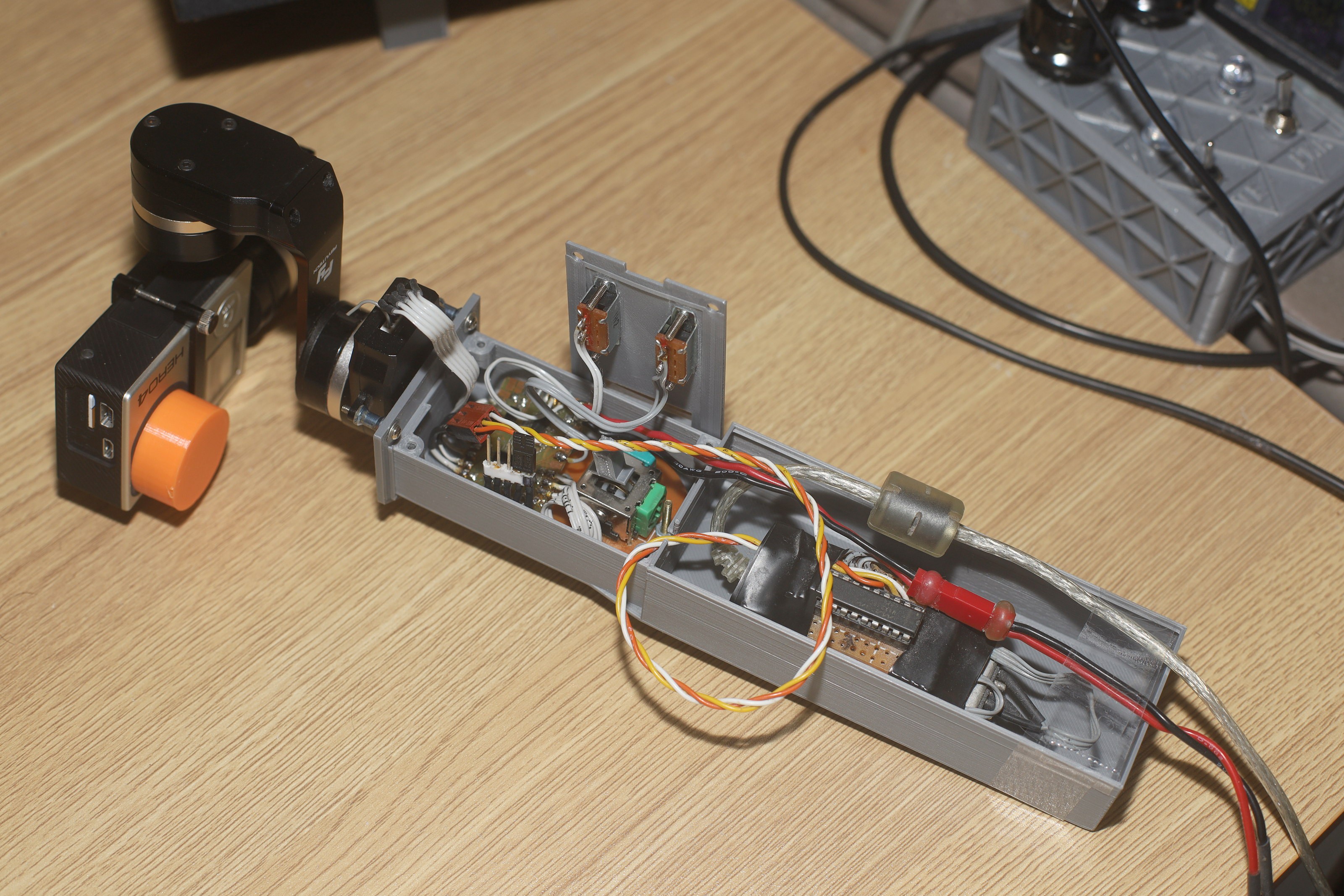

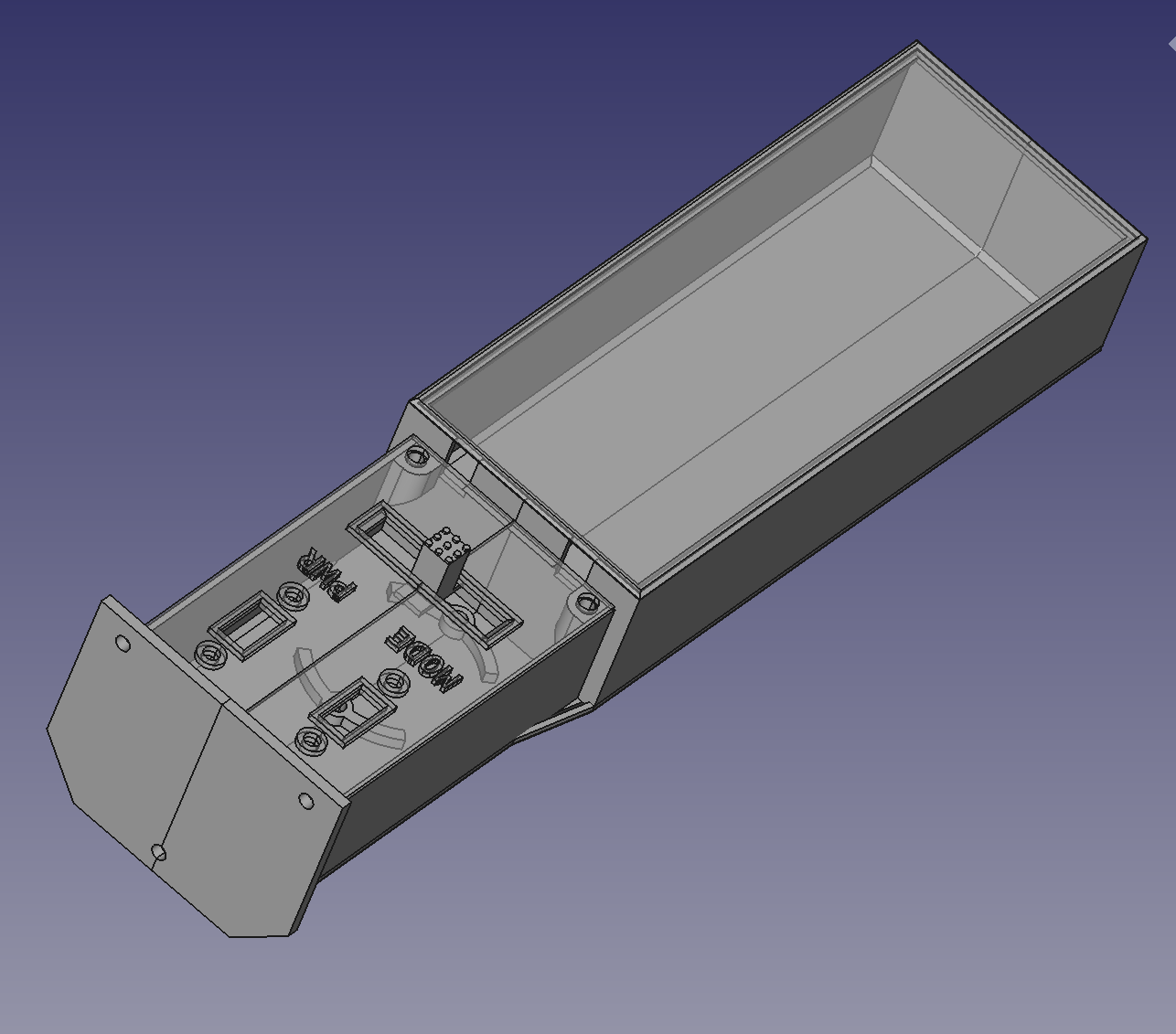

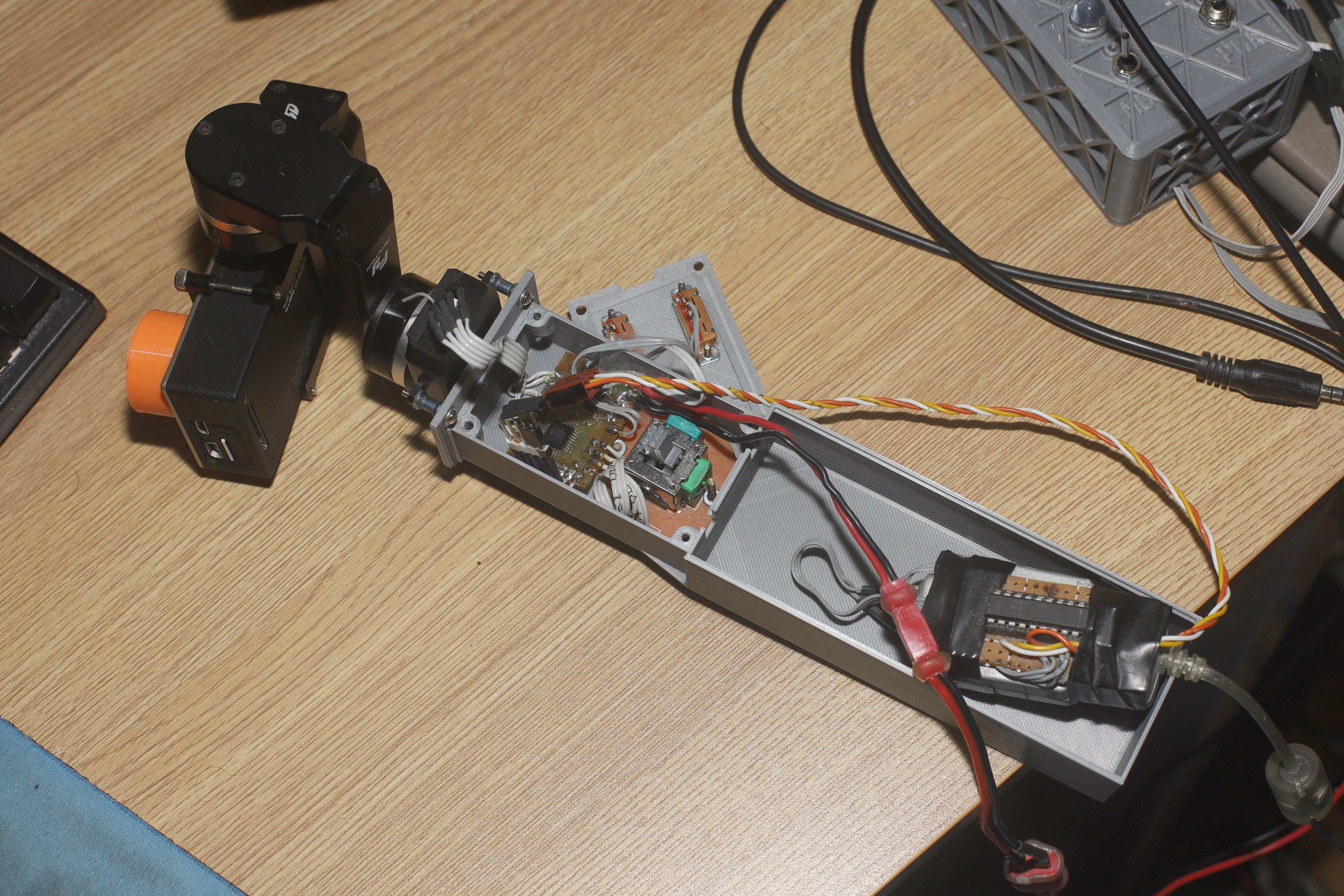

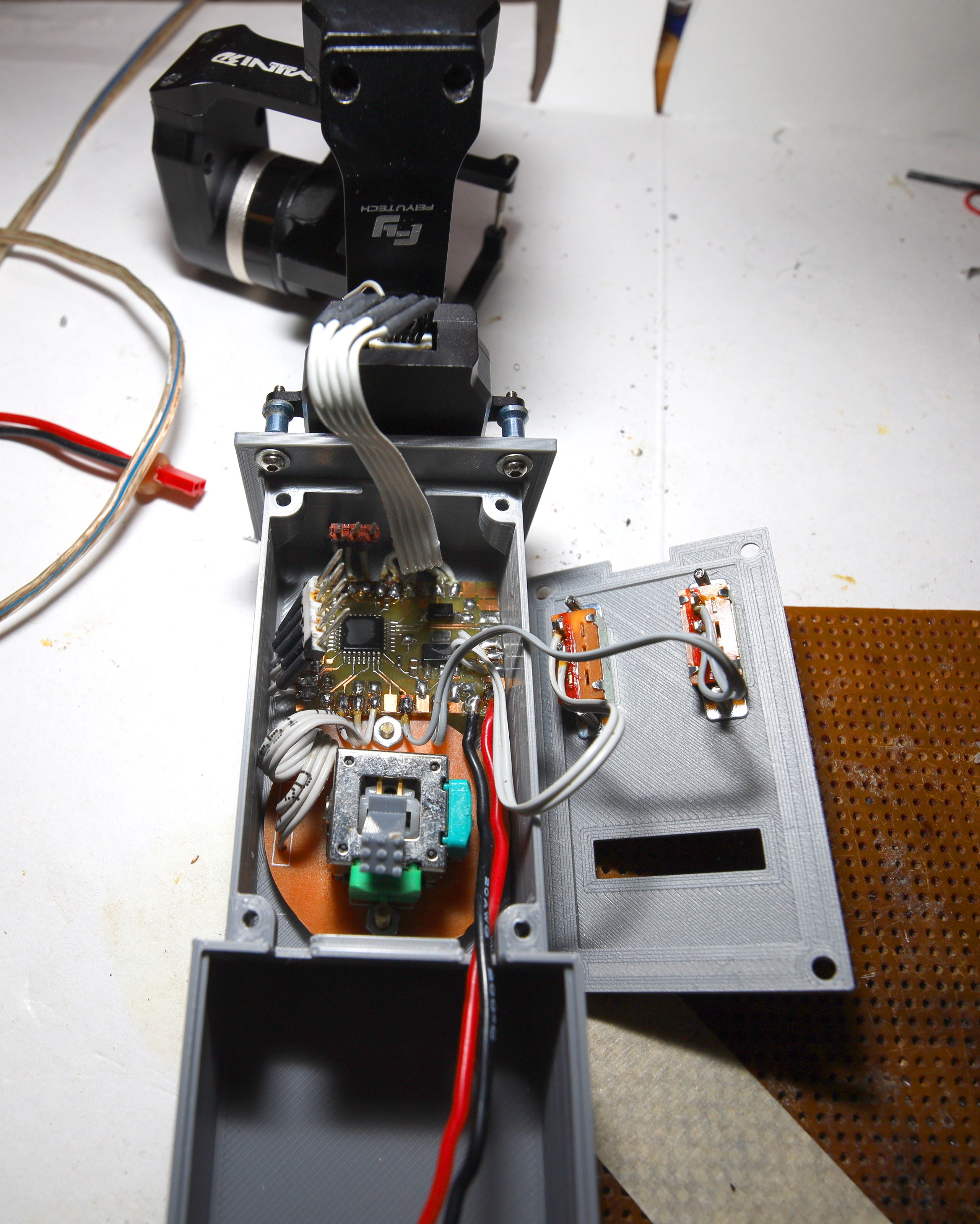

Miniature gimbal cams have abounded on quad copters in recent years, but have never appeared as standalone modules. We're still stuck with giant & expensive gimbals for phones & action cams. This continues to make junk like the Feiyu relevant.

While the custom firmware was as functional as needed in 2016, there is some desire to add highpass filtered terms to the feedback. It already did lowpass filtering to the gyro input, but never fully stabilized. It was good enough for 854x480 but horrible in 4k. Highpass filtered terms did so well for steering vehicles, it could buy some more pixels. This project is a motivational tool to try to improve the firmware.

After a short test, highpass filtering wasn't as good as straight derivatives. It took the same constants & 90% bandwidth.

lion mclionhead

lion mclionhead