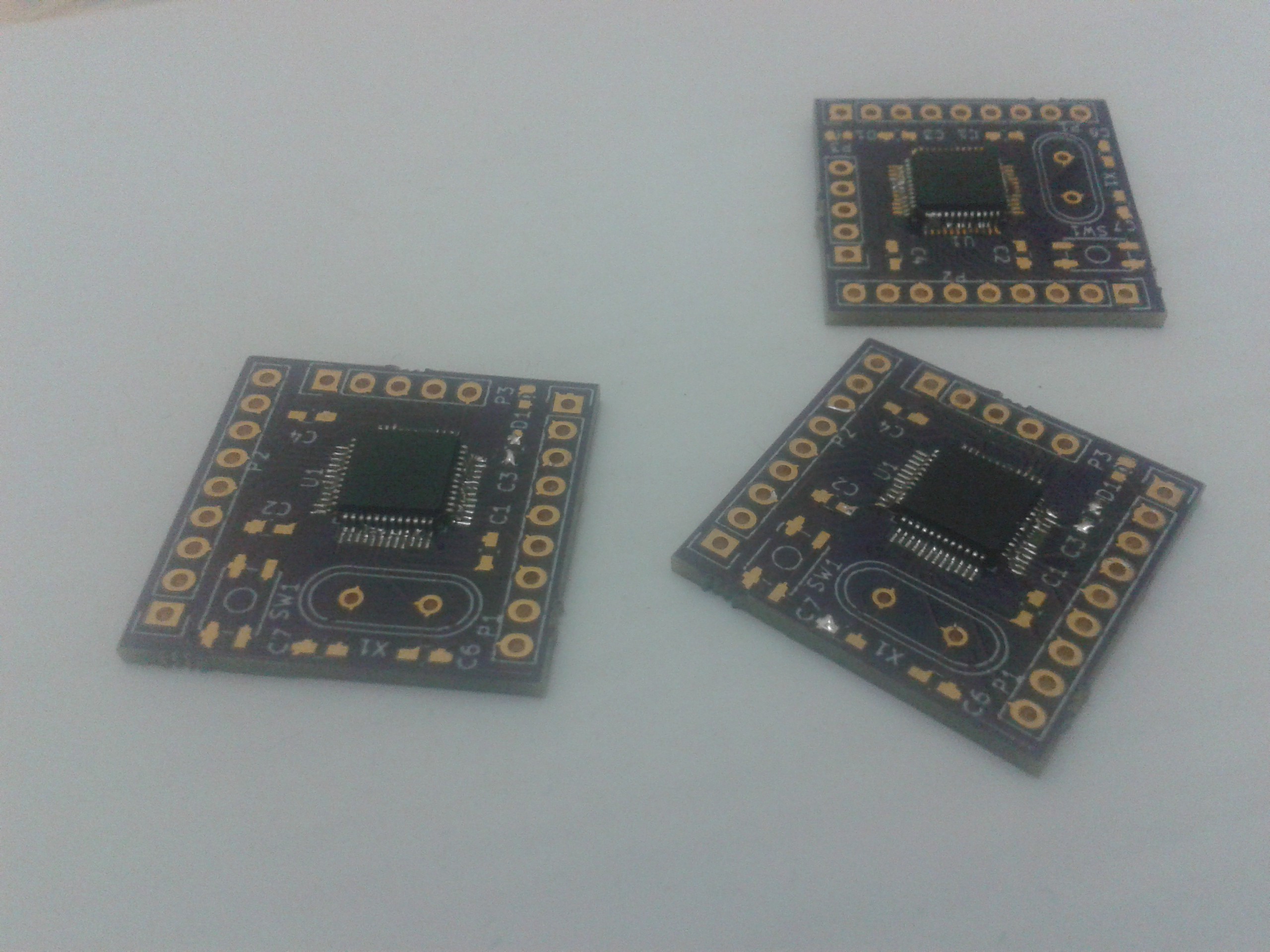

i finally got the ST chips I ordered from e-bay yesterday ( after over 40 days !!! ) .

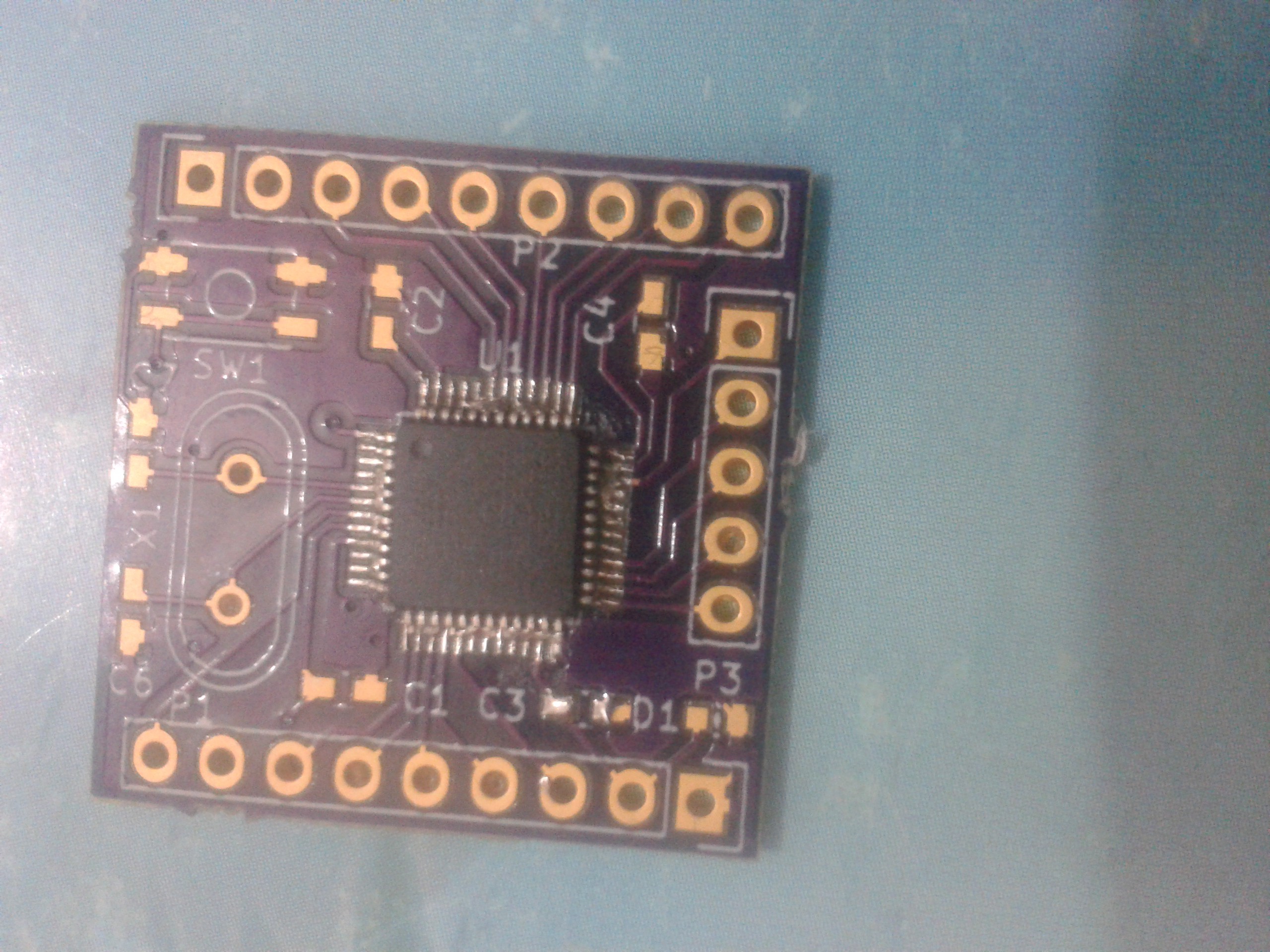

I went on and I tried to solder the LQFP48-package chips and indeed hand soldering these was a challenge. It's my first time as a hobbyist doing but I still mastered the courage to do it.

Results ??

Well it's not super clean and because I was unable to find solder wick in the near shop , I'm stuck with many bridges between the pins, at least untill the new stock is here.

Notes:

1) Solder wick is IMPORTANT.

2) Positing the chip was hard because some of the pins were out of place.

I will be working on a newer pcb version soon. I will also post updates about the current one , once i solder the rest of the stuff and I clean it.

Montassar

Montassar

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Please make sure to upload photographic or video proof of this project working by the next deadline (in about two days!)

Are you sure? yes | no

Sometimes I just heat it up and smash it on the table... I guess that is something I should not tell anyone :D

Are you sure? yes | no

I saw it on a blog a while ago and I know about that :p hhhhhh, It works sometimes , especially if you add a bulb of solder :D

Are you sure? yes | no

I do the same! Mostly when desoldering, though.

Are you sure? yes | no

That's the only thing (I know) that works to clean solder filled holes.

Are you sure? yes | no

You need to use some flux along with the wick, otherwise is hard to get it working. As long as you use flux you can de pretty well even with shielded cable thread or even 16awg flexible wire.

Are you sure? yes | no

Yeah I red about that somewhere but I had no luck with it actually , I used the flux (lots of)

Are you sure? yes | no

Try to moist the wick with rosin (solid flux) and put the wick between the soldering iron and the pads. If the wick absorbs much solder then cut it out and continue with a new piece. Keep practicing and you'll do it right all the times

Are you sure? yes | no

Personally, I've had pretty bad luck with solder-wick... I use a solder-sucker, instead. Usually that means adding *more* solder to the bridged-pins, then sucking it up. The nice thing is, once it's sucked-up, the pins themselves are usually soldered-down to the board well, so sometimes I intentionally just lay a fat blob over several pins then suck it all up.

The surface-tension thing, though... as Yann mentioned, I saw a video once (and have yet to actually need to solder another TQFP since) showing nothing more than setting the TQFP atop the pretinned (and heavily-fluxed) board, then heating it up with a heat-gun. Surface-tension aligns everything. Looks pretty easy, one quick motion with maybe a tiny bit of wicking in the end... Really easy compared to the dozen-or-so TQFPs I've soldered pin-by-pin over the years ;)

Are you sure? yes | no

That's actually similar to the way I reflow these days. The most tricky part is that the tinned surface is convex, so positioning the pins are a bit more tricky vs solder paste. You can tack down a couple of corner pins with the iron. (Solder paste and the stencils cost $$.)

I used to use my soldering iron press down on the pins one by one to reflow them. That's how I did all of the TQFP on my FPGA board. There was no solder bridges!

The solder wick I use is "SODER-WICK".

https://www.chemtronics.com/c-271-desoldering-braid-wick.aspx

Are you sure? yes | no

The biggest problem I can see here is not being able to control the amount of solder. Get the thinnest solder you can find as the regular ones are just too thick for this. I am using 0.016" (0.4mm) diameter before I switched to reflow. Flux helps a lot too.

Are you sure? yes | no

Indeed , however the smallest I was able to get my hands on was a 0.7 mm ( around 0.027" ) here. The local store lacks in many things so I guess I will order it online next time.

Flux helped me a lot, but alone it was not enough.

Are you sure? yes | no

Yes, flux is critical. Don't try to control the solder on each pin but let surface tension do its work :-) After a dozen of chips, it will be very easy.

Are you sure? yes | no

You can use a piece of wire as solder wick. Make sure you use a decent amount of flux.

Actually with some experience you can remove bridges without using solder wick as seen here:

https://youtu.be/6PB0u8irn-4?t=46s

. But you need an appropriate tip for this. I think using a solder wick is safer for beginners.

Are you sure? yes | no

I tried using a piece of wire but had no luck , moreover I was afraid of overheating the chip.

Just as you said , sticking with solder wick is a safer choice for now.

Thankx for commenting !

Are you sure? yes | no

What kind of tip are you using? A 2-3mm chisel tip is the best:

http://uk.farnell.com/weller/lt-a/tip-soldering-iron-chisel-1-6mm/dp/1323956 .

Are you sure? yes | no