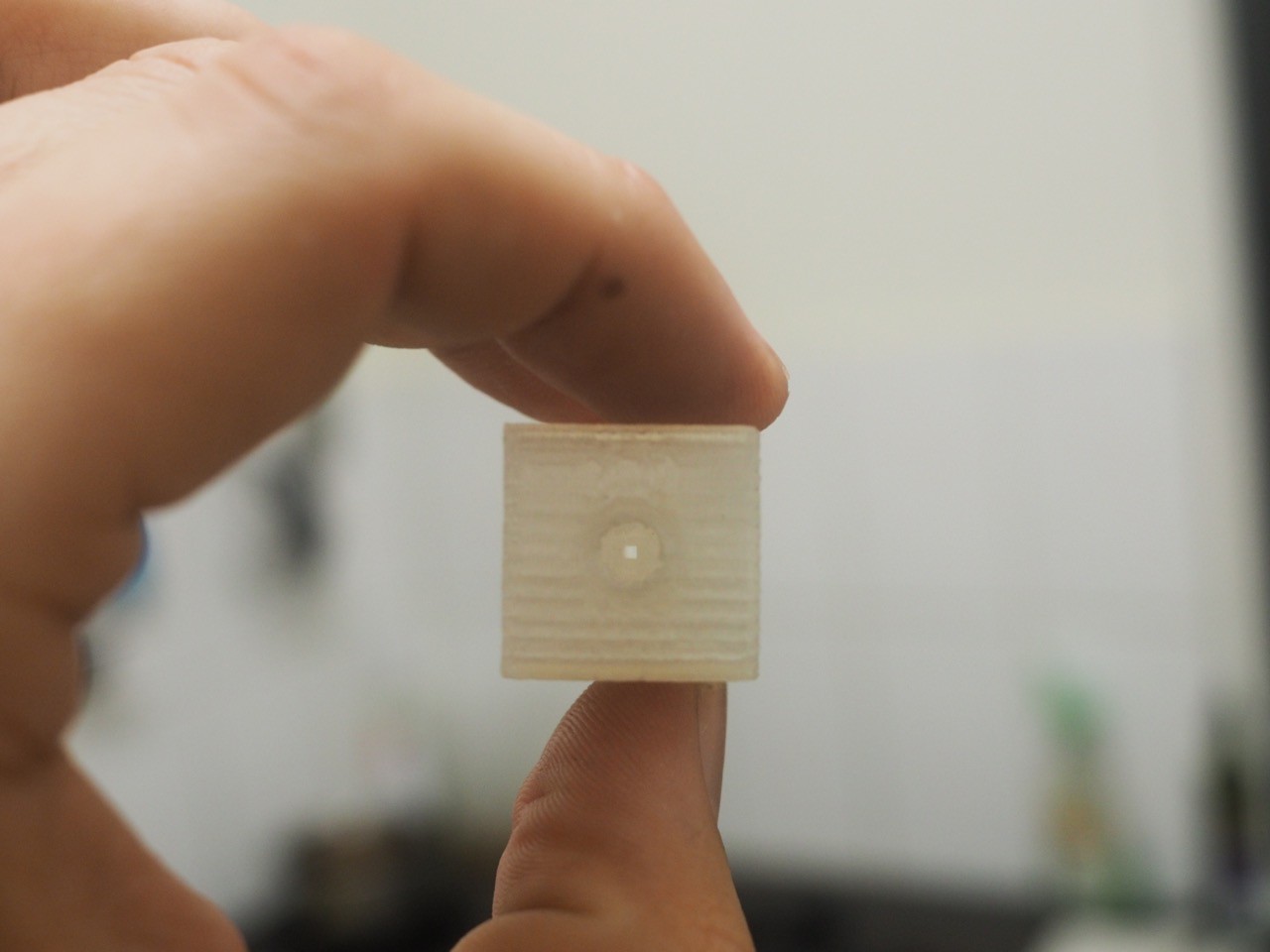

In order to connect our 1/16" tubing to the 365um OD capillary tube used for the separation process, we decided to 3D print a flow block rather than buying the ~$100s commercial units available.

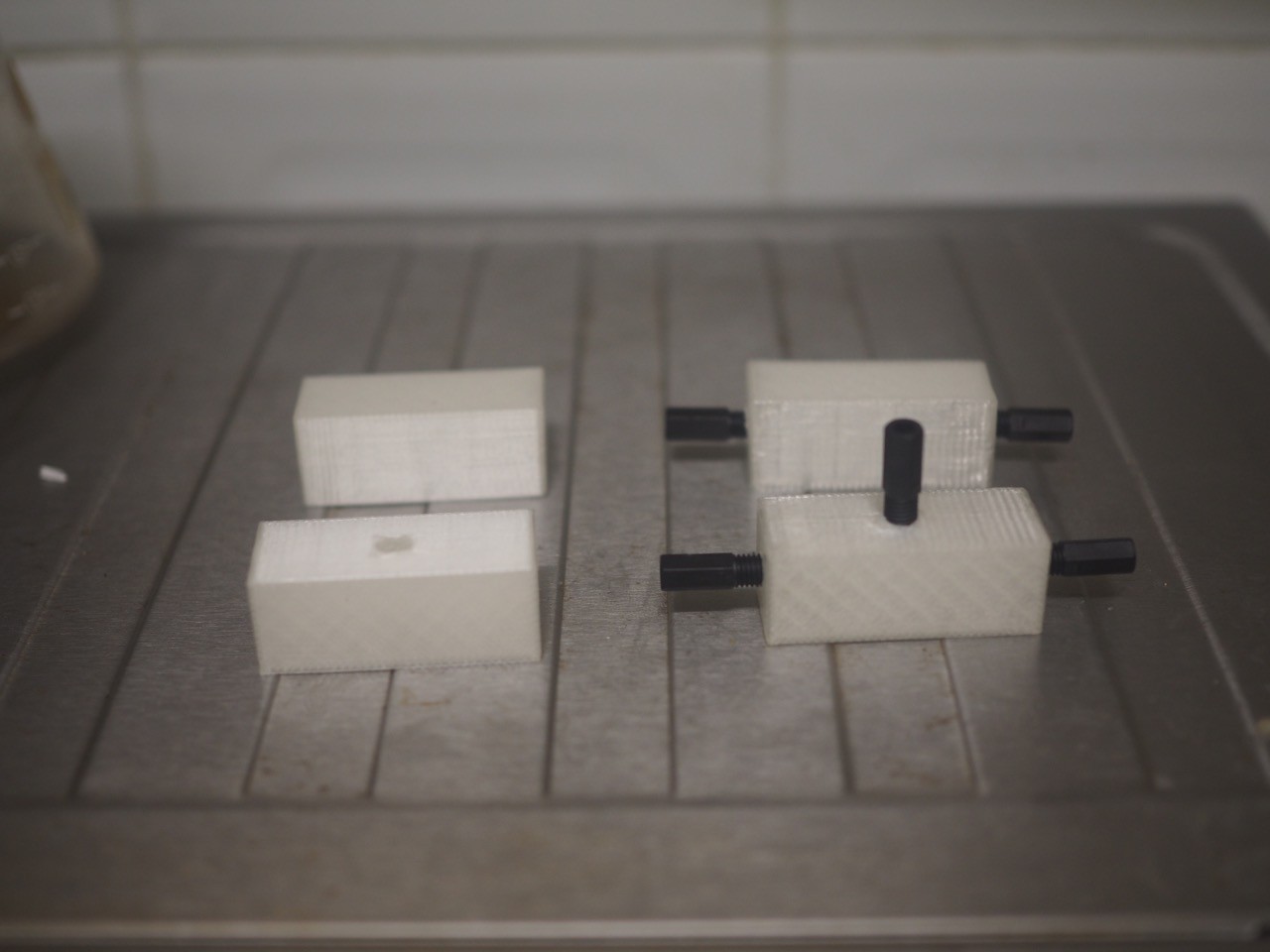

Each block serves as a connecting point to the capillary tubes through the use of a 1/4"-28 UNF nut. You can see the .STL files we used in our GitHub page LINK

The T-shaped block gives us a point where an electrode can serve as the ground for both capillaries, so we want it to screw in and sit in the flow path. The I-shaped block simply serves as a union between two 1/4"-28 UNF nuts.

Everything was printed on ABS as it is resistant to water and prevents biofilm formation. Acetone vapour treatment was used in an effort to better blend the printed layers and prevent leakage.

Each cylinder is 95% of the minor diameter of a 1/4"-28 UNF tap, which allowed us to easily tap the hole and test out the part by plugging in some tube.

Thanks to some kind souls on 3DHubs, we were able to get these produced overnight and delivered to our door for less than $20. Our fabricator was even able to remotely clear the bed and restart when we noticed an error in the diameter of the holes.

Taylor Wass

Taylor Wass

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.