Part 1:

Part 2:

Part 3:

Part 4:

Part 5:

Part 6:

Follow-up #1:

Follow-up #2:

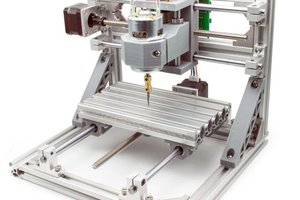

- work size: 160 x 160mm, Max. height: 25mm

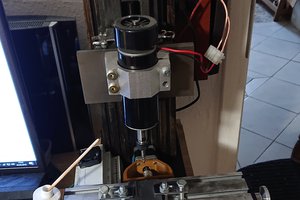

- Milling-tool: Proxxon, 20000rpm

- typical milling speed: 1-5mm/sec

- max. jogging speed: 10mm / sec

- milling materials (tried so far): PCB, plastic, wood

------------------------------

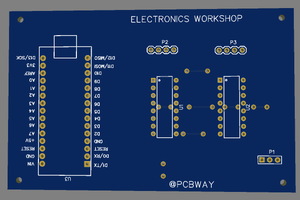

- Stepper drivers: 3 x Big Easy Driver

- Power: USB-Hub for the arduinos and all other 5V devices, 19V 3.5A laptop power supply for the stepper drivers

- Control: two Arduino UNO; both can control the stepper drivers. One runs GRBL and can process G-code commands from the computer. The other one runs my own software and is attached to the keypad and the LCD. This arduino gives a live feedback of the machine position via the LCD, even when the other arduino took over the control.

Hardware-ToDo: Connecting the GRBL-Arduino to the border switches (was not yet necessary) but will be needed for auto-leveling

- Manual control software:

- Moving in X/Y/Z direction: different speeds and different distances. The movement can be cancelled all times. Smallest moving step is 1/20mm.

- External mode: Live-feedback of the movement controls from the GRBL arduino, Internal mode: Manual control

- Homing/max loop, present table (moving table to foremost position), border-switch test

ToDo:

- Memorize position when system is switched off (no idea yet how to do that)

- G-code based Bed level test and auto-leveling

joekutz

joekutz

electronicsworkshops

electronicsworkshops

Li

Li

Morten Ydefeldt

Morten Ydefeldt

Hi I like the idea of making a CNC Mill as your project shows. I'm a retired toolmaker employed in the electronics industry. I'm trying to source the Stepper Motors, Big Easy Drivers and Arduino UNO but I am given various options for each part eg. Arduino Pro Mini 5V 16MHz,

3D Printer Big Easy Driver board v1.2 A4988 2A Phase Stepper Motor Driver Board etc Are the components you used anything special and if so could you please supply additional information. Many Thanks Chris