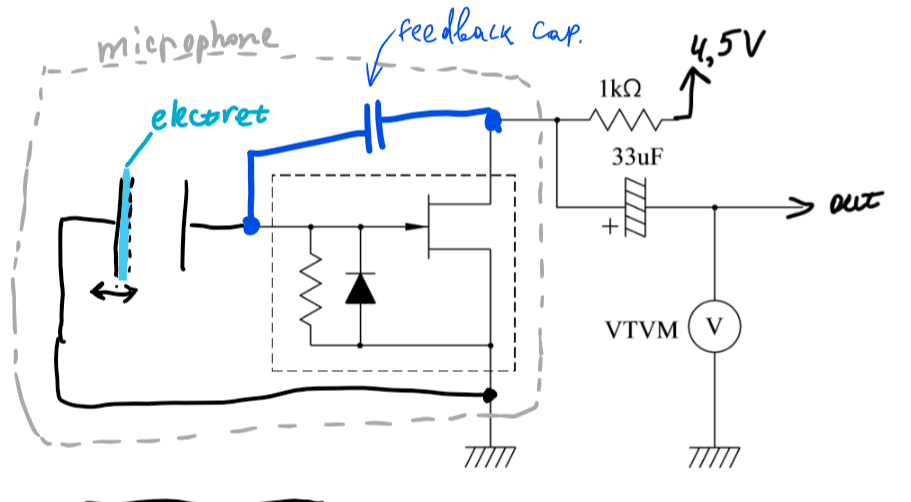

FAIL #1. feedback capacitor.

First attempt was to add a capacitor between jfet drain and gate. This should add feedback, thus reduce the gain of the jfet.

I was trying to do that by drilling holes in base pcb. (I didn't want to take the mic apart, because it's unclear how to put it back together after that, and if that may ruin the electret.)

First microphone I drilled had gate electrode available right behind the pcb, so I soldered a capacitor, and plugged the hole with photocurable epoxy. Unfortunately, I likely had blown the jfet while drilling, likely because my dremel was not earthed... the microphone was dead.

So I took another very similar looking one, drilled in same place, but there was no gate electrode. Then another one. I found where gate electrode was by illuminating the internals of the microphone with a laser, but when drilling it, I broke the thing, so another fail.

At this point, I ordered a few kinds of microphones, so that I have a bunch of similar ones to play with. So far, every microphone I had was unique, and its internal structure was quite unpredictable.

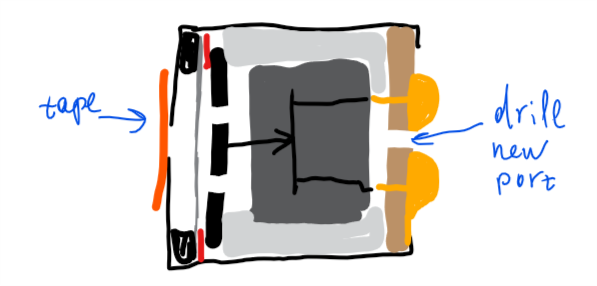

FAIL #2. changing internal volume.

If I reduce the internal volume of the microphone, I increase the stiffness of air inside, reducing the deflection of diaphragm. And I figured a really really easy way of doing it: plug the sound port with tape, and make a new sound port by drilling a hole in back PCB.

Done... and .... it's not enough! Still clips severely. =(

FAIL #3. depolarizing electret with temperature.

Easy, I just touched the microphone with soldering iron for half a minute or so. As the microphone cooled down, it was still waaay too sensitive, and I did notice substantial distortion at low SPL, so I might have melted the diaphragm, or something else was damaged.

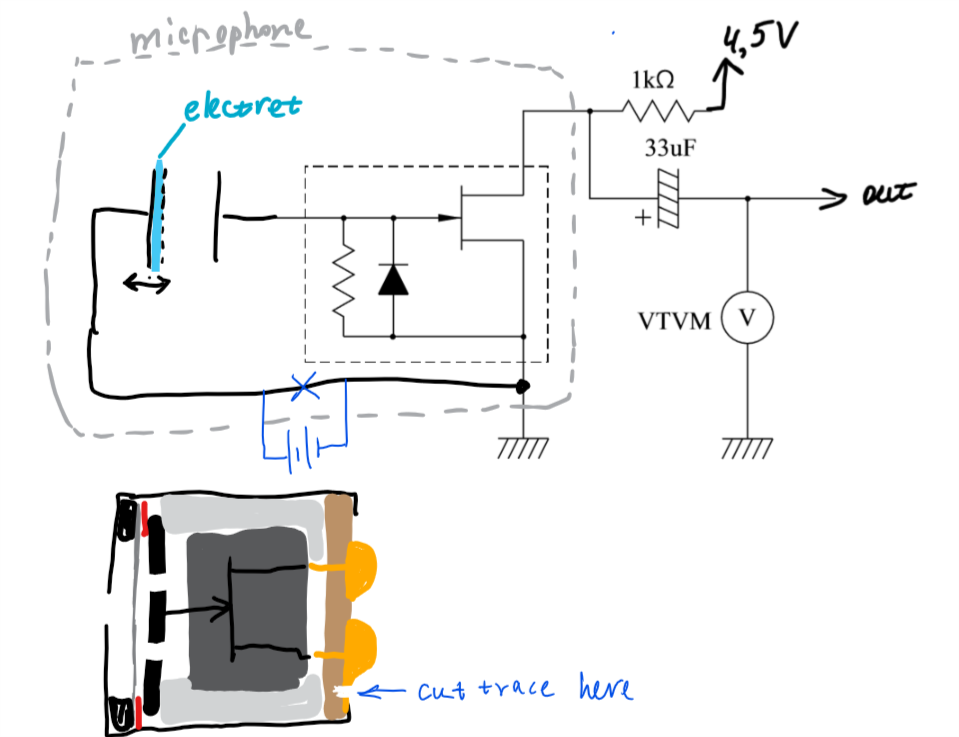

FAIL #4. Compensating electret with external voltage.

If I cut pcb traces that connect the case to one of the pads on the back PCB, I can then put a voltage source in series with microphone's sensing capacitor.

So I did it, and applied up to 100 V in either polarity. That was not enough deafen the microphone. It may be possible with higher voltage... but I don't want to mess with building a high voltage source just for that, and I need to compensate the field so that only about 1% of it remains, which requires a really stable voltage source, and precision tweaking with tongue at the right angle, and may drift with temperature, so that's not an option. Out of curiosity, it would still be interesting to check, how much voltage is embedded into the microphone thanks to the electret....

Other ideas that I didn't try:

* depolarize electret with x-rays

* with same approach as in FAIL 2, fill the cavity with something (say, oil) before taping it shut

* mechanical shielding from sound pressure. The difficulty is ensuring frequency response stays flat in 10-300 hz range, and has no phase lag...

* and of course, a lot more ways requiring a full teardown.

DeepSOIC

DeepSOIC

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Heat can depolarize the electret, so heating an electret microphone in a controlled way might desensitized it upon .

Also, some electret microphones are very picky regarding their soldering temperatures and duration just because of that: Too much heat, and the electret charges are lost.

Are you sure? yes | no

[this comment has been deleted]

Unlikely. Dynamic microphone has similar behavior to loudspeaker, it does not have flat frequency response in low frequencies. I absolutely need that flatness.

Are you sure? yes | no