I've designed SAB3T to be producible in low volumes with the tools that I have at my disposal. All of the parts that you can't go to Digikey or McMaster and buy can be fabricated by tools that I have access to. This is a proven process for me as I've had success selling my creations online. Thanks 6 Packer and Pivena!

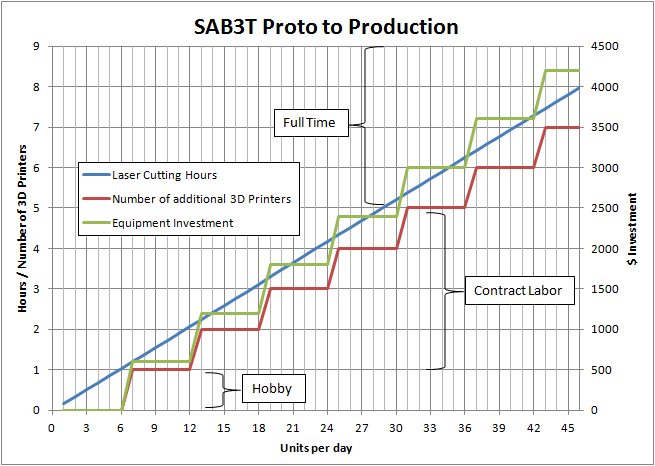

In the process of creating my prototypes of SAB3T I gathered data that I can use to make some production estimates.

Making Time for one SAB3T:

Laser cutting: 10.4 minutes

3D printing: 121 minutes

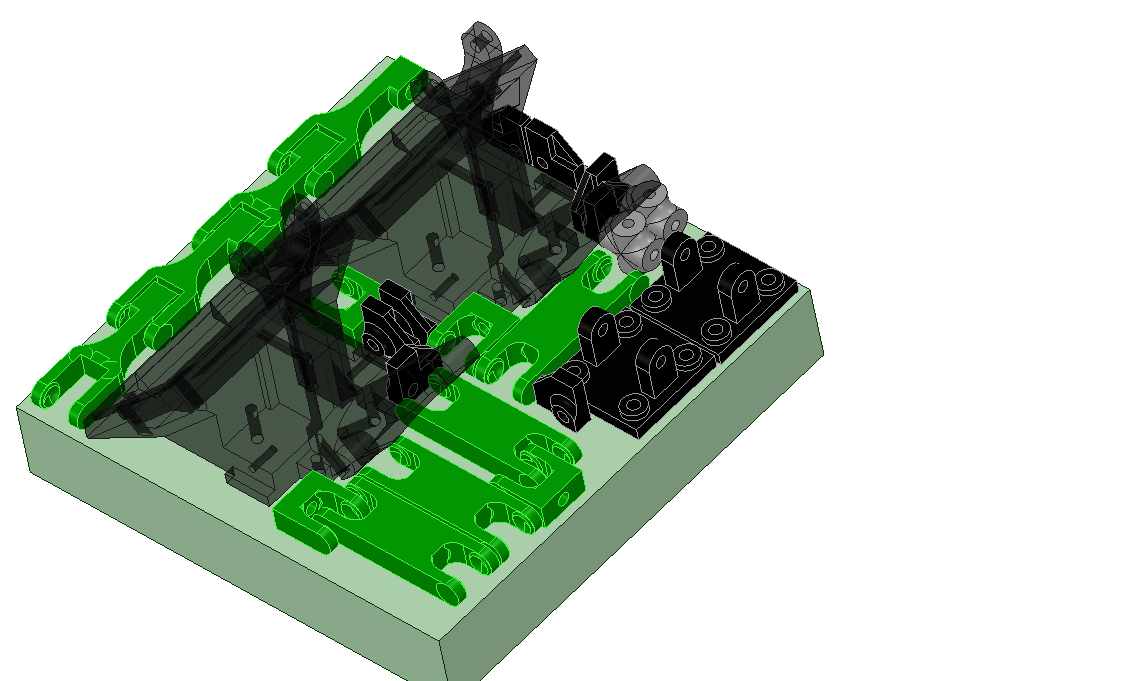

Obviously the slow thing is the 3D printing. In 2 hours I can 3D print 1 set of parts and lasercut 12 sets of parts. The upside though is that I could scale the number of 3D printers at my disposal. I use an UP! Mini currently. Below I've maxed out the parts that I can fit on the build plate, this would take about 4 hours to print and would make 2 sets of parts.

Using the above time estimates I've put together a projection of how this would scale as a product. Since I can run my 3D printer unattended these numbers assume that my printer is maxed out when I do 3 prints a day. At 4 hours a print this would mean starting a print before I leave for work, starting another print when I get home from work, and starting another print before I go to bed. So a fully utilized printer is printing for over 12 hours a day.

Hobby:

This assumes that I can spare 1 hour a day to SAB3T production. I spend 1 hour watching the laser cutter and packing sold orders. The 3D printer is restarted morning, afternoon and night. All together my equipment is able to produce 6 kits a day. Working 5 days a week I can create 30 kits a week. If I lose a day during the week I can make up on Saturday or Sunday.

Contract Labor:

I need to produce between 6 and 30 kits a day I will bring in contract labor. For every 6 additional kits per day another 3D printer needs to be added to my workbench. For example at 20 kits per day I need 3 additional printers working to keep up with orders

Full Time:

If SAB3T sustains a rate of between 30 and 46 kits per day I could make it a full time job. Running 8 hours a day I'll have my laser cutter maxed out, an army of 8 3D printers humming away, and a production capacity of 46 kits per day. I will have needed to invest a little over $4000 in the additional printers.

There are a lot of variables to consider here such as the speed / capacity of a different printer, profit per SAB3T, machine downtime for maintenance, etc. I won't try and graph everything, that would just be silly.

This exercise has shown me that I should be able to avoid the "pit of despair" https://www.sparkfun.com/news/909

Tim

Tim

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hey,

3D printing is good for a prototype, but I strongly recommend you find an alternative method for production. 3D printers are slow, inefficient, and extremely expensive on a per-part basis. It's not just the cost of the printers, it's time in setting up and repairing them, filament, failed prints, and worn out parts. Upload all of your models on Shapeways or 3D Hubs or something, and see what the real cost of your 3D printed parts are.

For small runs, your two best alternatives are to try and redesign the parts for your laser cutter (I haven't looked at your models so I don't know how viable that is), or resin cast them. Casting is reasonably simple and won't take you more than a few days to figure out, and has the advantage that if you redesign your parts to be easily castable, they will probably work well with injection moulding, too.

Anyway. Give it some thought. Production runs using 3D printers really really suck.

Are you sure? yes | no

Jarret,

Thanks for the input. I'll look into resin casting. Unfortunately all the printed parts are to complicated or unsuited for laser cutting. When I looked into resin casting before, it seemed that by volume resin parts were going to be more expensive than 3D printing them. Do you have a good cost effective resin to recommend?

I have been using my current printer for production parts with another design and have had very good luck with it. Once it is dialed in for the filament and design I'm producing I've found it to be quite high reliability.

Are you sure? yes | no