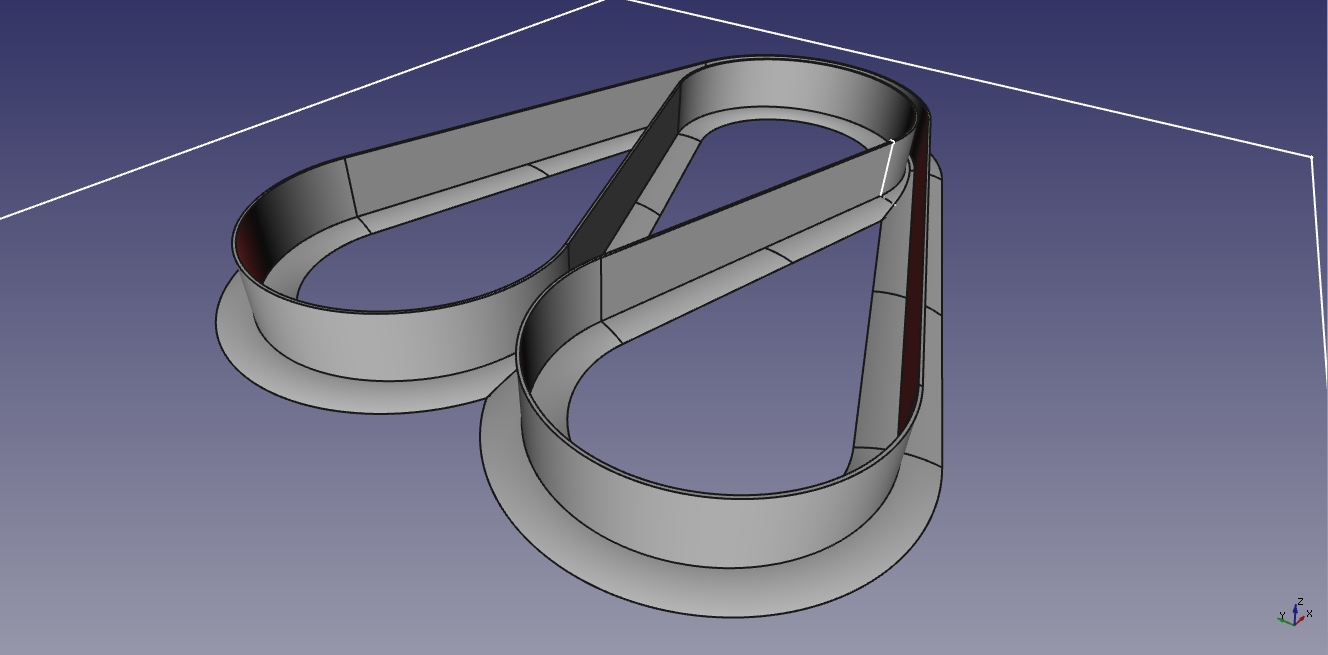

Test model:

It is a 0.4 mm thick ribbon, on a support shape to keep it from detaching from print bed. Modeled in FreeCAD.

It is a 0.4 mm thick ribbon, on a support shape to keep it from detaching from print bed. Modeled in FreeCAD.

6. SplineTravel+SeamConcealment. On this photo, it looks best; however, there is a lot of ooze on the internal side, which is reasonably easy to clean up.

5. SeamConcealment alone. There is a false seam (the visible stuff). It is the place where extruder lands onto the perimeter, but the actual extrusion starts later, in the melted-looking zone on the right, which is the true seam.

The false seam is actually very bad thing: it is an almost complete gap. It is caused by an ooze bump blocking the flow of plastic when the perimeter is completed later.

Overall, this is the best looking print, with no ooze at all, and a not very noticeable seam.

4. SplineTravel alone is also quite good actually, but it looks terrible on this picture. It is very clean on the inside. I is very much similar to 6, except good and bad sides are reversed.

3. Slic3r's wipe while retracting. I'm disappointed, it doesn't look like an improvement over 1 and 2

1 and 2. reference prints.

Update:

Print speed = 80 mm/s

Extrusion width = 0.4 mm (setting; actual ribbon thickness is 0.38 mm)

Ribbon width = 9.1 mm

Material = ABS

Extruder temperature = 240 °C

nozzle: 0.3 mm

Mechanical test results coming soon.

DeepSOIC

DeepSOIC

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.