To house all the electronics, I needed a plastic shell. Actually, several plastic shells; one for the high voltage oil tank, one to hold an x-ray tube, one to hold aluminum filters, one to hold the high voltage oil tank, a handle to hold everything... it goes on!

To design these, I broke out my favorite CAD suite: Autodesk Inventor. I also broke out the caffeine, and spent some 14 days staring into inventor, to design the following *injection moldable :D* parts

-

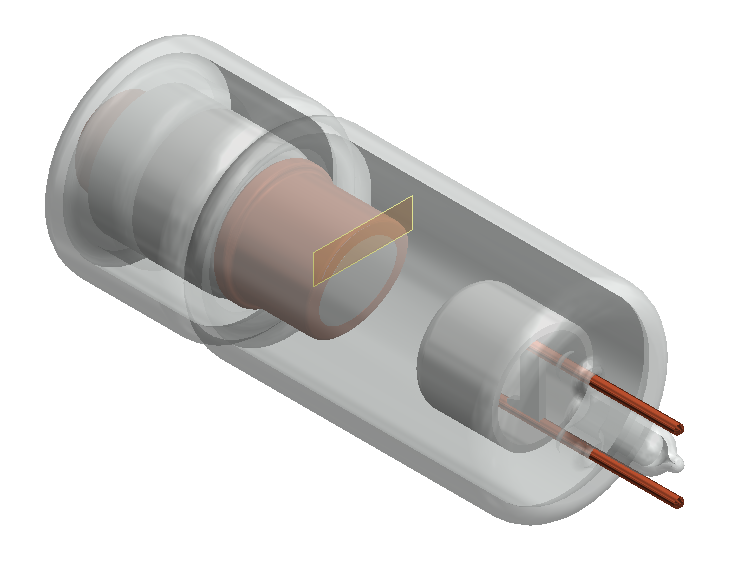

A model of my chosen x-ray tube:

-

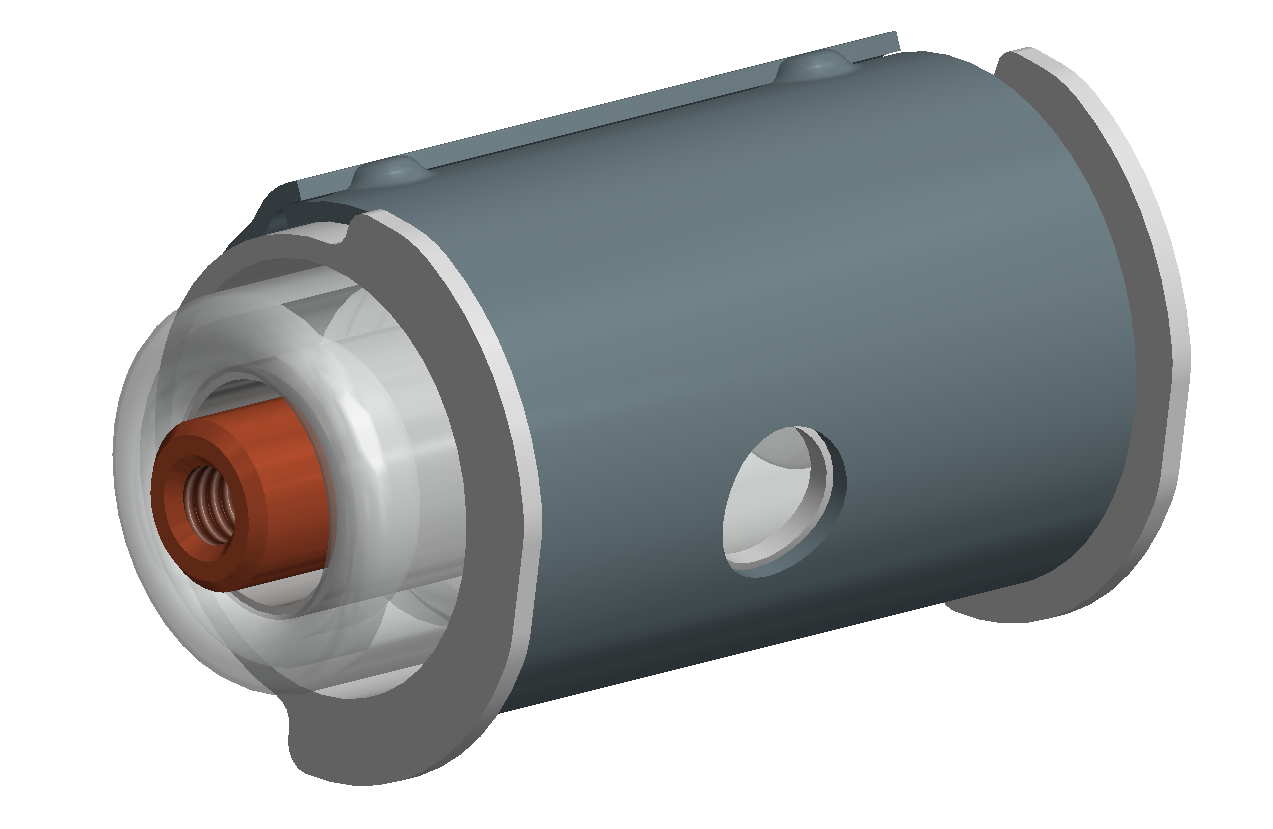

A shell to hold the tube, and a lead jacket around it:

-

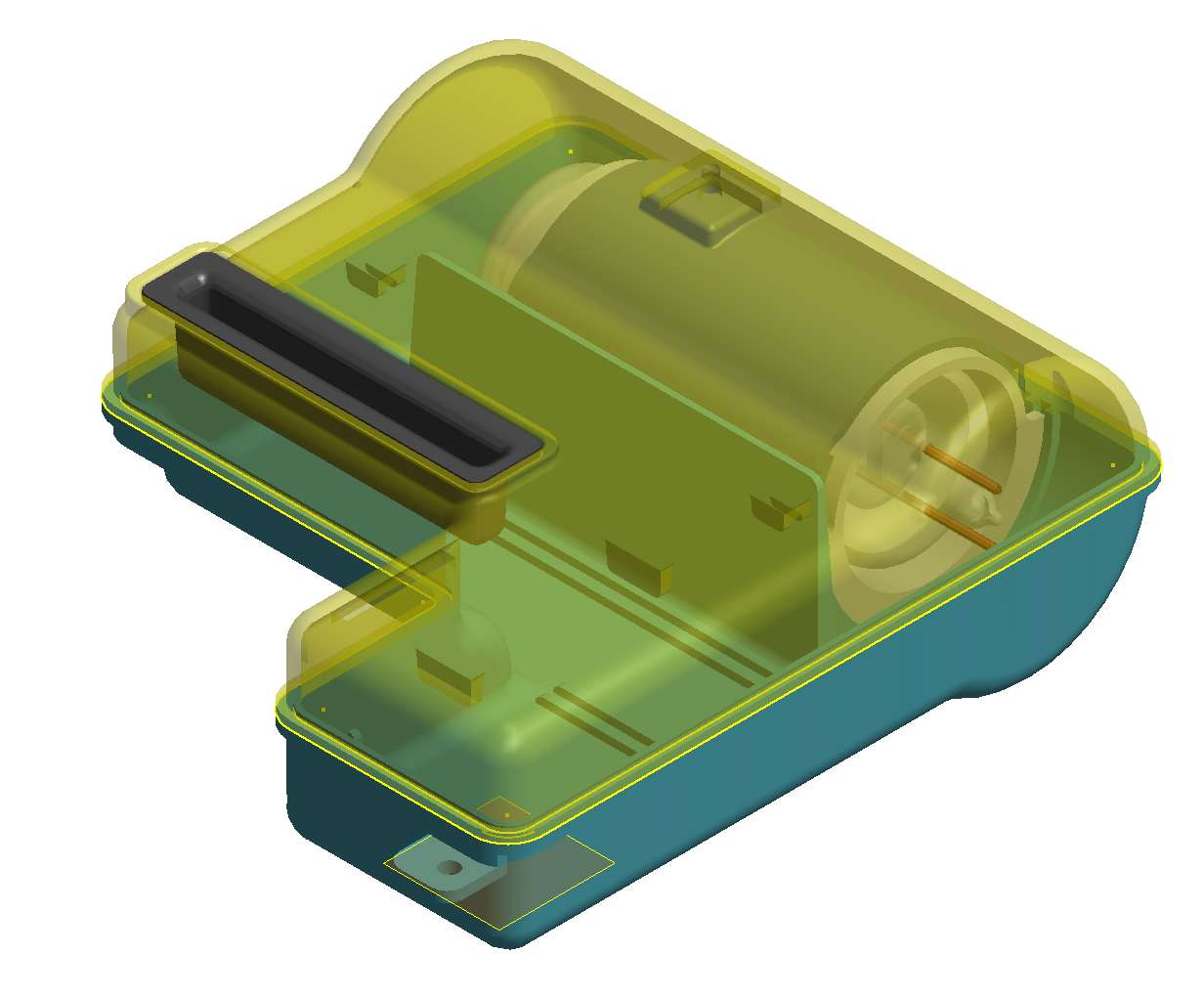

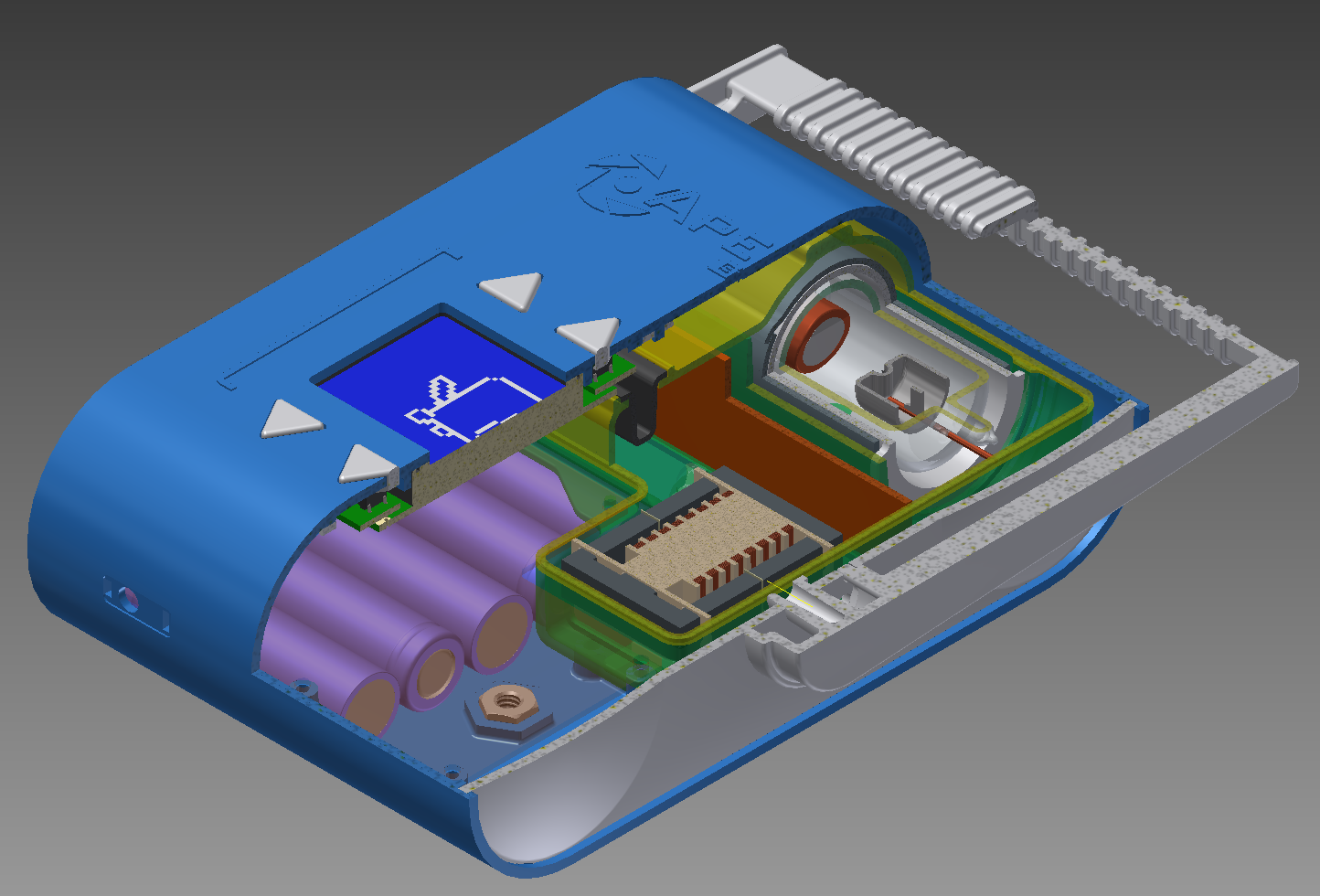

An oil tank, to hold the tube, the shell, and its wrapping:

-

A lid for the oil tank, and a rubber chamber to allow for thermal expansion:

-

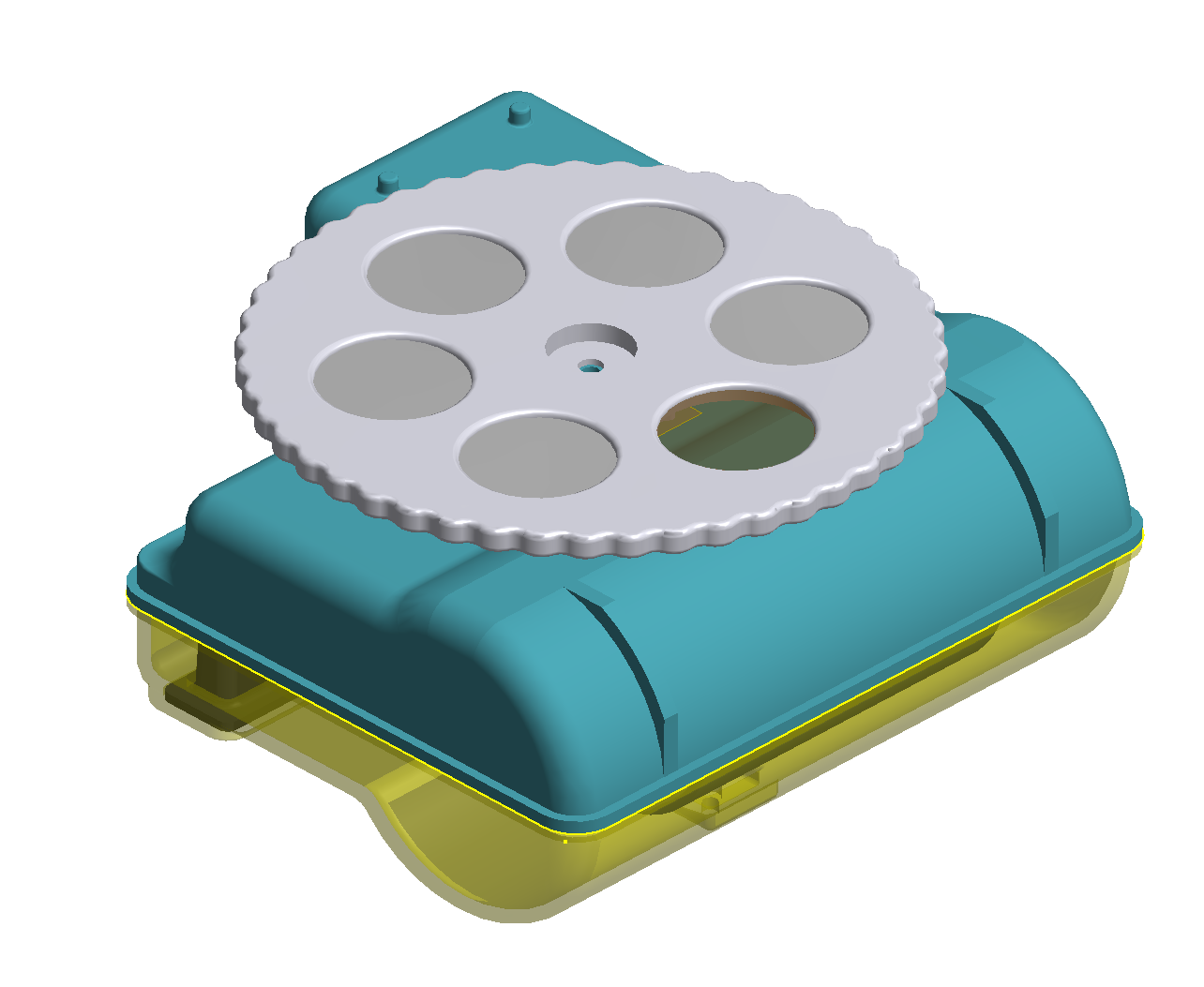

Aluminum filters of different thicknesses, and a disk to hold them in place:

-

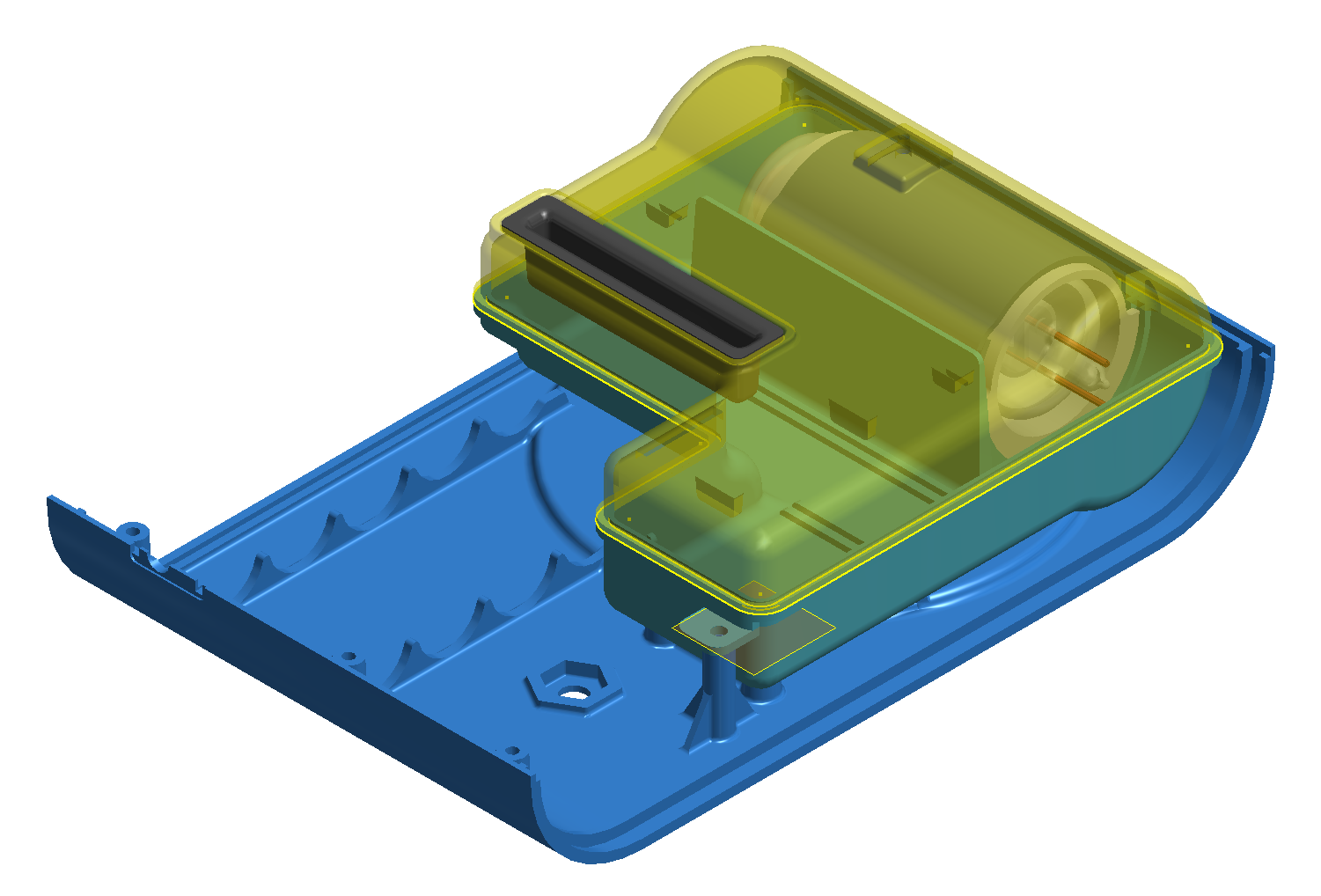

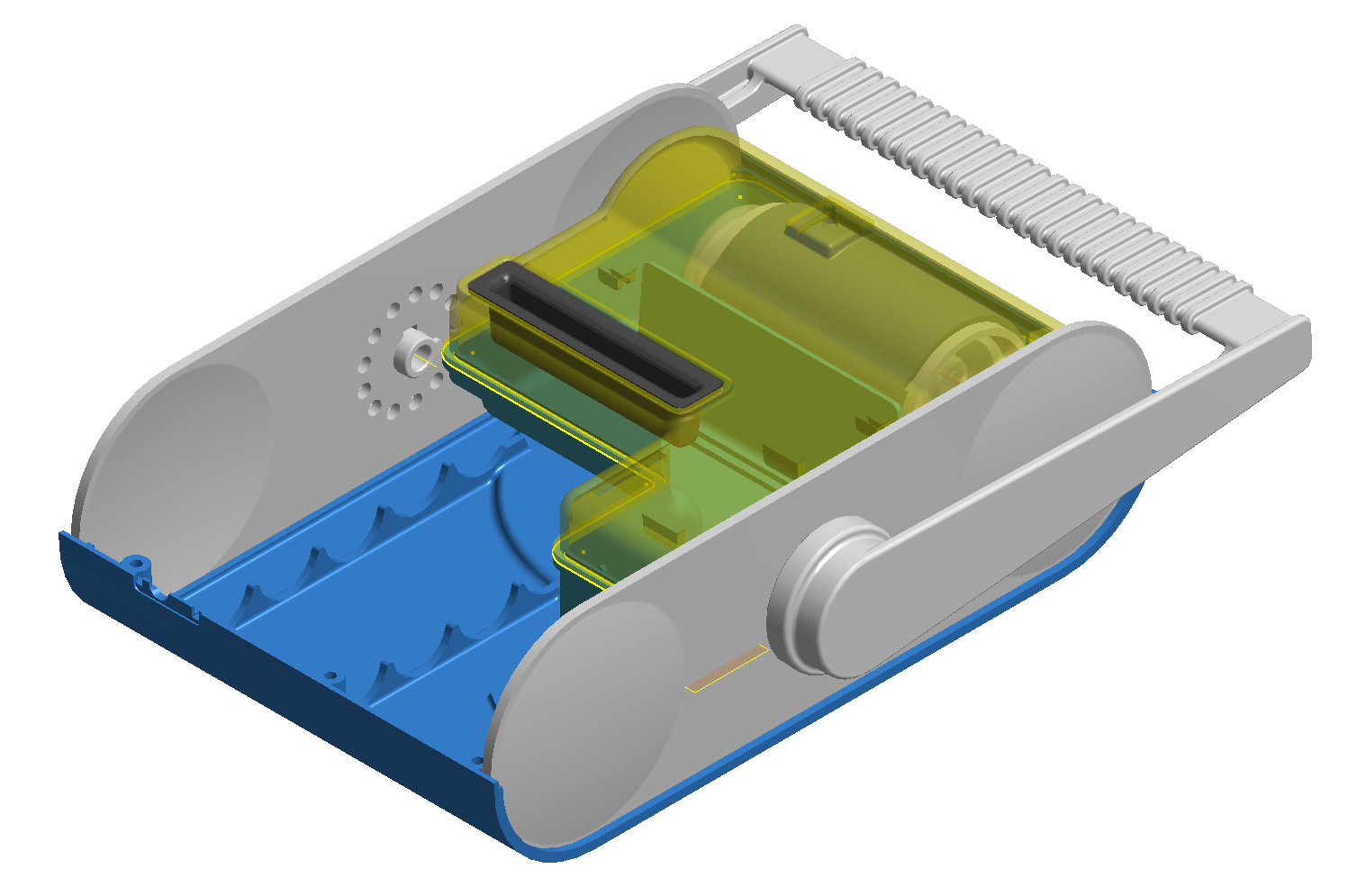

A shell to hold the oil tank, and other parts:

-

Sides, and a handle to allow for easy carrying.

-

An LCD, and PCBs to hold components, buttons, and the voltage multiplier:

-

And finally, a top shell and a rubber flippity-flap to cover the power receptacle:

______ _ ______ _

| ___ \ | | | ___ (_)

| |_/ / __ _ __| | __ _ | |_/ /_ _ __ __ _

| ___ \/ _` |/ _` |/ _` | | ___ \ | '_ \ / _` |

| |_/ / (_| | (_| | (_| | | |_/ / | | | | (_| |

\____/ \__,_|\__,_|\__,_| \____/|_|_| |_|\__, |

__/ |

|___/

Then came the 3D printing, the long, torturous 3D printing.

Some people have trouble with parts peeling off, but often, I have the exact opposite problem. x_x

Adam Munich

Adam Munich

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.