At the end of November, I just about had all the electronics designed and working reliably. My code had been written, it seemed to work well, and overall things were looking bright. However, it was now time to assemble everything I neglected, including the high voltage oil tank.

Why an oil tank?

To run an x-ray tube, you need a very substantial voltage: anywhere from 60 to 80 kiloVolts is not uncommon! At these voltages air is unfortunately a pretty poor insulator, and will break down readily to the detriment of your high voltage components. Oil on the other hand, tends to be a pretty good insulator.

At first, I tried taking baby oil from the local grocer, and pumping it down under vacuum to drive out all of the water.

-

-

For some time this proved to be sufficient, however, after a while I noticed some sparks in the (leaky) oil tank. Clearly, I needed real dielectric oil!

Unfortunately, just going out and buying dielectric oil isn't the easiest thing to do. It's sold only in 55 gallon drums, and, to buy any less of it means you're going to need a friend with such a drum. That was not something I had, but, after about 20 phone calls to companies around the bay area, I found a motor repair shop which was willing to let me fill up a jar of Shell Diala AX.

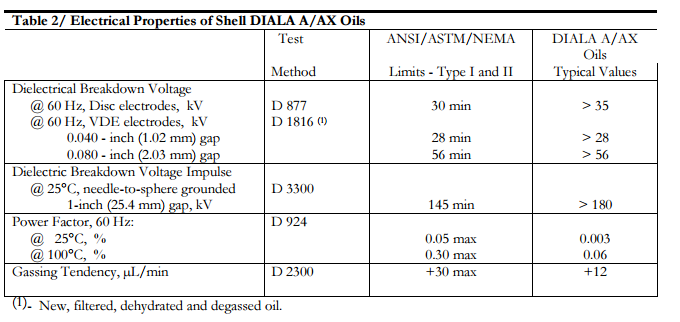

The specs of this oil are amazing!

It's not often you see "water" measured in units of PPM.

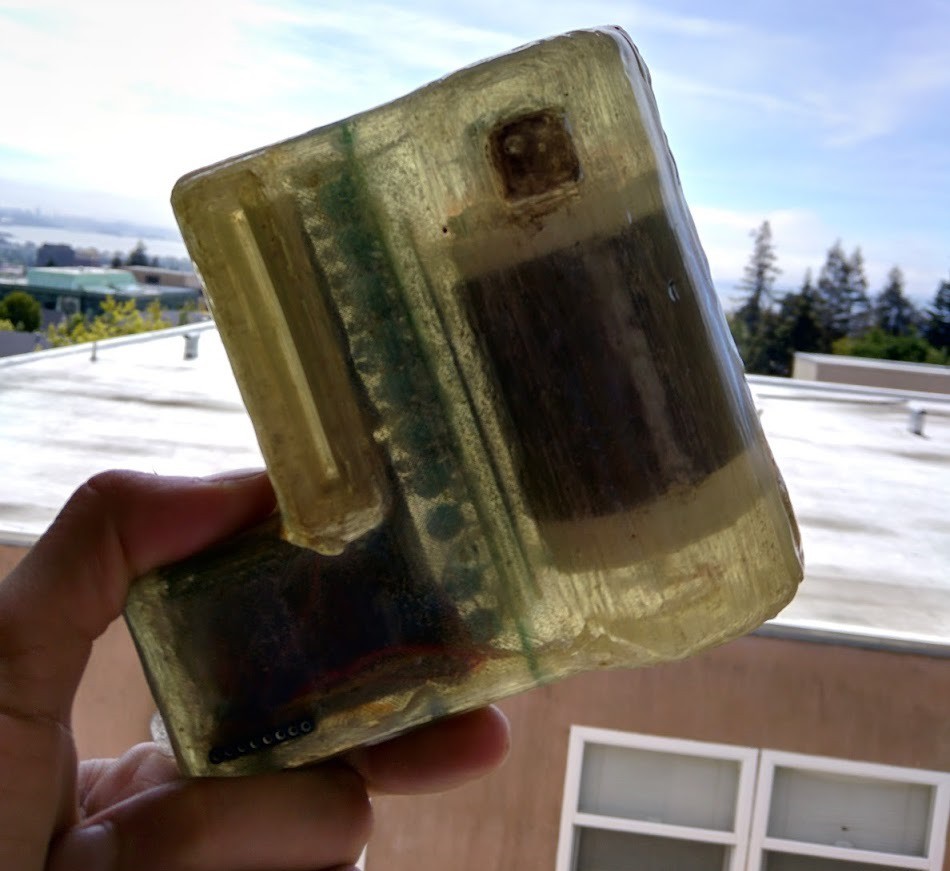

Using this oil solved the sparking issue, and covering the 3D printed oil tank in several layers of epoxy fixed the leaks.

-

In a way that's quite pretty, if a bit lumpy.

Following this, I had my first real x-ray beams. Interestingly enough, on a phosphor screen, they were bright enough to see in a semi-lit room with the unaided eye.

-

-

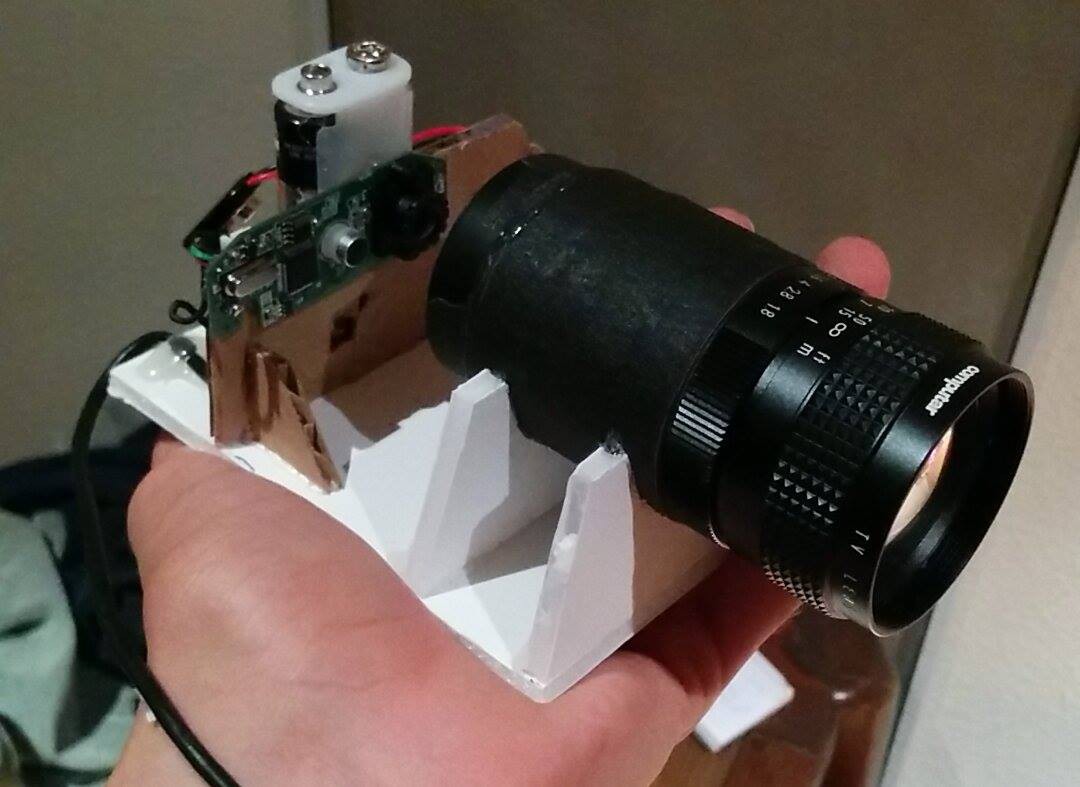

To capture x-ray images, I attached a lens to an image intensifying tube, and, placed that in front of a Logitech webcam. With a mirror, this assembly could view the image from a phosphor screen without picking up too much noise.

-

-

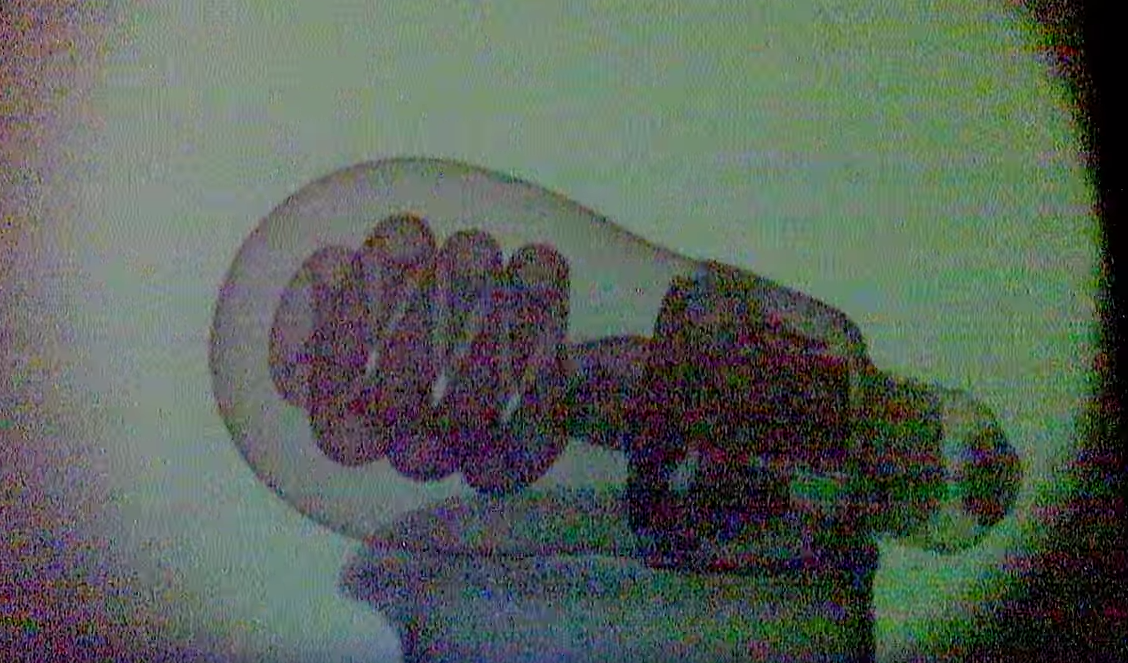

And, how did it turn out?

-

-

A little noisy, but clearly, working!

Somewhat.

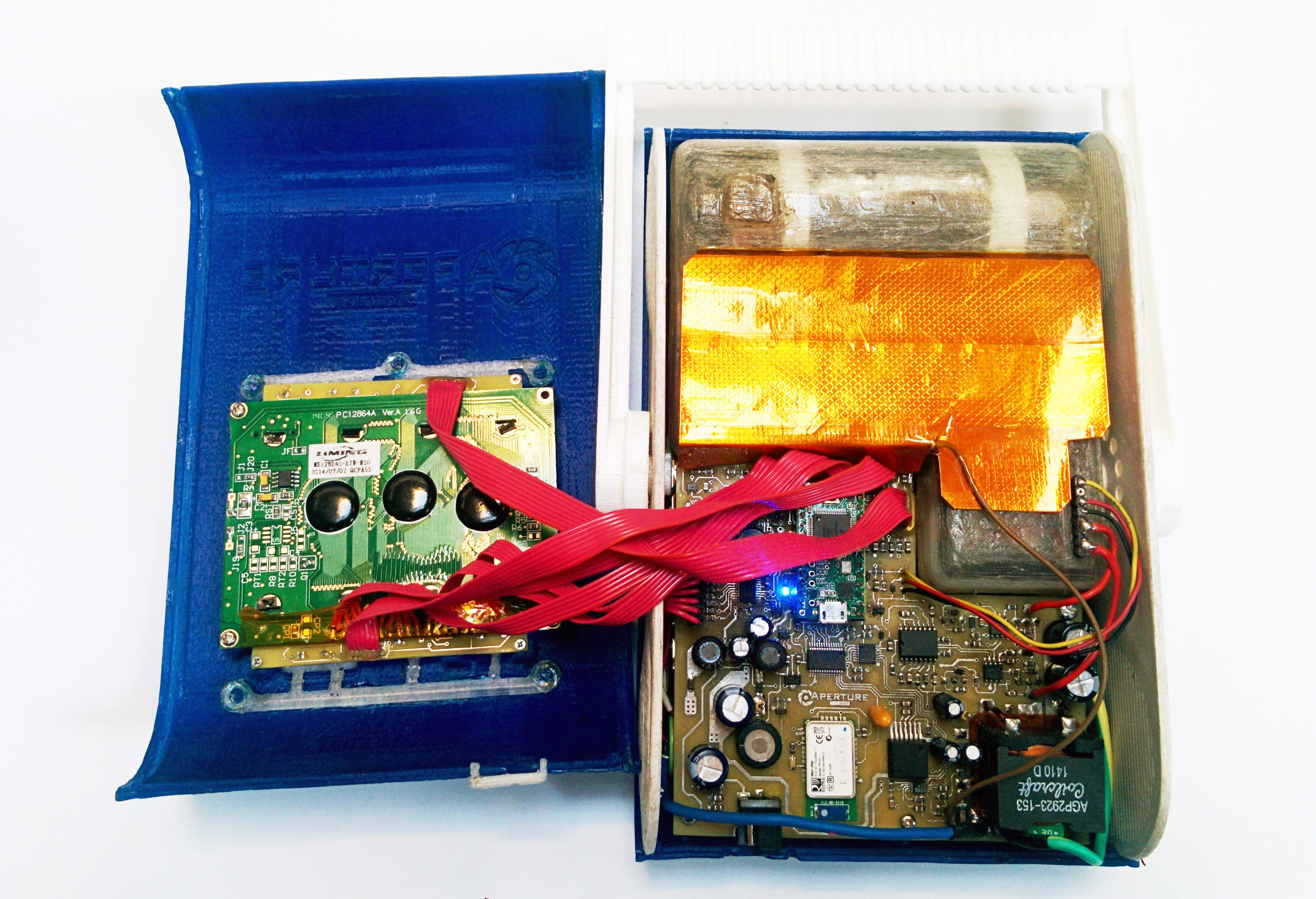

Every so often, I encountered the strangest problem where the machine would simply turn off during an x-ray exposure. This sometimes was preceded by what I can best describe as "static shock sounds". Furthermore, when the x-ray machine's lid was off, it wouldn't have this issue. This puzzled me for a bit, as I had bypass capacitors everywhere, and my oscilloscope didn't suggest there was any noise in the circuit crazy enough to turn it off.

As one would have it, the problem turned out to be

Electro-static noise from the high voltage oil tank, coupling to the LCD panel.

Really. It was the E-Field.

-

-

Copper foil fixed it. Crazy, huh?

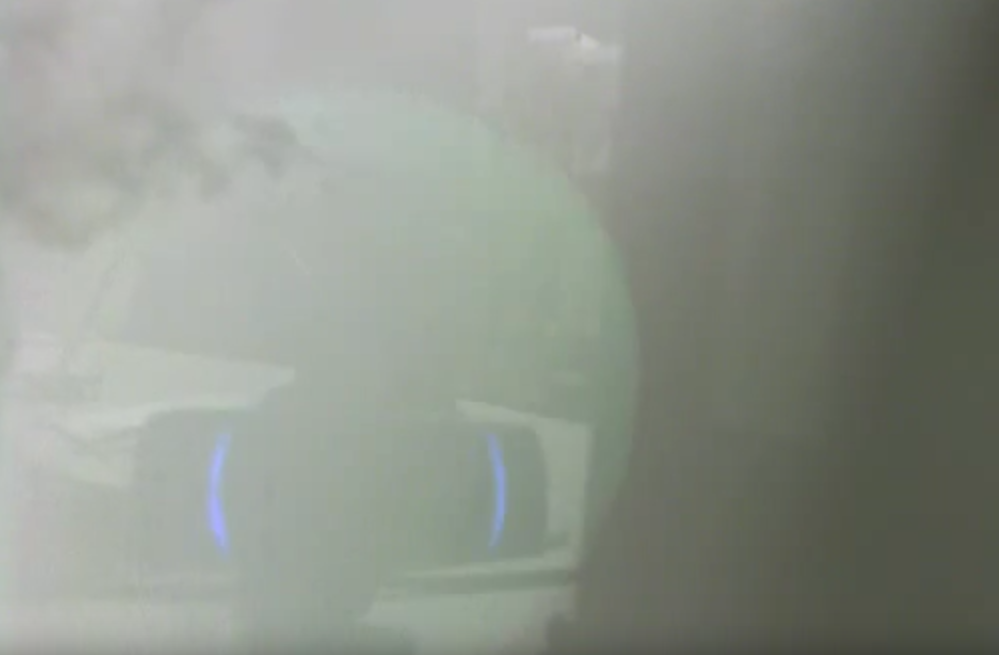

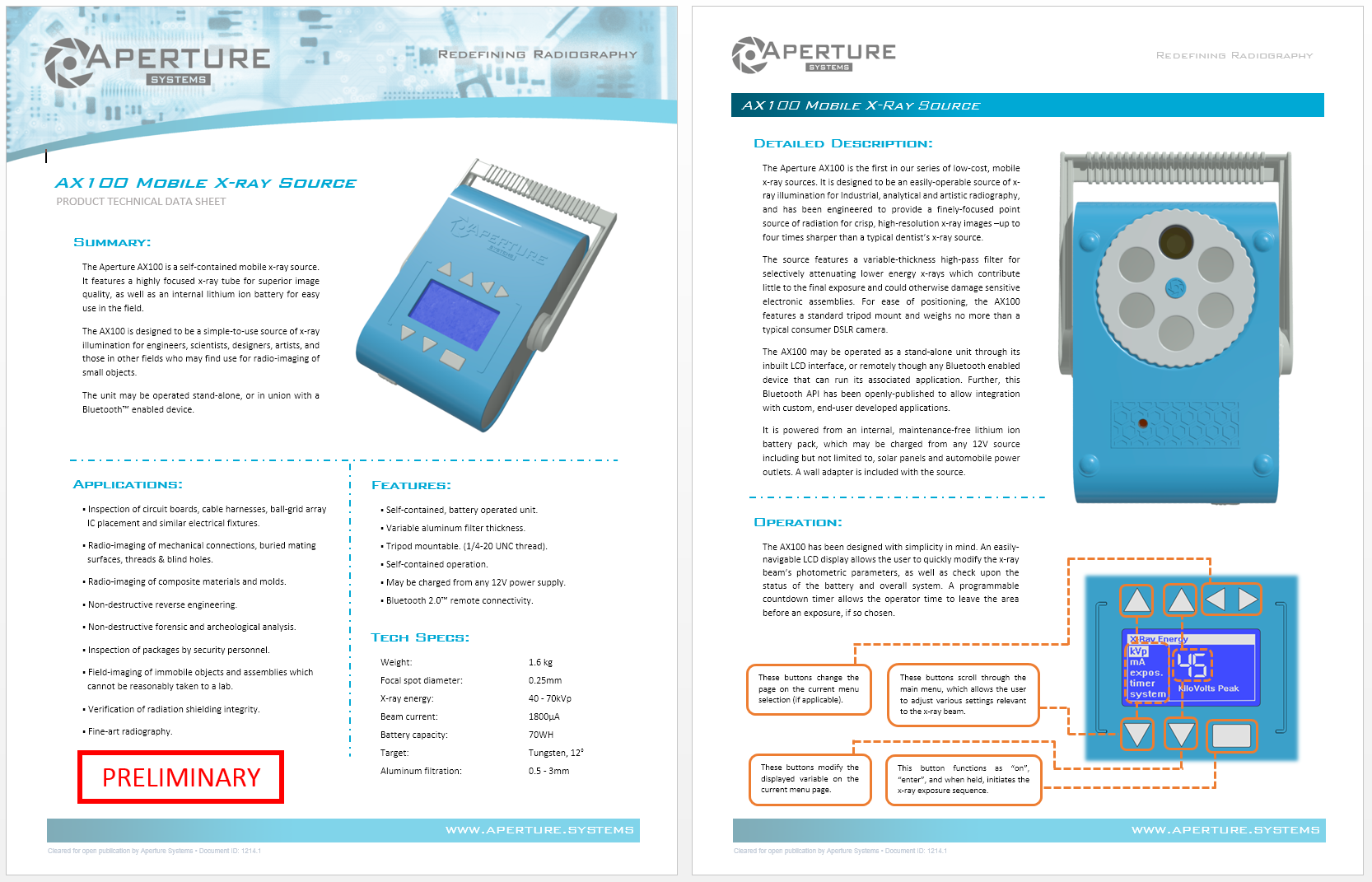

To teach people how to use the x-ray source, and to serve as a short "how to" on radiography, I made a handbook to go along with the machine (which is now lost, for reasons to be described later).

-

-

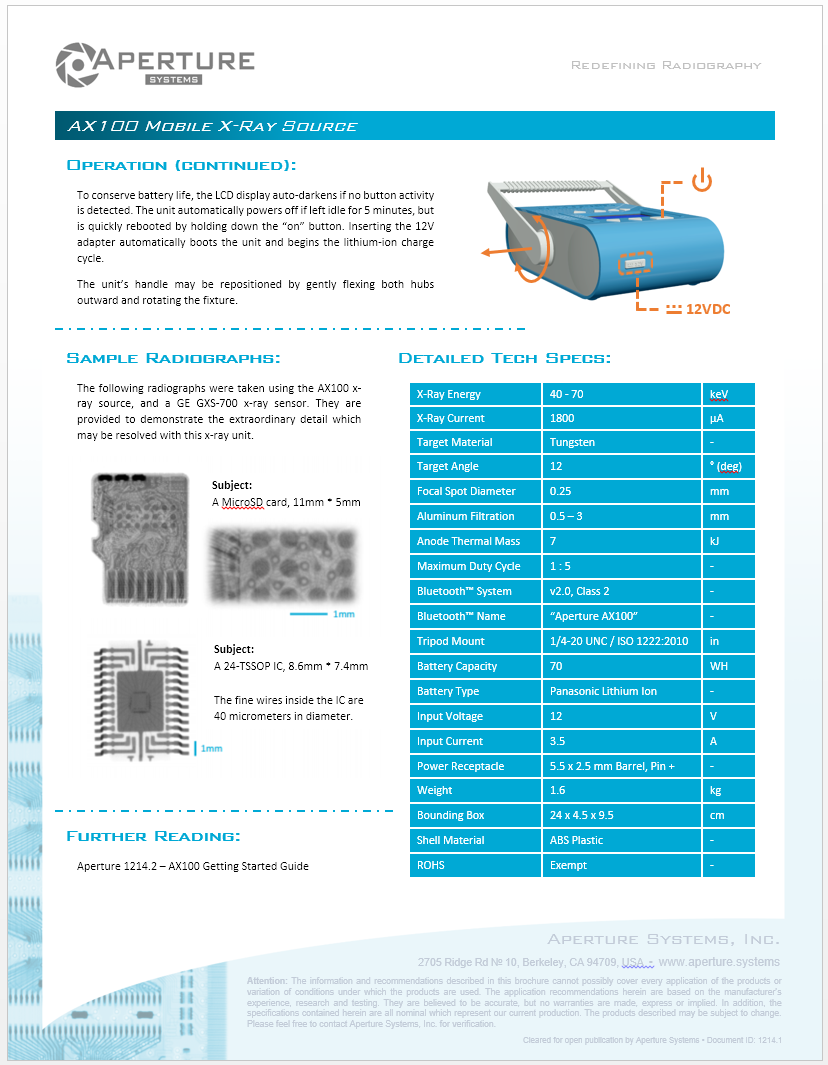

And, a datasheet that describes all of its functions!

-

-

At this point, what I had built was starting to look pretty dang cool!

Adam Munich

Adam Munich

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.