At this point, I had recovered, or rebuilt most of what was lost in February. Feeling (somewhat) better, I set out to design a low cost x-ray sensor to accompany the x-ray source. Film after all, is expensive, messy, and, very logistically troublesome for medical practices in places that have less infrastructure than the USA.

-

-

-

Silicon wafers are expensive, let's use less of them!

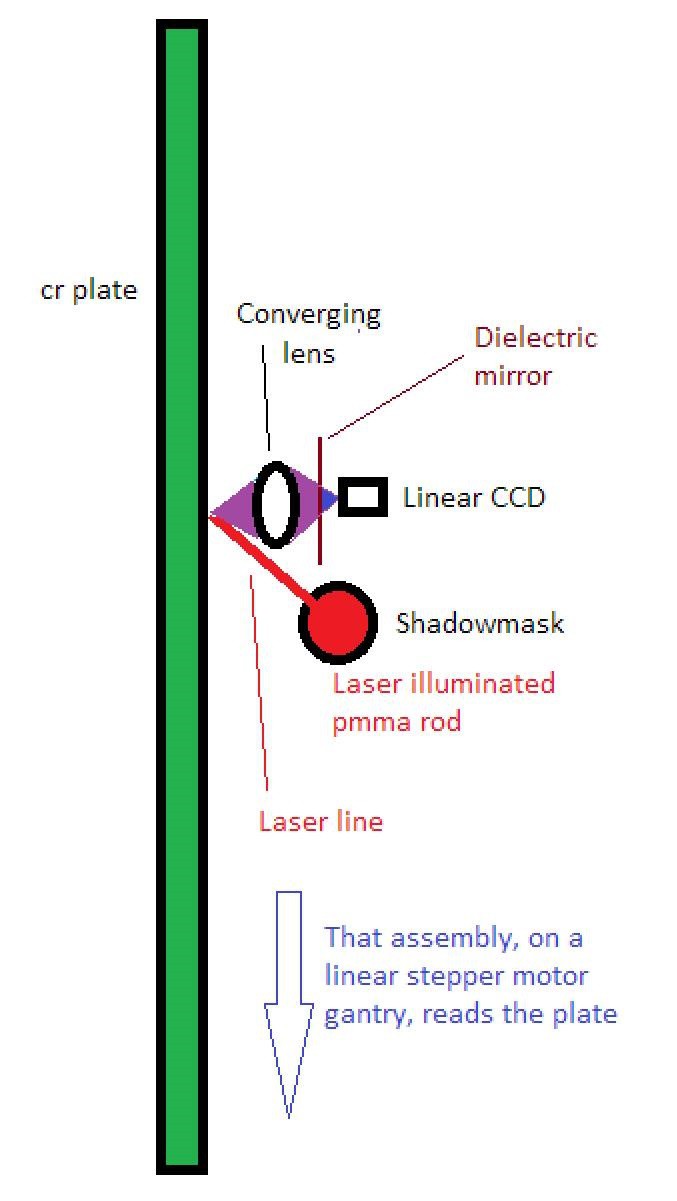

By using a photostimulable phosphor plate, (ie, a phosphor whose previously stored energy may be released by a low-energy photon), we

could in theory, capture a low-dose transmission x-ray, and there-after read it out using an array of 650nm laser diodes linearly focused onto the plate with a cylindrical lens, and a 1D array of CMOS photodiodes which sense the stimulated emission (blue light) via a1D-array of rod lenses and a dielectric, high-pass mirror.

The gantry containing these optics could be placed behind the plate and moved with a stepper motor much like a flatbed scanner, which would allow us to produce self-contained digital x-ray sensors of any size, at a fraction of the cost of using a 2D array of CMOS photodiodes as is done currently.

To build this, I used;

- 10 Laser Diodes

- Europium-doped barium fluorobromide phosphor

- A floppy disk drive

- A logitech webcam

- Plastic rods and optical cement

- An MSP430 and stepper motor drivers

- Dielectric mirrors from a projector

- Solder

- A cardboard box

- An image intensifier (since the webcam is crappy)

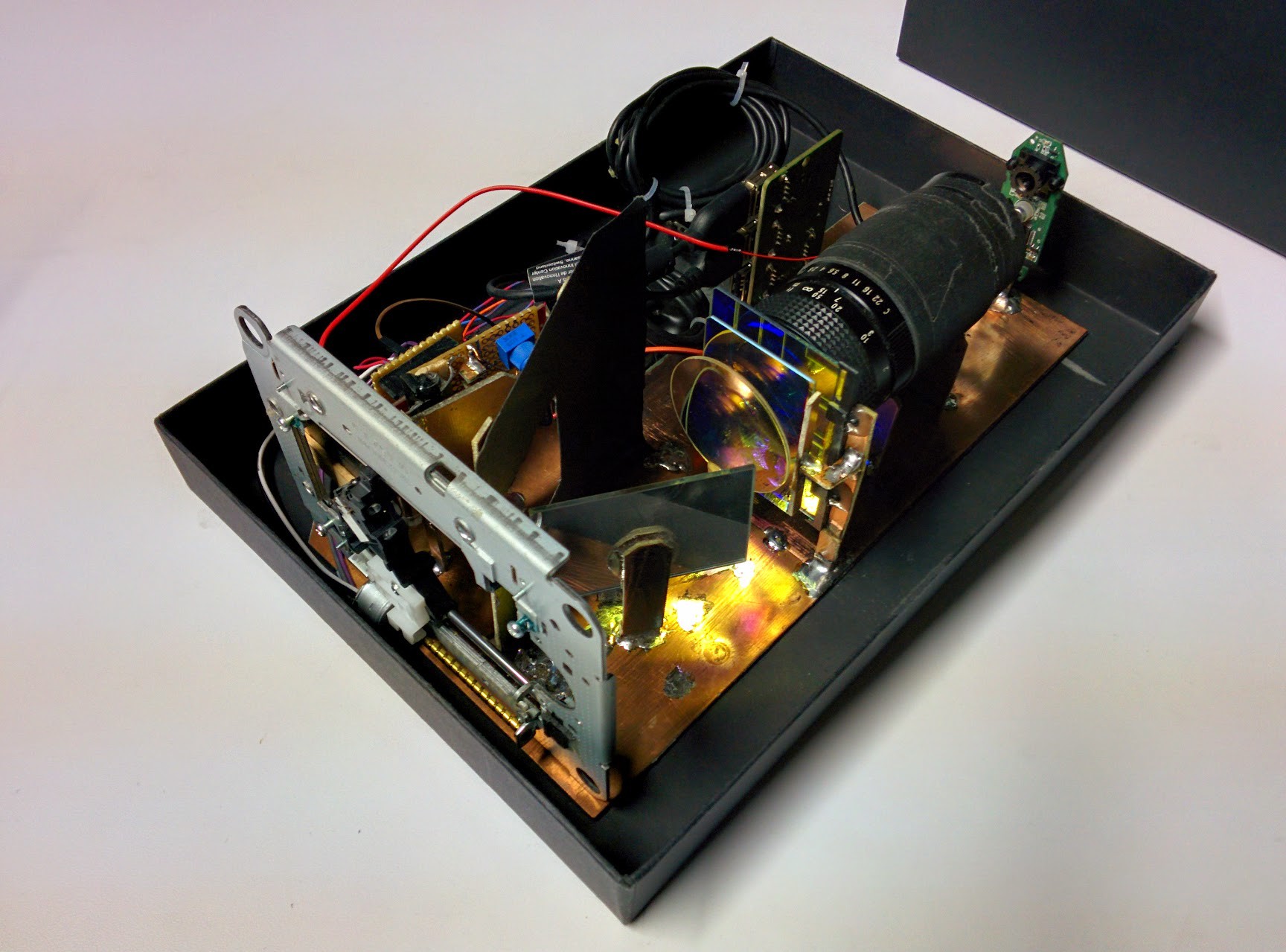

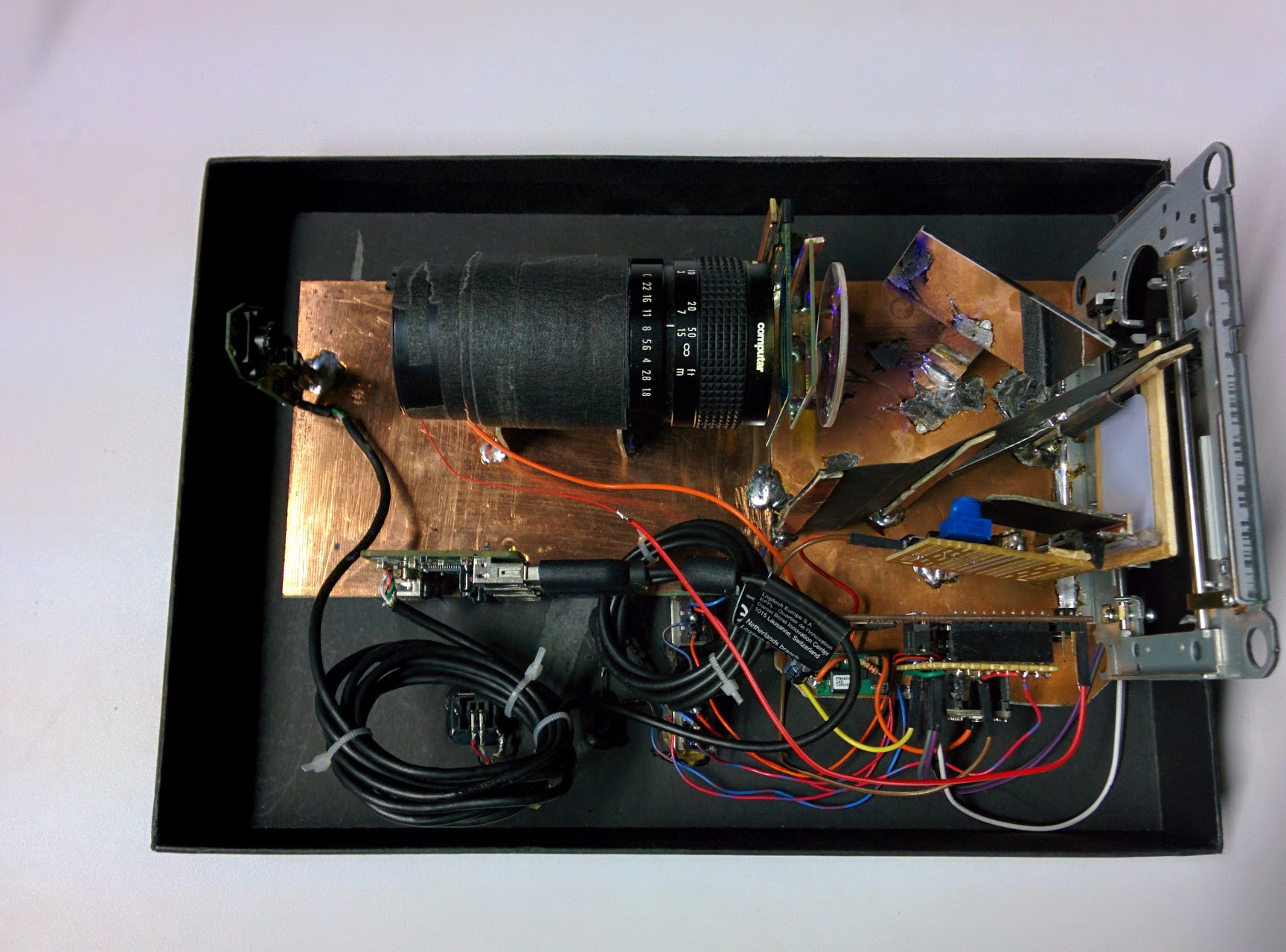

And, built this assembly below:

-

-

Before an x-ray exposure, the laser diodes (on the board with the blue potentiometer) would illuminate and cast a line on the phosphor plate, which scans back and forth a few times to clear any cosmic ray noise that could have been there.

After an x-ray exposure, the laser diodes pulse briefly, and the phosphor emits a blue light that is reflected off a mirror, focused through two dielectric filters onto the image intensifier, and then finally digitized by the camera. This process repeats 130 times, and a collection of 1D images are recorded in a computer by a python script for later stitching.

-

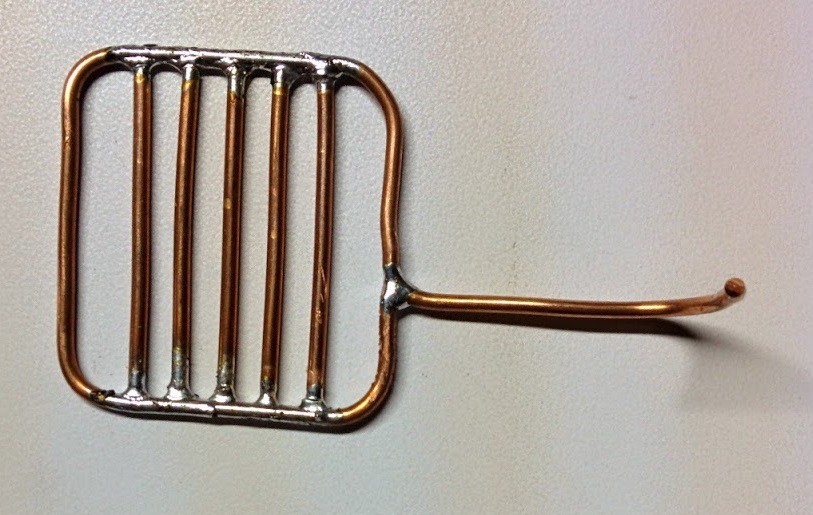

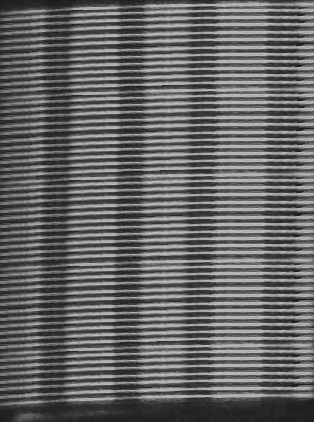

For testing purposes, I built a small copper grille to take an image of.

-

And, this was the result.

-

-

I wasn't too impressed. Never mind the limited lines / mm. That could be fixed.

What was unsettling, was the terrible dynamic range. Despite the two filters, ted light overpowered blue, To fix this, I would need very expensive, tuned laser diodes and a very narrow band filter to record *only* blue light. This would make the cost of a real sensor prohibitively high.

Adam Munich

Adam Munich

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.