In July 2013, I started prototyping my initial idea to use a wet scrubber as a counter-top kitchen recirculation hood. The design combines a Venturi scrubber and a sieve plate wet scrubber, and the airflow is provided by a small vacuum motor.

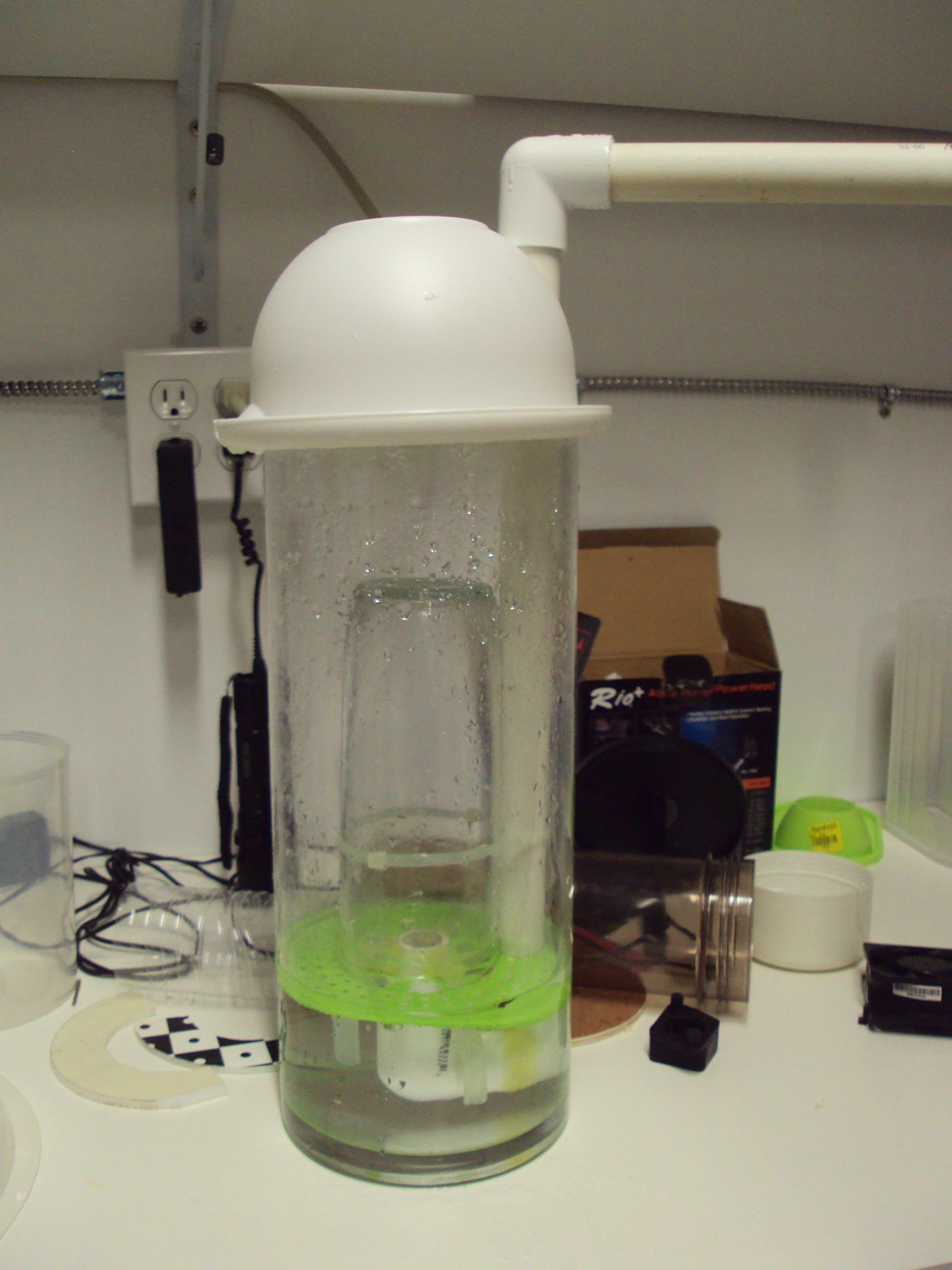

The entire unit is comprised of a vent hood on a boom and a tall cylinder containing the wet scrubber unit. The vent hood is mounted on a retractable boom and can be swung over a kitchen range to suck in dirty air. The wet scrubber unit consists of a Venturi nozzle set in a sieve plate submerged in water. The dirty air enters through a pipe opening in the hood and is routed to the bottom of the wet scrubber unit. The air then passes upwards through a Venturi nozzle, creating mist. The misty air impacts a cup, reverses direction and bubbles through a sieve plate. The mist is then separated from the air as it hits mist eliminator plates. The now clean air exits through the top of the wet scrubber unit. The components of this assembly is described in detail below.

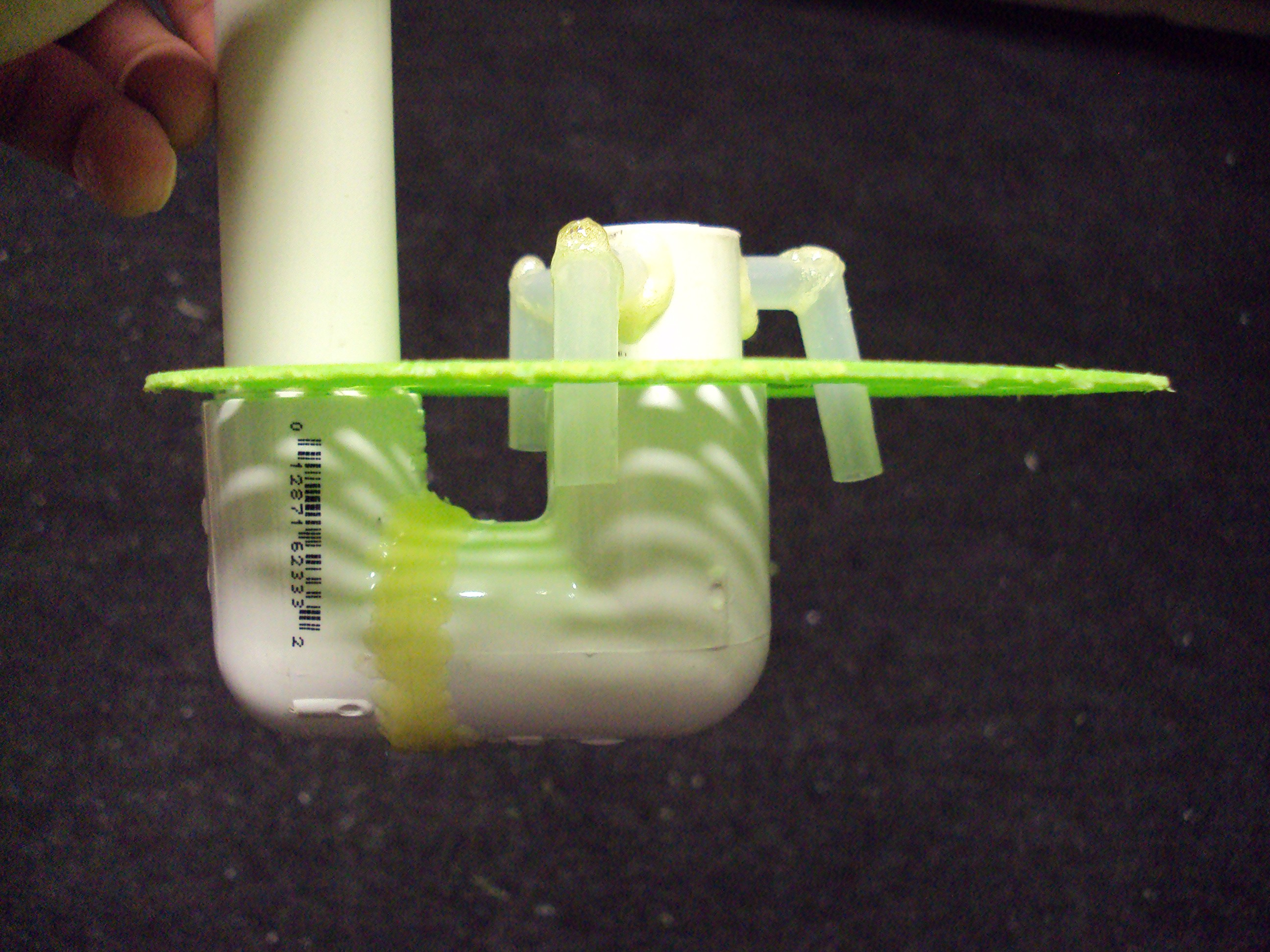

The Venturi nozzle is created by inserting 3 plastic tubes perpendicularly into a PVC pipe and cutting the pipe at an angle. The entire nozzle is fitted inside a sieve plate.

This nozzle assembly is submerged in water with the water level above the sieve plate. As dirty air passes through the nozzle, the Venturi sucks water upwards and induces a spray of mist that impacts the dirty air. The impaction between particulates in the air and the water droplets in the mist encourages the particulates to separate from the air and cling onto the water.

On top of the Venturi nozzle, a glass cup forces the misty air to reverse direction. As the air impacts the wet surface of the cup and changes direction, more particles in the air are forced into the water droplets. The cleaner air then enters the water a second time, this time bubbling up through the sieve plate. This bubbling action allows more particulates to be picked up by the water through diffusion.

From there the misty air is passed through a mist eliminator, which separates the particulate burdened water droplets from the clean air. The clean air is then allowed to exit the scrubber unit.

My first prototype was made from a large glass vase, PVC pipe, Tupper ware, a glass cup, a cake container, and a small vacuum motor. Here is a video of its operation (Warning: it is rather loud!):

What I learned from this first prototype is that the vacuum motor is hella loud. The piping is way too small and does not allow adequate air flow and suction from the hood. Also in this prototype, the VOC's are not adequately scrubbed when I tested on fumes from burning butter, which means that an adsorbent bed may need to be added.

This led me to my current design, which is to use a high voltage booster stage and a cyclonic self induced spray (orifice) scrubber. This will allow for more contact time between particulates and the scrubbing liquid, along with greater air flow.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.