In 2014 up till today I have been reading and researching best practices in wet scrubber design. In my next iteration I want my design to have greater air flow without compromising performance. For my wet scrubber to be effective in removing odor, VOCs (volatile organic compounds), and smoke particles as I have intended, IT NEEDS TO BE ABLE TO REMOVE PARTICULATES THAT ARE LESS THAN 1 MICRON (UM) IN SIZE. Conventional wet scrubbers have a practical limit to the size of particles it can scrub from the air. The best wet scrubbers can scrub 99% of particles above 1um. For sub micron particles, another technique is typically used. ESP's (Electro Static Precipitators) have excellent performance for sub micron particles, matching that of HEPA. Wet scrubbers can have also have electrostatic augmentation, which is done by electrifying the dirty air before piping it through wet scrubbers and/or by oppositely charging the scrubbing liquid in the wet scrubber. I plan to use this technique of electrical augmentation for my enhanced wet scrubber invention.

To provide greater air flow without performance loss in my new wet scrubber design I knew I needed the following:

- larger piping

- higher turbulence between the air and scrubbing liquid

- longer contact time

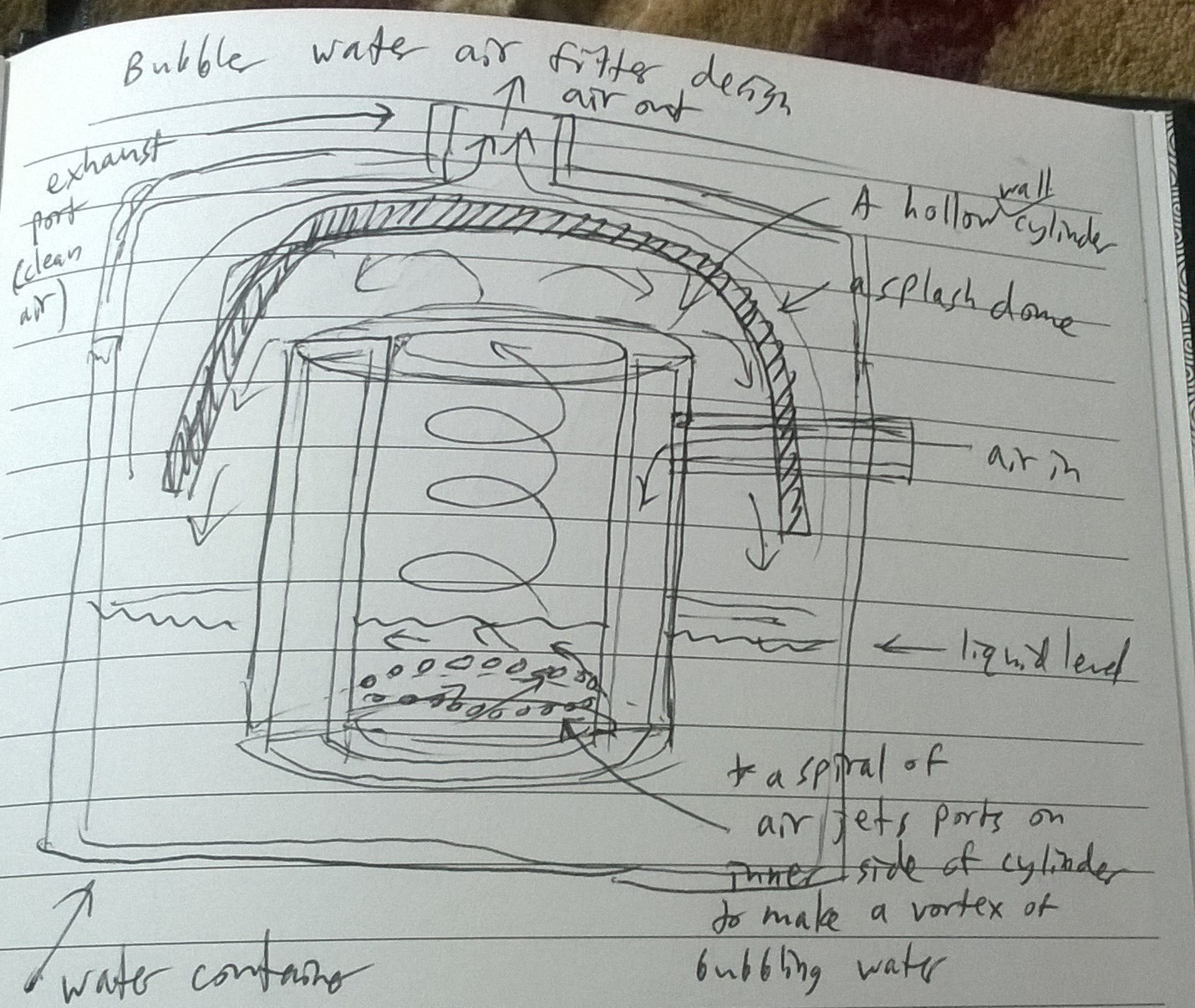

On August 14th 2014, a design dawned on me how to do just that. The wet scrubber would be a large hollow walled tube that has an inward spiraling "sieve plate" which is comprised of many nozzles directed at an angle to the tube surface, forming an inward spiral towards the center of the tube. This tube is submerged in a tank of water (scrubbing liquid) with the water level above the nozzles. The dirty air would be piped into the hollow tube wall and directed through the nozzles into the scrubbing liquid at an angle. The impact of the air hitting the scrubbing liquid separates particles from the air. As air travels through the nozzles and into the liquid, it will accelerate the scrubbing liquid into a vortex. As the vortex of liquid accelerates past the nozzles at an ever increasing speed, it will increase the impaction force between the air and scrubbing liquid, thereby increasing the scrubbing effect. The mist will then spiral upwards and exit the top of the tube. The cyclonic action caused by the spiraled nozzles allow longer contact time between the scrubbing liquid and the particulate laden air, as the misty air would travel in a longer spiraling path. The air flow would be limited only by the number of nozzles and tube diameter. At the top of the tube would be a large dome to act as a mist eliminator. The particulate laden water would spiral and impact the dome. The droplets, along with the trapped particulates, would fall back into the pool of scrubbing liquid and the clean air would exit upwards from the tank. I don't think this specific design has ever been done before so I may end up writing a patent application.

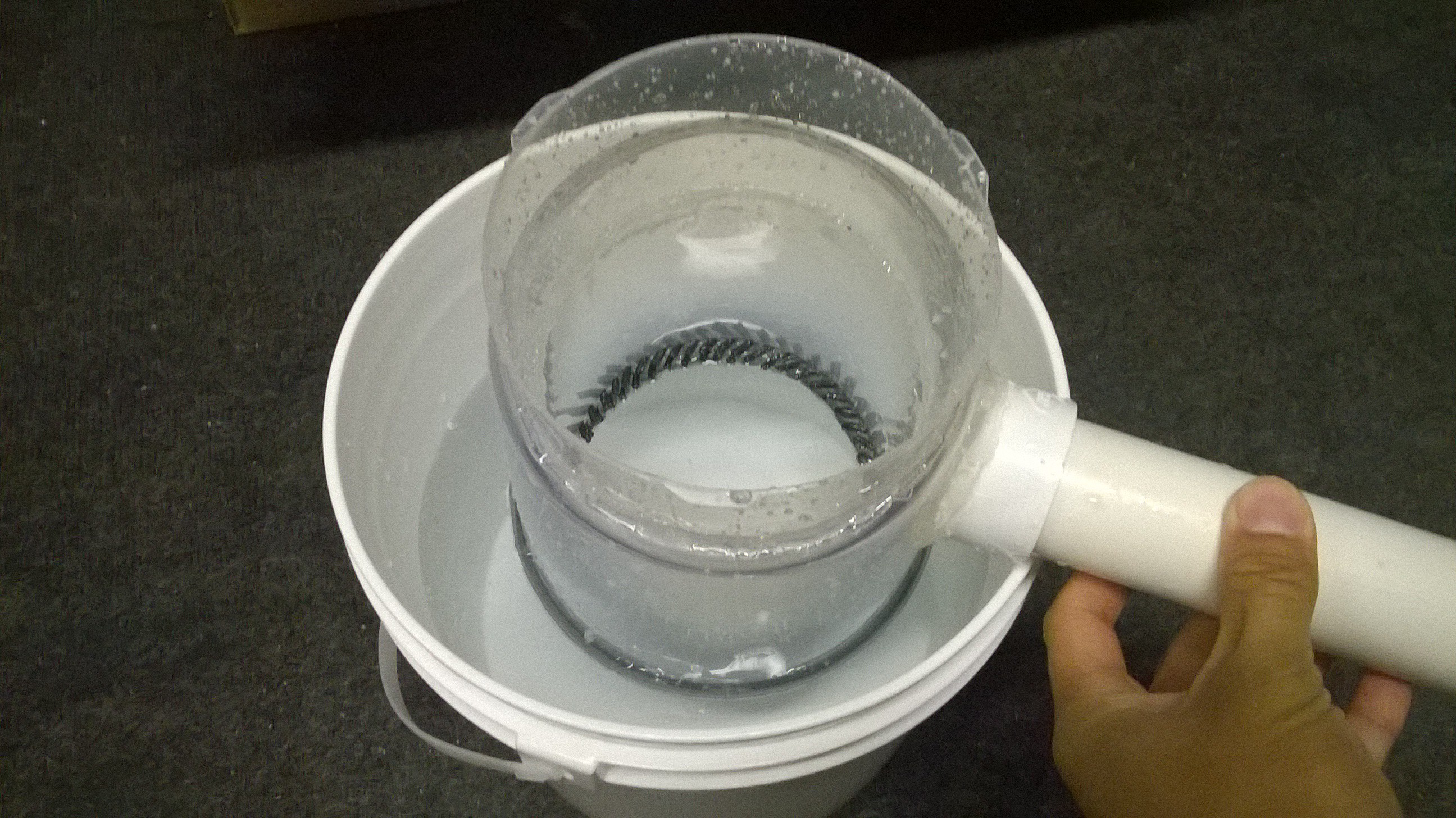

I quickly began to prototype this new idea using CD spindle cases and coffee stirrers

My initial setup made a huge mess as I did not have a splash dome on top of the tube. This design however worked wonderfully.

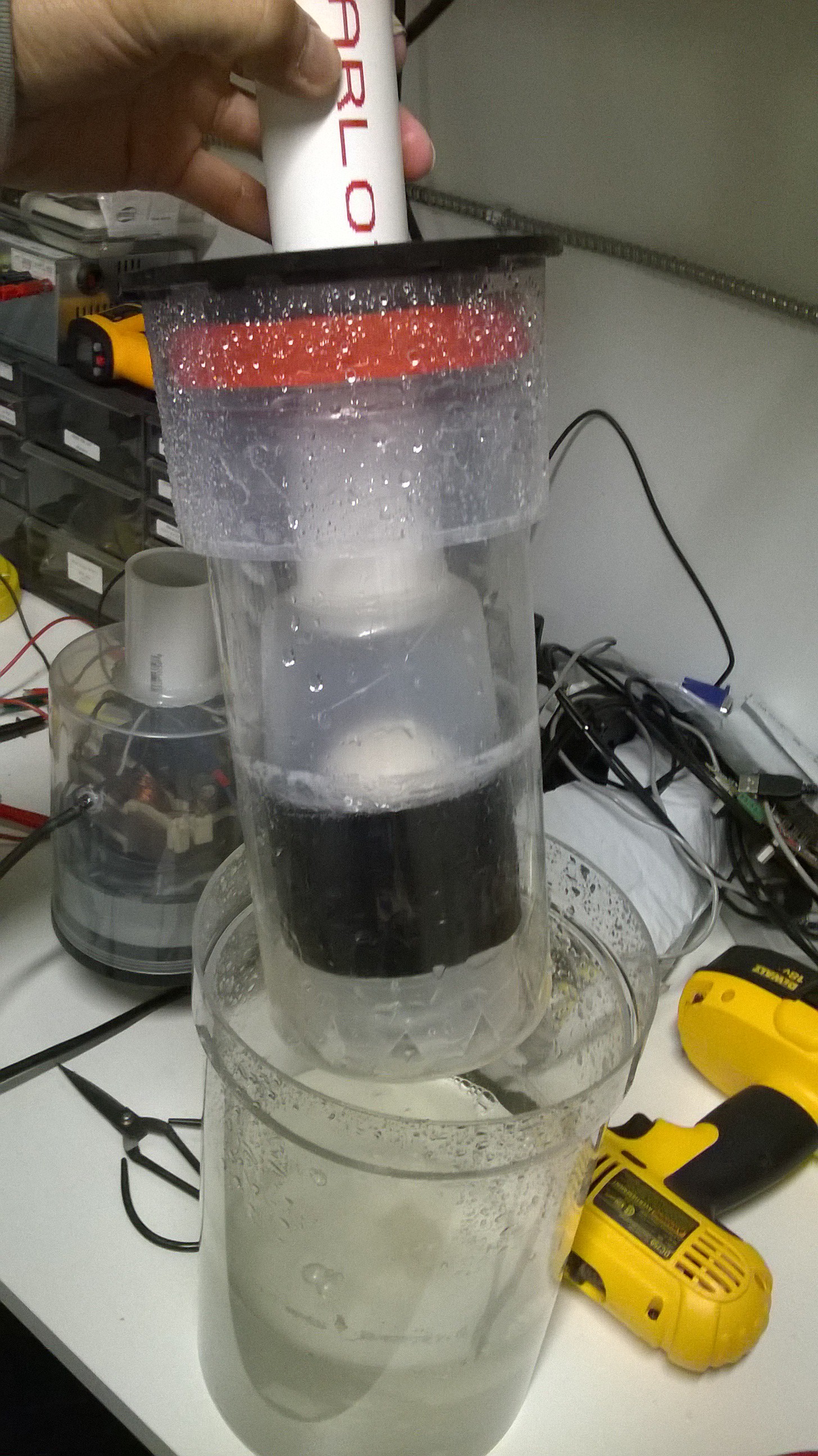

I wanted to see if I could make the design smaller so I experimented with a couple other prototypes of different shapes and sizes.

I strived to get the device even smaller to maintain a small counter top form factor.

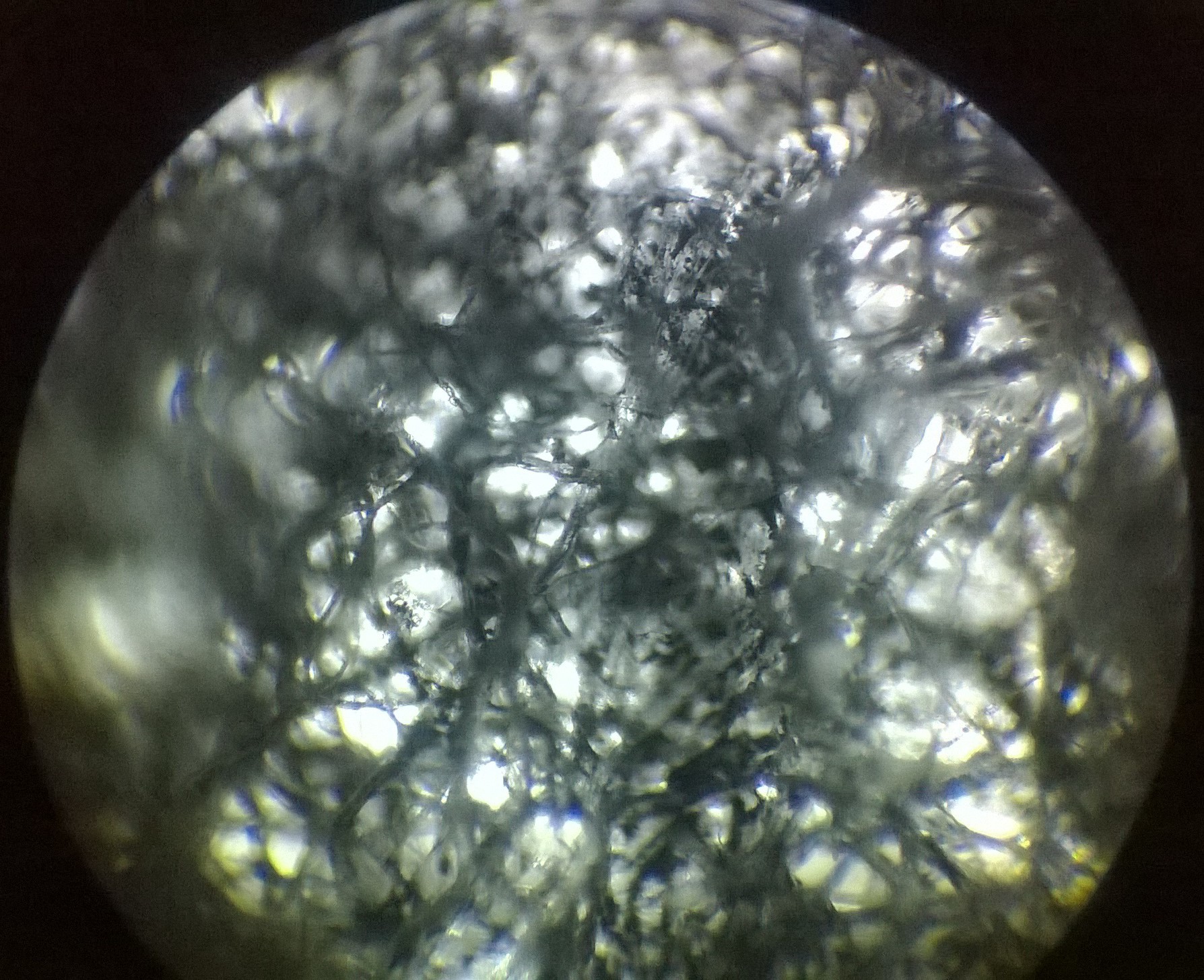

To test the scrubber's effectiveness, I had it suck up activated carbon dust, and placed a paper towel at the exit port to see what got through.

I bought a compound microscope to see the results. What I found was astonishing.

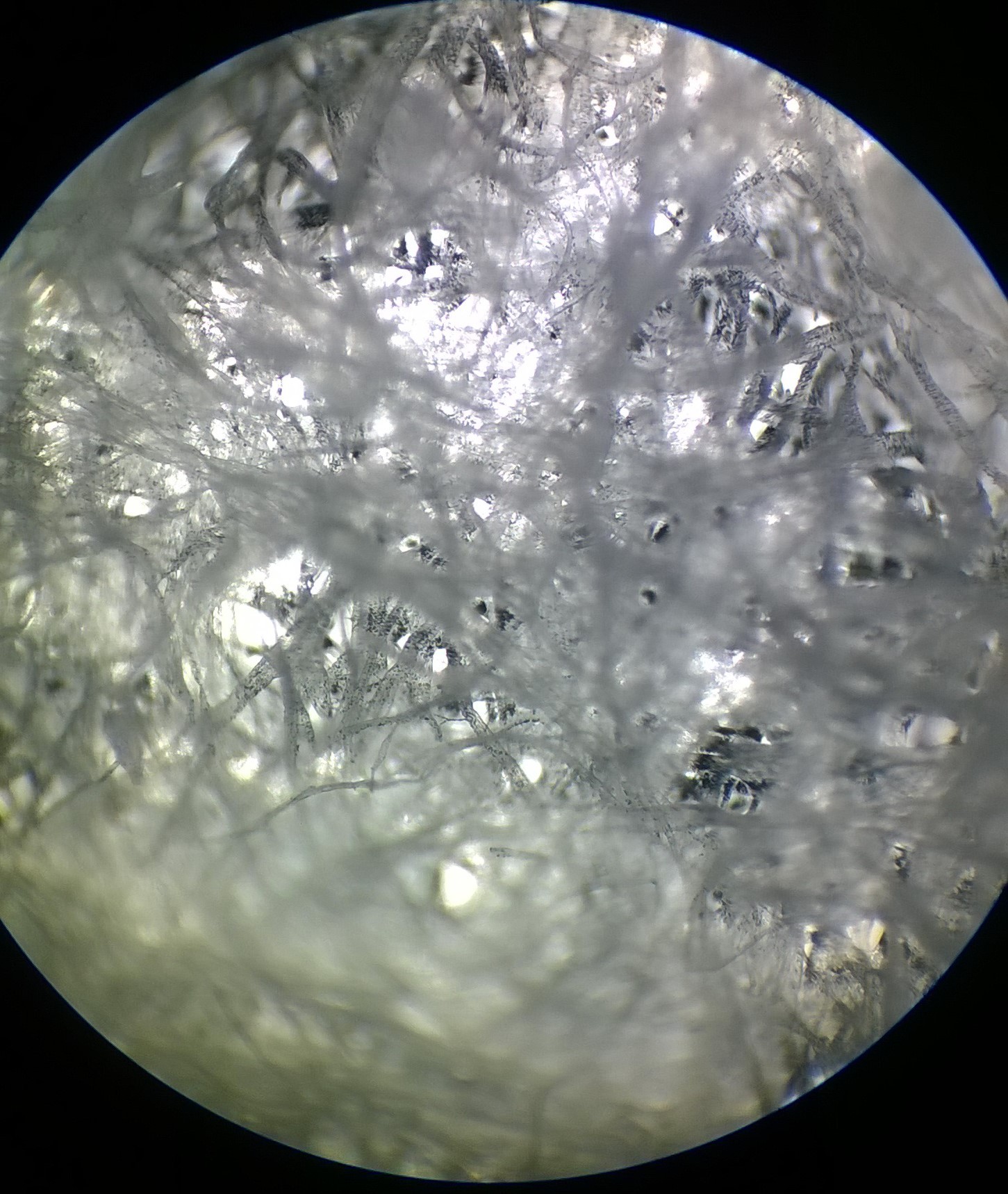

This image below is the control, piping activated carbon dust unfiltered directly into a paper towel.

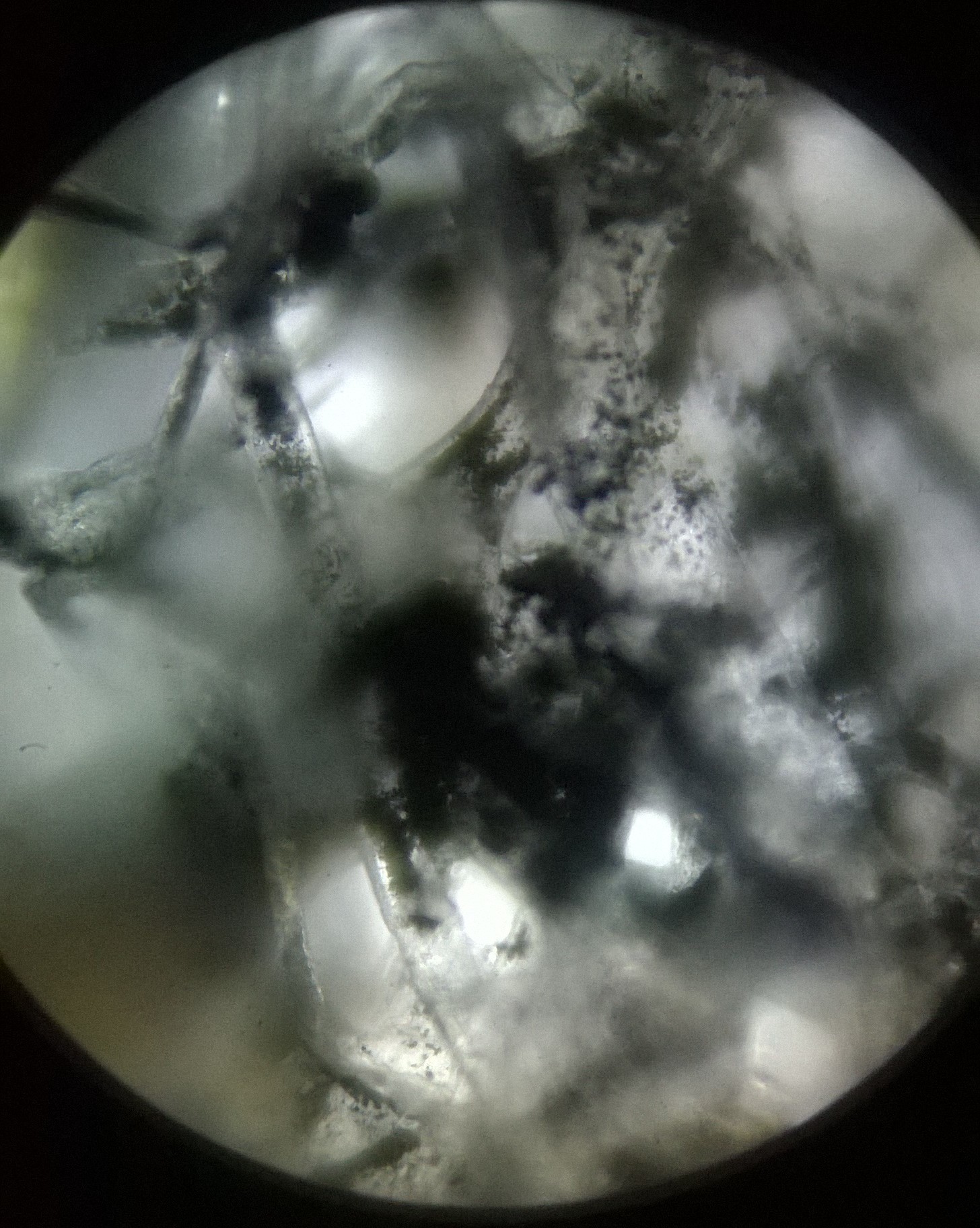

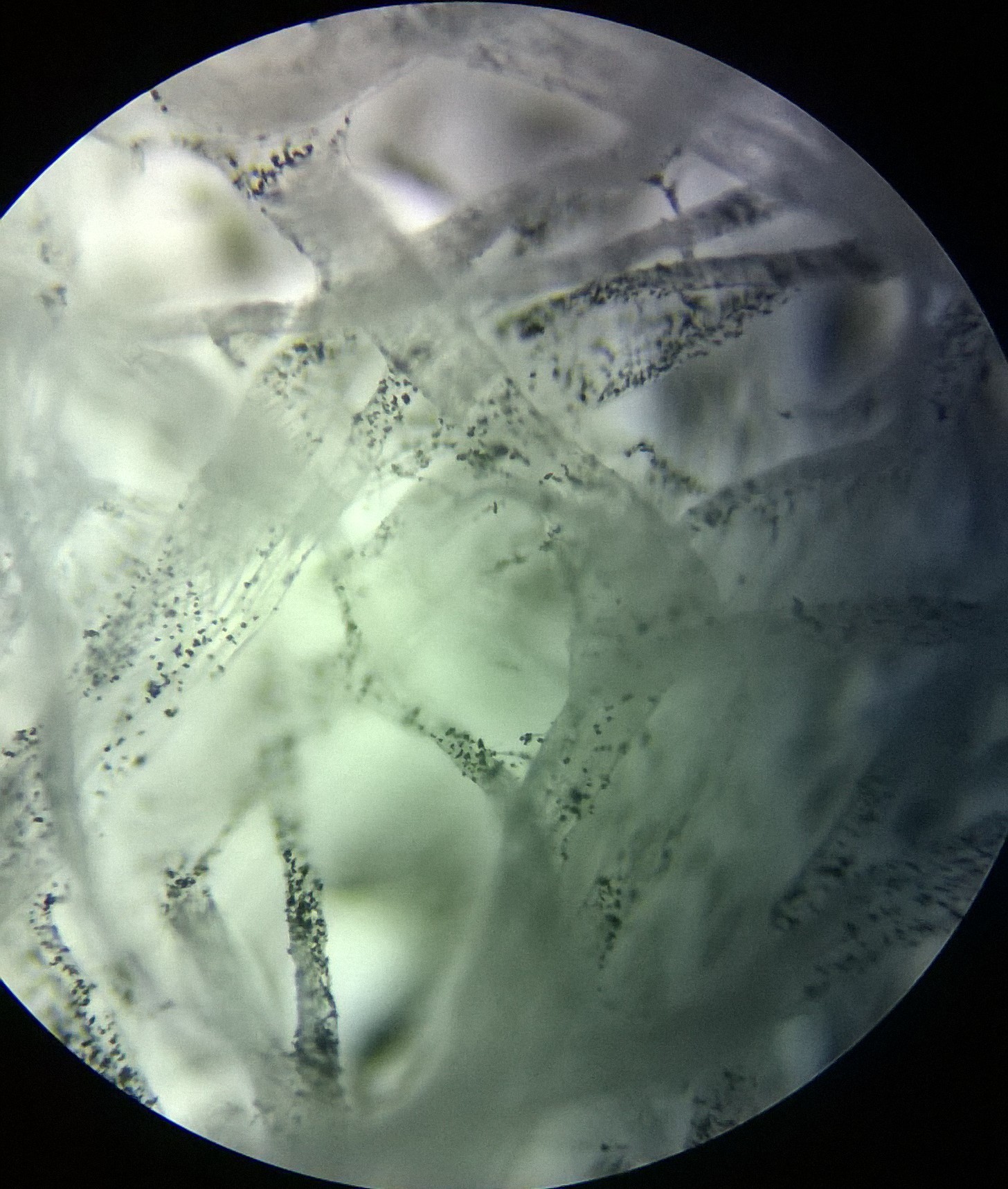

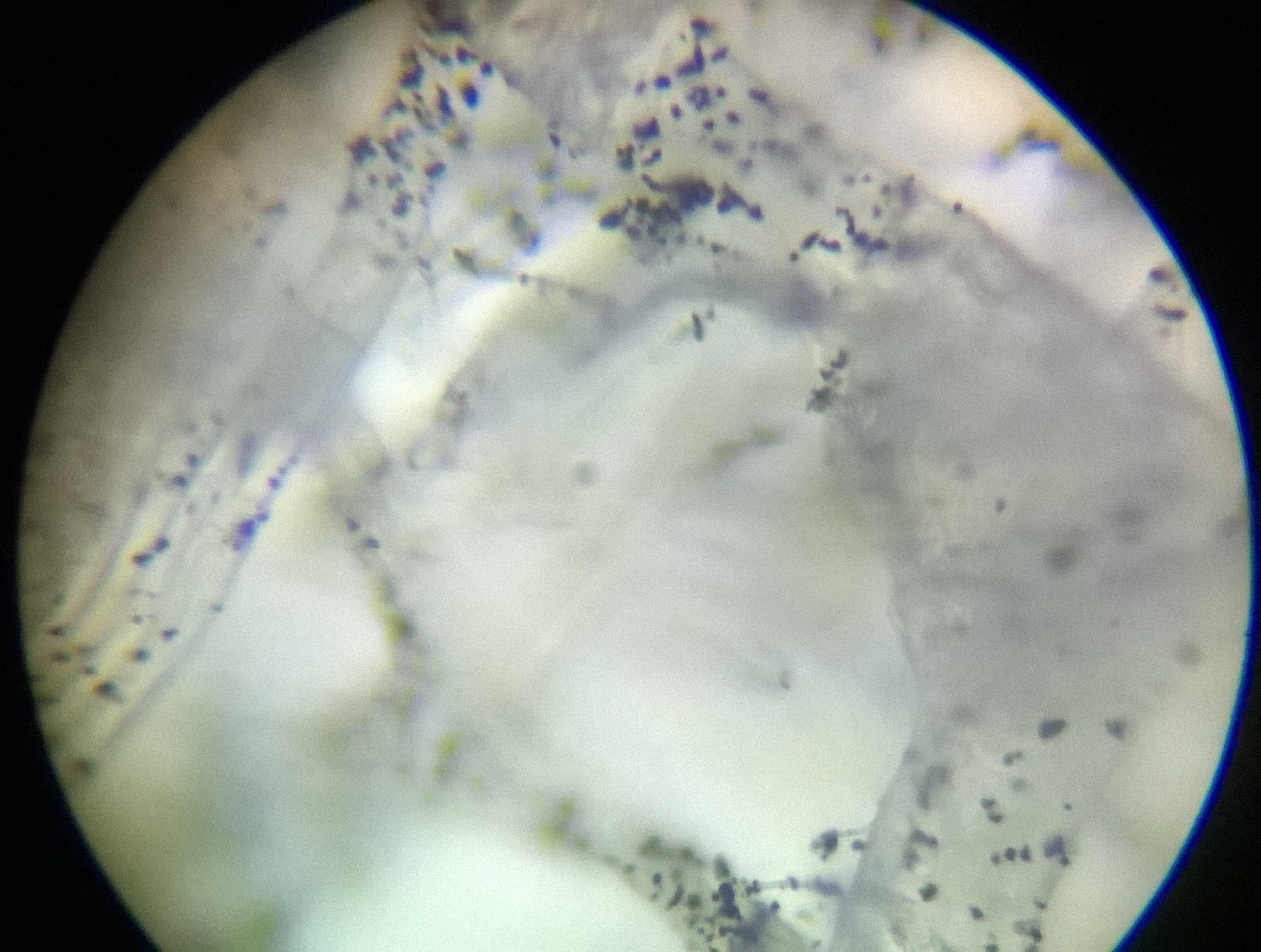

This is an even more zoomed in view of the sample taken with the wet scrubber.

This is an even more zoomed in view of the sample taken with the wet scrubber.

The particles that penetrated the scrubber were about 2-5um in diameter, approaching the limits of that of an orifice scrubber! Not bad for a counter top device. This is still not great however and definitely not up to par for my end design.

It was time to implement the electrostatic enhancement stage.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.