Above is my submission video...

First Tests of My Latest Prototype

I tested my latest prototype first by filling it with water and turning on the electricity and the vacuum motor. ZAAAP!! the high voltage electricity applied to the cylindrical charging grids kept shorting out to the water that the wet scrubber was submerged in and the lights kept flickering in my lab. This did not bode well.... I had to go plan B and add a wired brush inside the inlet pipe to perform the charging and disconnect the cylindrical charge grids that were inside the hollow walled tube of the wet scrubber. I was a little sad as plan B does not allow the incoming air much time to be ionized before reaching the wet scrubber nozzles.

Moving onwards I turned on the electricity with plan B using the inlet pipe charging brush. It made a nice satisfying HISS! and I could hear the air being ionized with an electric wind. At least plan B works, even if it is only a tiny bit.

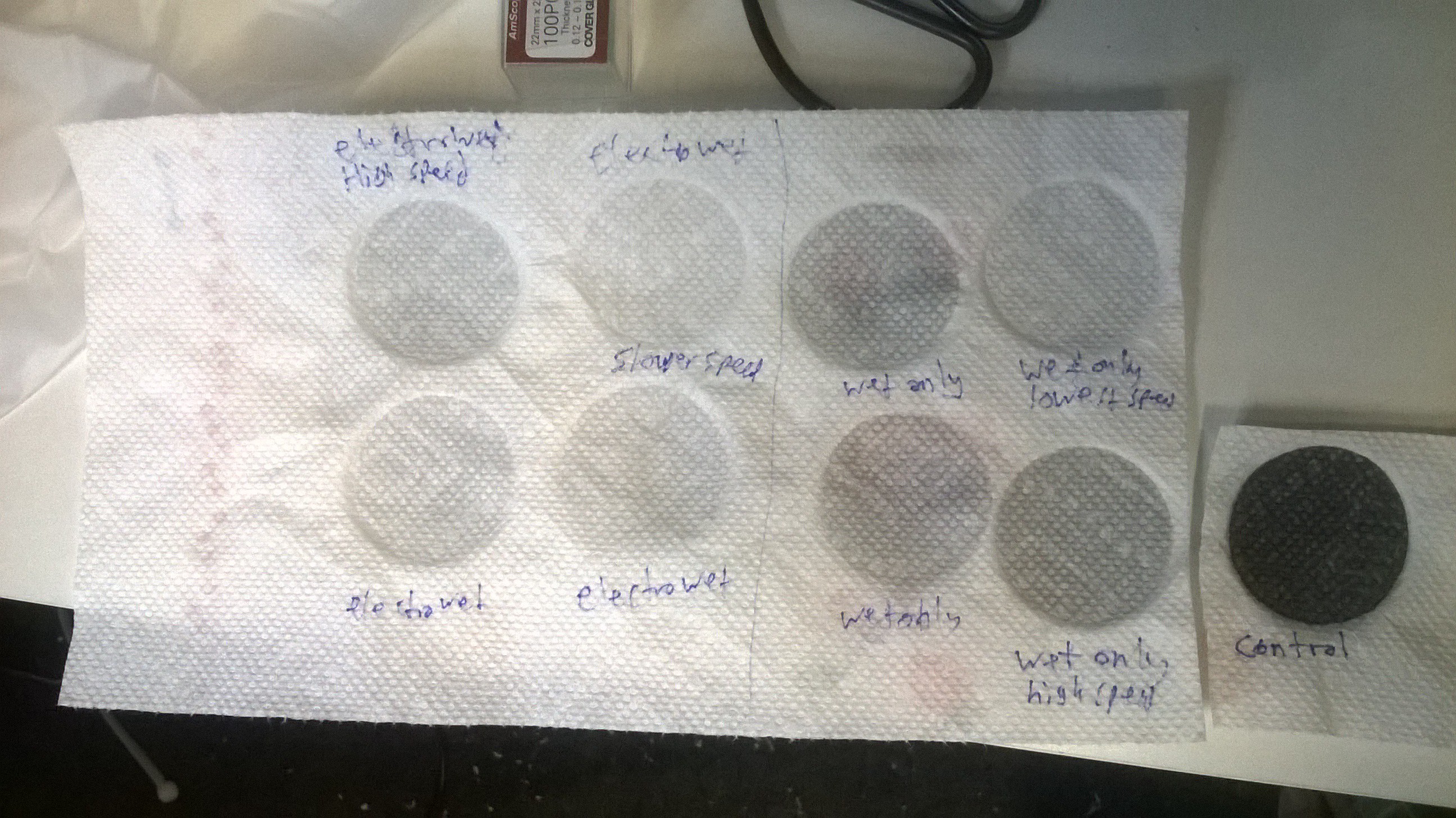

I went on to test my prototype by piping in activated carbon dust into the inlet and placing a paper towel at the exit port to see what got through. I first created a control sample by bypassing my entire wet scrubber filtration and sucking the carbon dust directly into a paper towel. This made a very black sample.

I then went ahead and tested the wet scrubber without electrical augmentation using the carbon dust and paper towel to sample. For the final test, I turned on both electrical augmentation and wet scrubber.

The data showed that the wet scrubber filtered most of the large particulates, and the electrical augmentation had only a slight effect in capturing more particulates. The samples were not pure white however which was disappointing. The negligible performance of the electrical augmentation was expected to some degree as there was barely any time for the incoming air to ionize traveling at high velocities. Had the original design not shorted perhaps, the cyclonic spiral motion would give a longer path and more time for the air to properly charge. Furthermore, part of the disappointing performance may have resulted from the fact that putting a paper towel at the exit port places a huge air resistance to the system causing the wet scrubber to not work as efficiently so I may have botched my results by reducing the air flow.

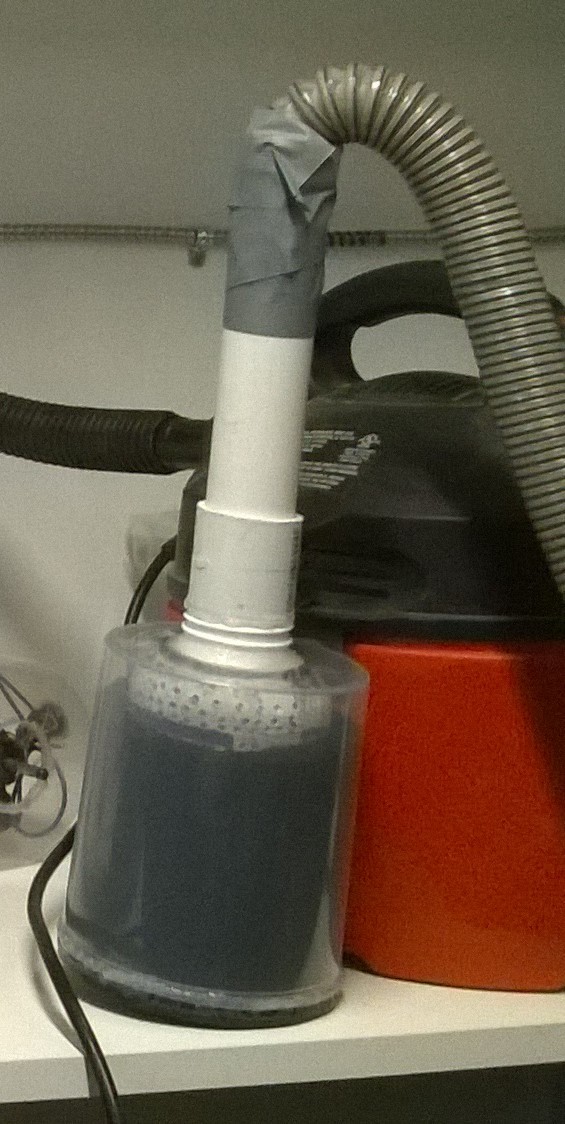

I performed multiple tests at different speeds. Strangely however, the system seemed to favor lower speeds as the samples for lower speeds seem whiter. That is counter intuitive as higher wet scrubber velocities tend to mean better performance. This may mean that the method of how I was piping in the carbon dust into the inlet port was flawed. I simply stuck a pipe into a container containing loose carbon pellets with cloth barrier preventing the large pellets getting sucked in so only the carbon powder would get through. This probably caused greater air resistance than the paper towel and therefore slower speeds simply sucked in less carbon dust than higher speeds. A picture of the jury rigged canister of loose carbon is shown here below.

I now know where to focus my efforts next time and that is to get the electrostatic booster stage working properly without plan B. There does exist a trade off condition that higher air flow improves the wet scrubber performance due to higher impaction velocities but lower air flow improves the electrostatic charging as it gives more time to ionize particles. It will be quite a challenge to balance these two factors in my next design. I also must improve upon how I am testing the system so my data is not as confusing and counter intuitive.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.