Tube ESP

As I yet again went back to the drawing board, I decided I would pursue a tried and true method in designing an electrostatic precipitator to deal with the sub micron particles along with any new design I'd come up with just in case the new idea didn't work as planned.

For my ionizing circuit, I was going to build a tube electrostatic precipitator that would either go before or after the wet scrubber as a separate stage. A tube electrostatic precipitator has a thin wire going axially through the center of a tube that is held at high voltage to produce corona that ionizes the air. Particulate laden air is passed through the tube and ionizes the particles such that it sticks to the walls of the tube.

Although I intended to do this originally but was stopped by the fact that these devices produce Ozone, I would make the design such that it would minimize Ozone production by using positive corona and then absorb any produced Ozone into the scrubbing liquid as well as the activated carbon stage at the end. The Ozone absorbed into the scrubbing liquid will help sterilize it and help oxidize any VOC's that enter it, the remainder of the Ozone should be absorbed by the activated carbon stage.

I purchased several round galvanized gutter downspout pipes from the hardware store and some steel wire. I rigged one of the pipes to run a single steel wire along the center of it and connected it to my high voltage circuit. As the pipe was energized, I shot the fog machine into one end. NO SMOKE CAME OUT THE OTHER END! As I turned the high voltage electricity off, the smoke started to pass through pipe. It was like magic! At last, I had a device that worked for sub micron particles!

Now it was time to cut up the pipe into sections so I can fit it into a housing. I used a general guideline that there needed to be 200-800 ft^2 of collection surface per 1000acfm. I approximated that my vacuum motor is providing roughly 100cfm. If I cut the 2inch diameter 10ft length pipes into five 2ft lengths, I could use five pipes go give me 25 pipes total with one pipe section giving me a little over 1 sq ft each. The total square footage of the collection surface being about 25ft^2 for 25 pipes. Electrostatic precipitators are quite bulky!

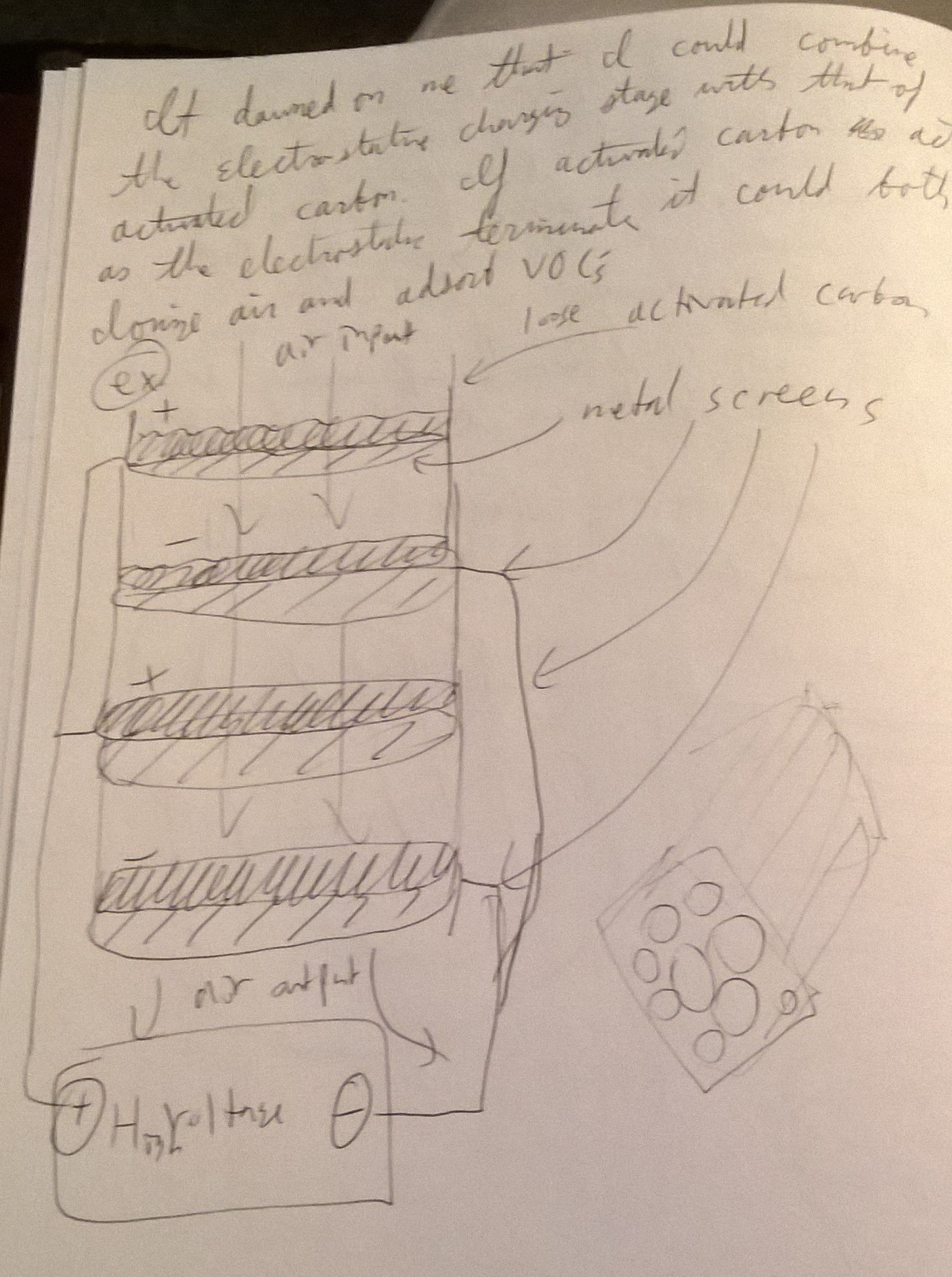

Electrified Activated Carbon ESP

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

this is so awesome!

Are you sure? yes | no