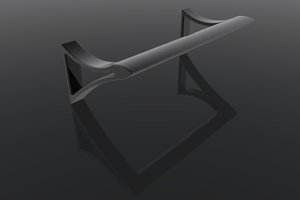

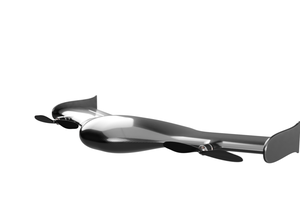

Most of the components have been CNC-milled out of aluminium (in case of the table top), solid stainless steel (legs, playing pucks and hexagonal corner ornaments) and a special composite which has been given a coating of automotive-grade black paint (for the frame). The total design and production time for the final prototype was just over eight months and we have gone through many intermediary stages, tried out numerous production techniques and various materials before settling on the current configuration (it's a shame we have found hackaday.io so late, otherwise we could have kept a log here!). Producing it as a one-off has proven to be quite a challenge, however, in the end we are happy with the way it's turned out and, should the market give us the OK, we are ready to take on the next challenge: mass production (whilst maintaining the same level of quality, of course).

0%

0%

The Scientifical Hamster Table

A unique, top quality multifunctional table with a stylish and innovative design, which easily converts into the best game table ever.

Scientifical Hamster

Scientifical Hamster

TAIBHSE DESIGNS

TAIBHSE DESIGNS

Joseph Prosnitz

Joseph Prosnitz

Naman Pushp

Naman Pushp