I ran two tests today:

- does the overtemperature detection for the heaters work?

- how does the system act with galden inside?

Overtemperature Detection

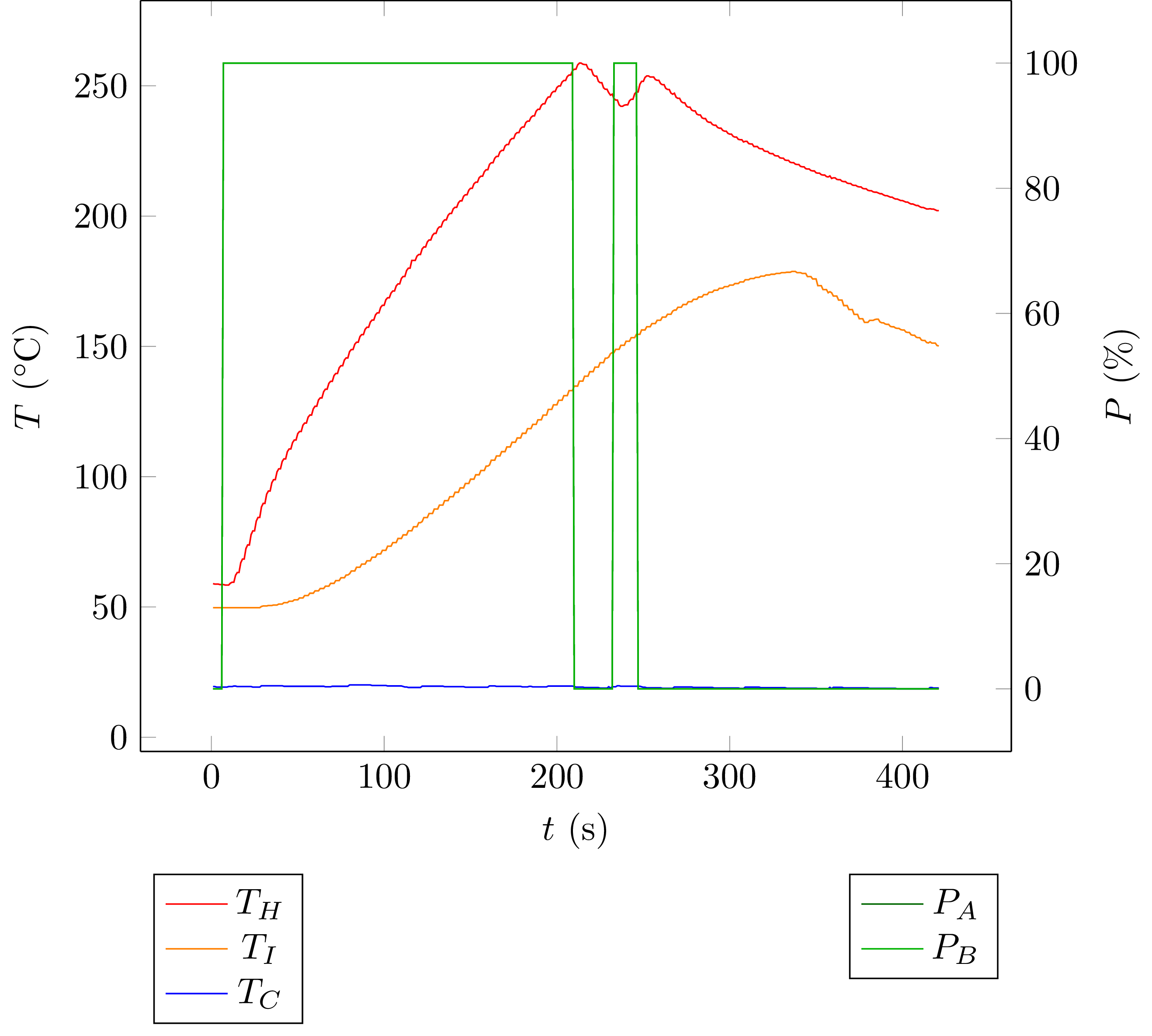

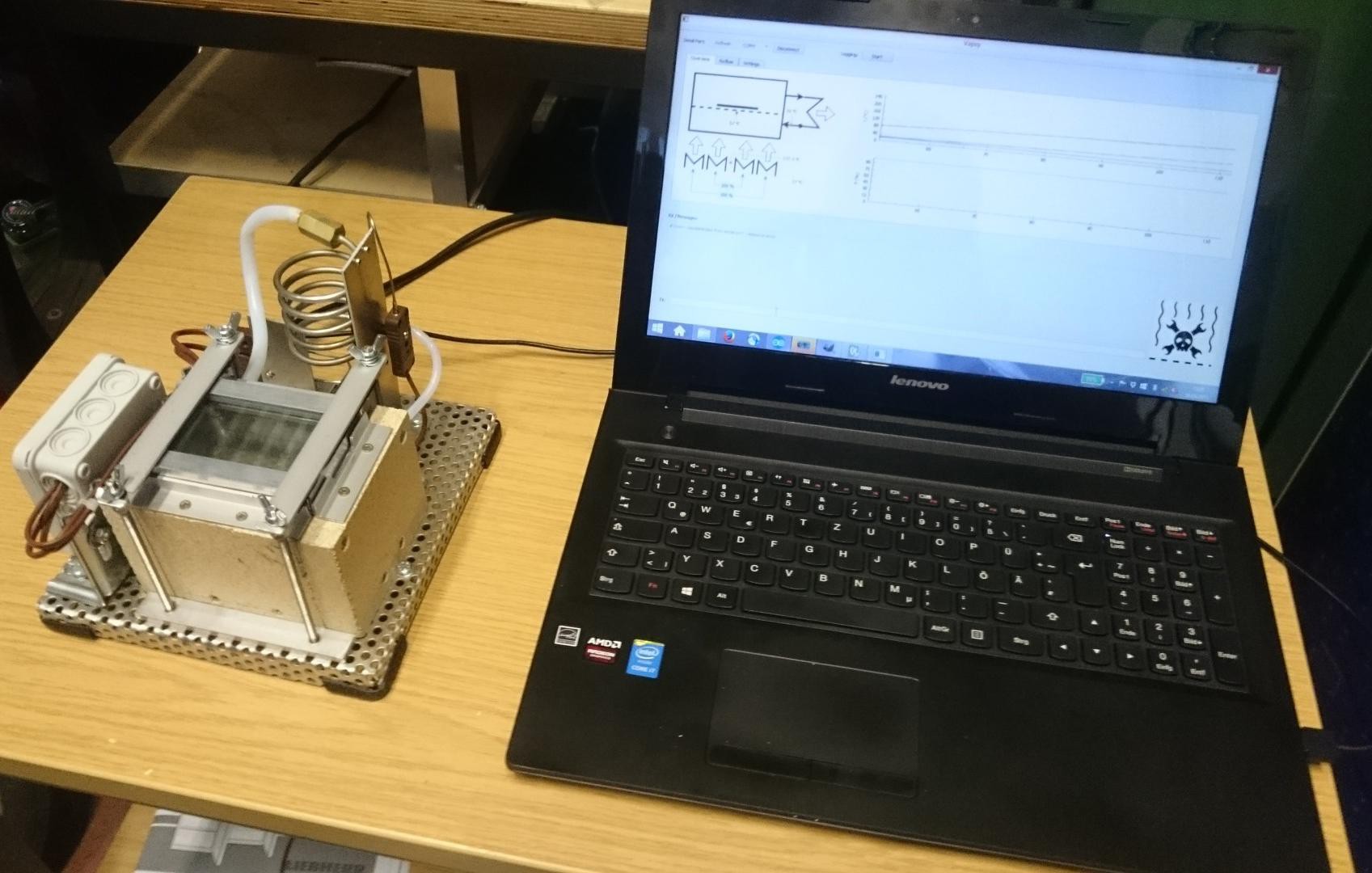

Well, this one was easy. I implemented the overtemperature detection described in the previous log, fired up the heaters at 100% and got this (no galden in the oven):

- The oven was heated to about 60 °C in a previous run.

- It correctly switches off at about 255 °C (T_H, red plot, thermocouple close to the heaters)

- and back on again at 245 °C.

- Auto-off again at t = 250 s. I then manually set the desired power to 0%.

- The whole region around the heaters heats up quite quickly at about 1 K/s.

- Cooldown is slow. Really slow. Like a dead snail.

- Smoke came out from the gap between the aluminium chamber and the thermal insulation, and from the pressure compensation pipe. I don't know why, maybe 255 °C were jusst a bit too much for some component.

As a consequence to the smoke I lowered the overtemperature thresholds to 245 °C (off) and 240 °C (on). Going lower than that is probably not feasible because the galden evaporates at 230 °C and some margin is needed to actually get heat into the boiling galden.

I don't know where the kink in the T_I (chamber thermocouple) comes from.

With Galden filled in

First of all, yes it does!

But getting there was at least partway dangerous because I turned vapsy into a galden geyser for a moment. Here's what I did:

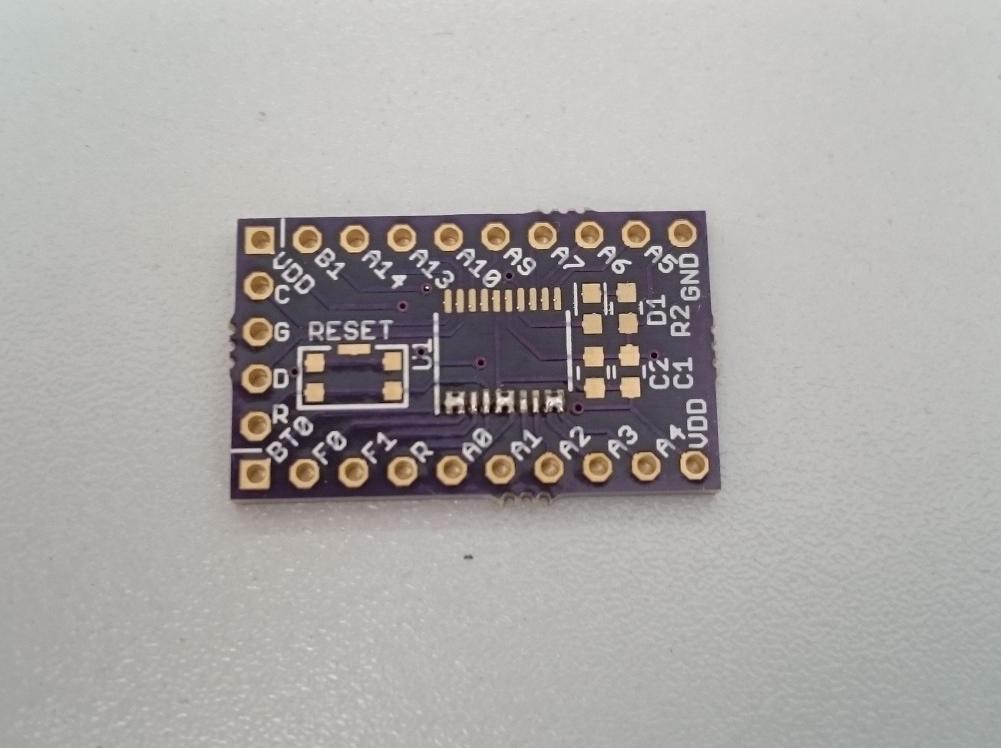

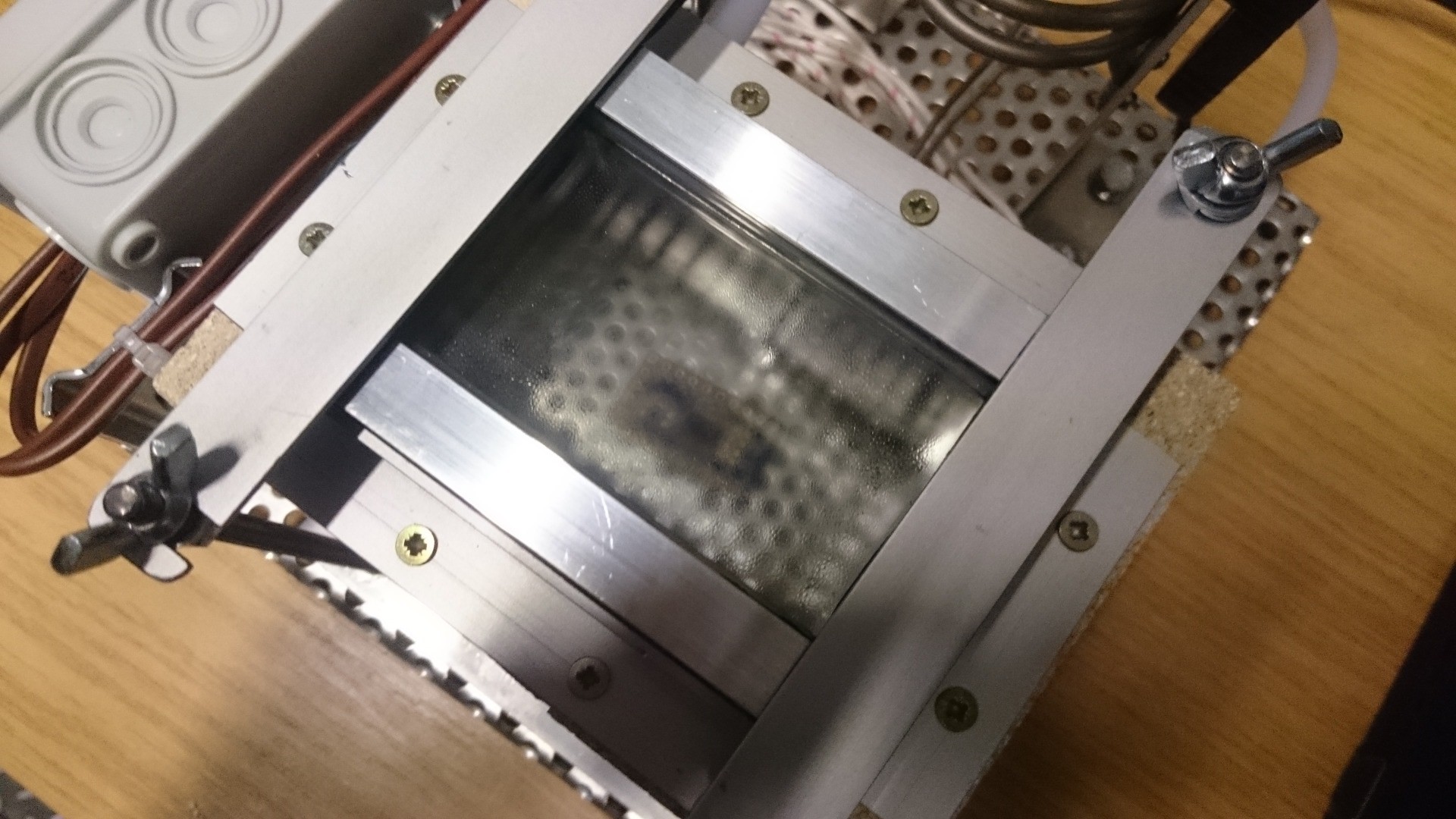

of the PCB in the chamber:

Heaters at 100% (that's 400 W):

and after a while small drops of galden condensed at the lid's inner glass plate:

These drops grew with increasing steam quality in the chamber. When the chamber was filled with saturated steam, steam also exited through the chiller. This is when things got dangerous, because the power was still set to 100 %.

- After a short while galden vapor came out of the pressure compensation tube

- After another short while, liquid galden was pushed out

- I quickly set the power to 0, which the oven quickly reacted to by releasing no more galden.

What happened? My guess is that galden bubbles entered the chiller from below, pushing liquid galden out of the tube. This was most probably caused by the high heat flux, which was

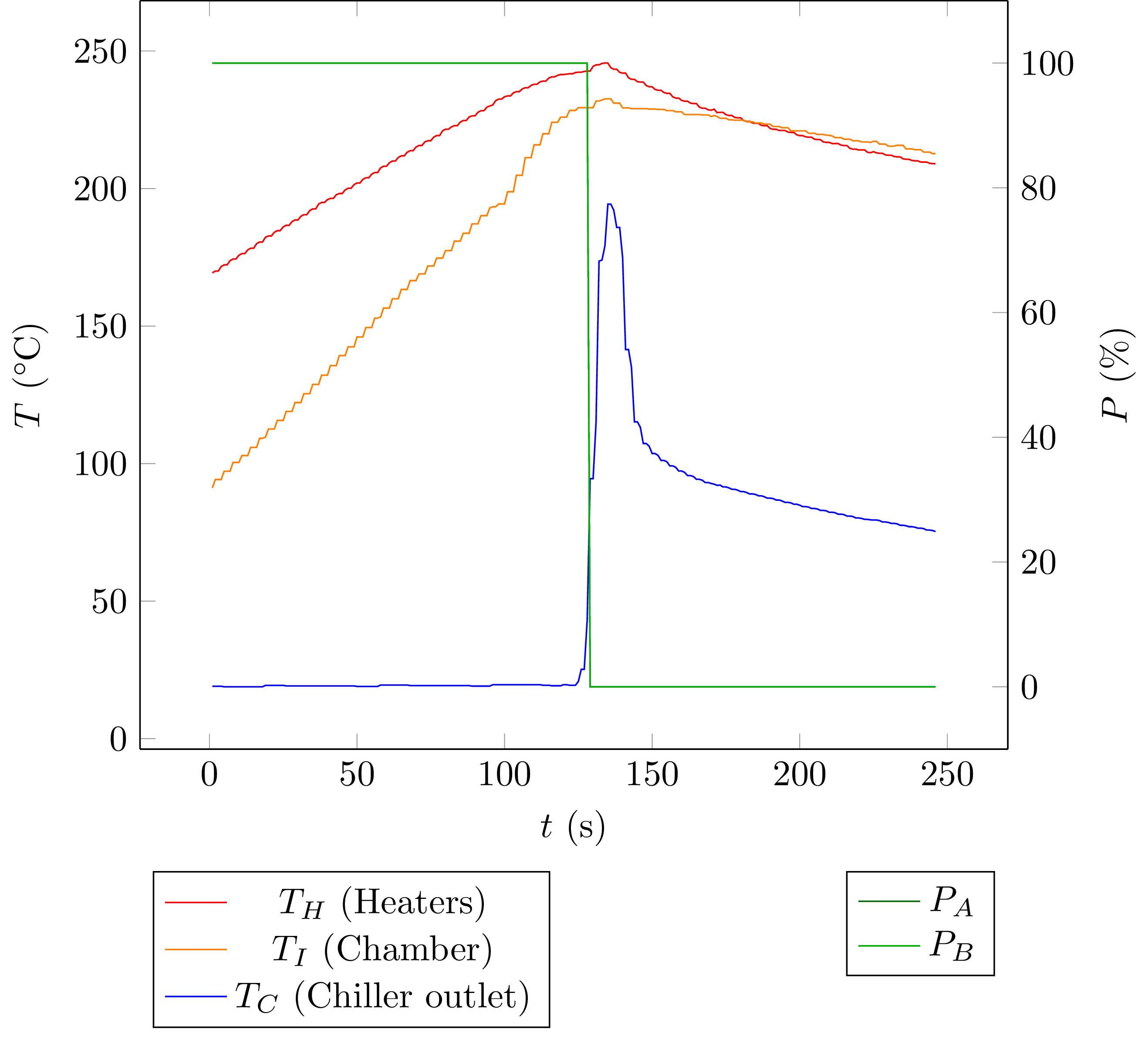

Here is a plot extracted from the logs:

Let's start with the region t < 100 s: Both heaters and chamber heat up, the heaters are significantly warmer than the chamber. Nothing surprising here really.

t = 100 s: galden starts to evaporate. The boiling point is given at 230 °C, and looking at the raw data reveals that the heaters have roughly this temperature at that time. The evaporated galden brings a lot of heat into the chamber, which now heats up quicker than before (how cool is that!?) until it reaches 230 °C as well. Overtemperature protection doesn't kick in because the galden does a good job at cooling the heaters.

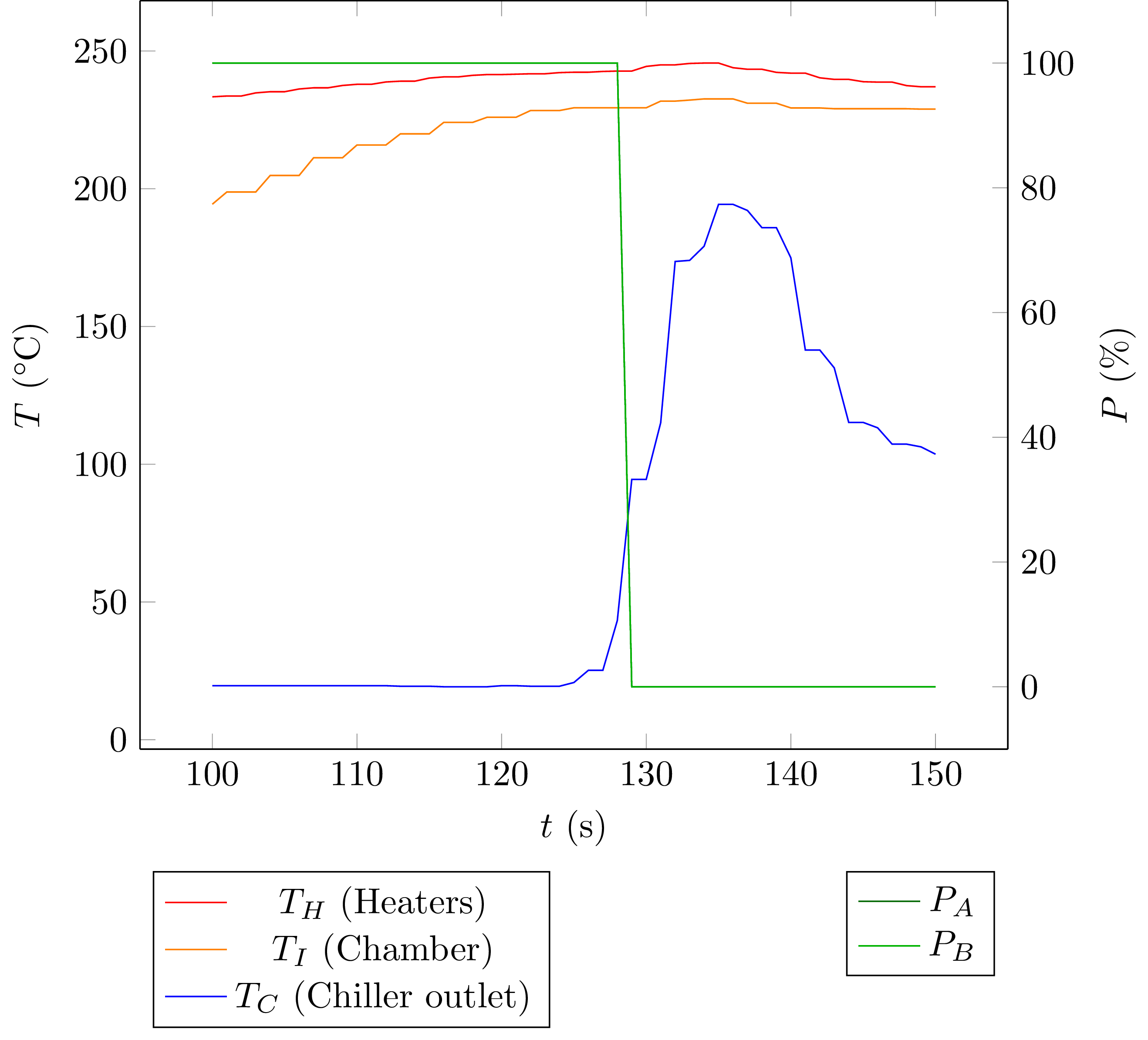

So up to t = 120 s or so nothing happens in the chiller, which quietly waits for something to be done, at about 20 °C. Now things get interesting and here's a zoomed in excerpt:

As soon as the chamber is saturated with galden vapor (t = 125 s), the chiller outlet temperature increases because the chiller now has to cool down a certain amount of galden per time. The theoretical maximum with a vaporization heat of 63J/g would be

assuming that there are no heat losses to the ambient. That's quite a lot and this small chiller certainly can't handle it:

- The chiller exit temperature rises rapidly (t = 130 s, T_C = 94 °C),

- until saturated galden reaches the exit, causing another increase in temperature (t = 133 s, T_C = 173 °C) because the vapor condenses in the massive fitting which also holds the thermocouple. Galden vapor exits through the pressure compensation pipe.

- Now liquid galden is pushed in by bubbles from below (t = 135 s, T_C = 194 °C), which has a higher heat capacity per volume than the vapor. Geyser mode!

The chamber temperature remains constant at about 232 °C. This tells me that the thermocouples are exact enough for this job (I haven't calibrated them).

Consequences

First of all, I won't switch this thing on again until I a have better control strategy. Full power is no strategy at all, so it can only improve! I'll need to think about ways to reliably keep the chiller within its limits. Another overtemperature detection for T_C would certainly work, but there are certainly "softer" ways of getting this right.

Christoph

Christoph

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Are you sure? yes | no

My setup is just what you describe, but with a very small overflow chamber.

Are you sure? yes | no

Are you sure? yes | no

Are you sure? yes | no

So did you basically make a coffee maker pump that pumps Galden out of your pressure compensation opening? http://www.engineerguy.com/videos/video-coffee-maker.htm

Are you sure? yes | no

yes that's one way how things can go wrong. I'm sure I can circumvent that mode, though

Are you sure? yes | no

Are you sure? yes | no

yes, the lower one is submerged. I didn't think of the coffee maker when I decided to place it there...

Are you sure? yes | no

Also submerging the lower tube was done on purpose, so that vapor can't enter it and escape through the pressure compensation pipe. At least that's what I wanted to happen/not happen.

Are you sure? yes | no