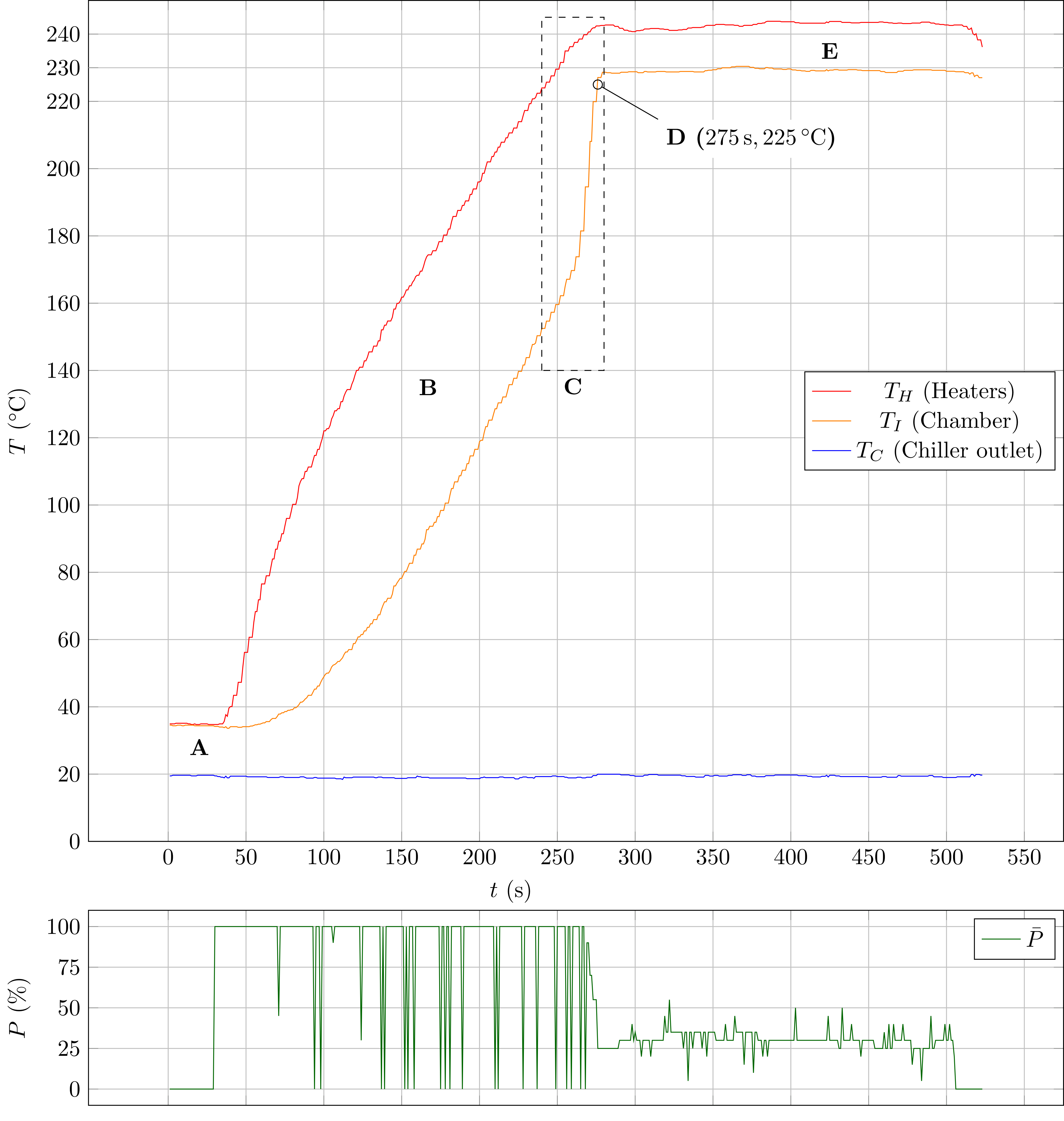

After some bug fixing in my controller code and retuning, I got this plot of a heat up phase and some time in "evaporate some galden" mode:

A) Oven starts slighty warm at about 35 °C, because it didn't cool down completely from the previous run. Things start at t = 30 s.

B) Heating up the chamber to 225 °C before switching to evporate mode in the region marked as "C".

C) When the heaters reach 230 °C, galden starts to evaporate at the chamber's bottom, drastically increasing the heat transfer rate. The galden vapor pushes out the air from the chamber until it is filled with saturated vapor. The chamber temperature then doesn't get above 230 °C as long as there is liquid galden at the bottom.

D) The chamber reaches 225 °C and the controller switches to evaporate mode.

E) A pretty much constant flow of galden is evaporated and cooled down in the chiller (I could see galden bubbling up the chiller inlet tube). The chiller outlet temperature doesn't rise, though, because the mass flow rate is very low. The heaters are kept at 243 °C.

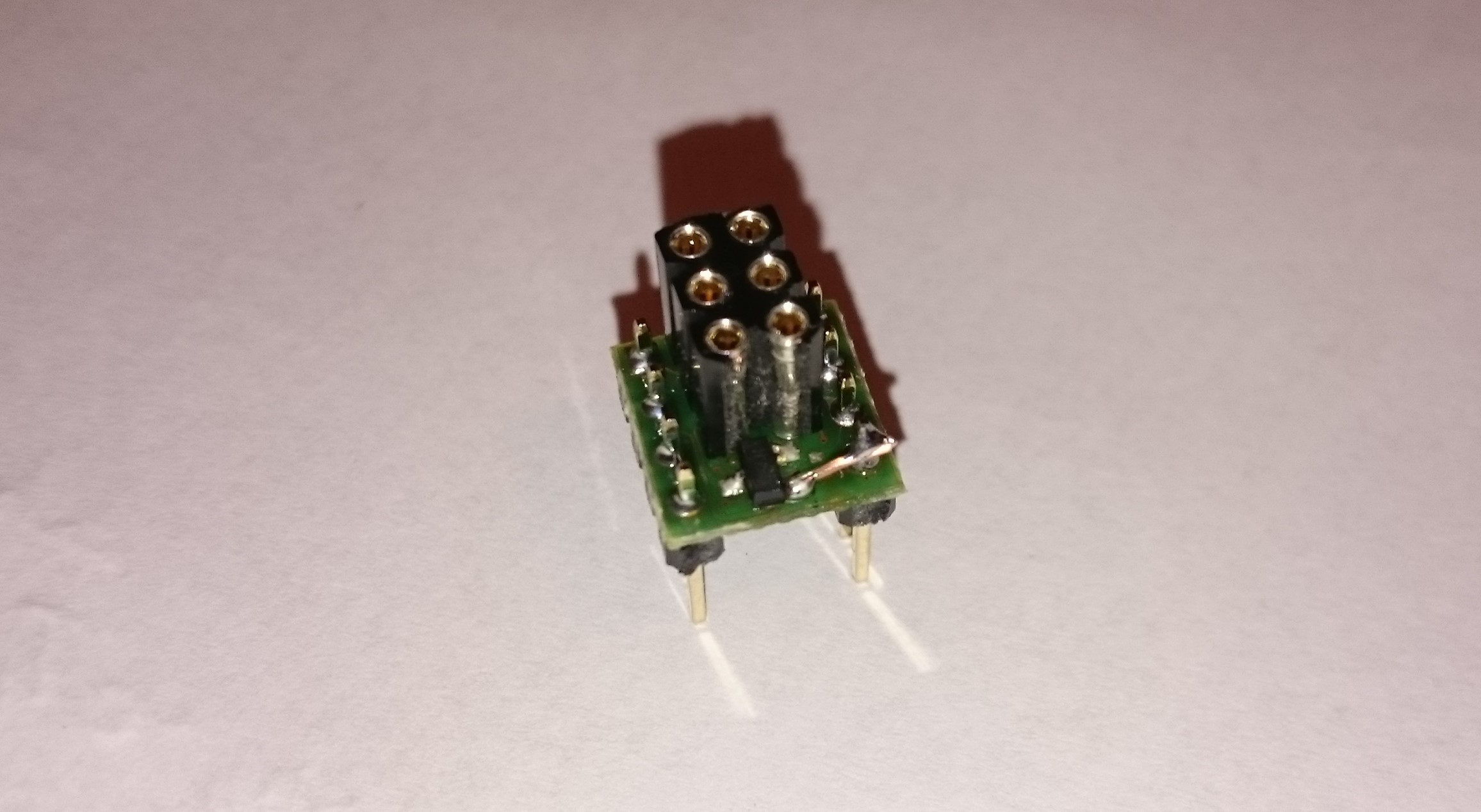

So I tried to solder a #DIPSY which worked out quite well (it seems):

I could measure a resistance of some 16...20 MOhm between all pins and ground or supply.

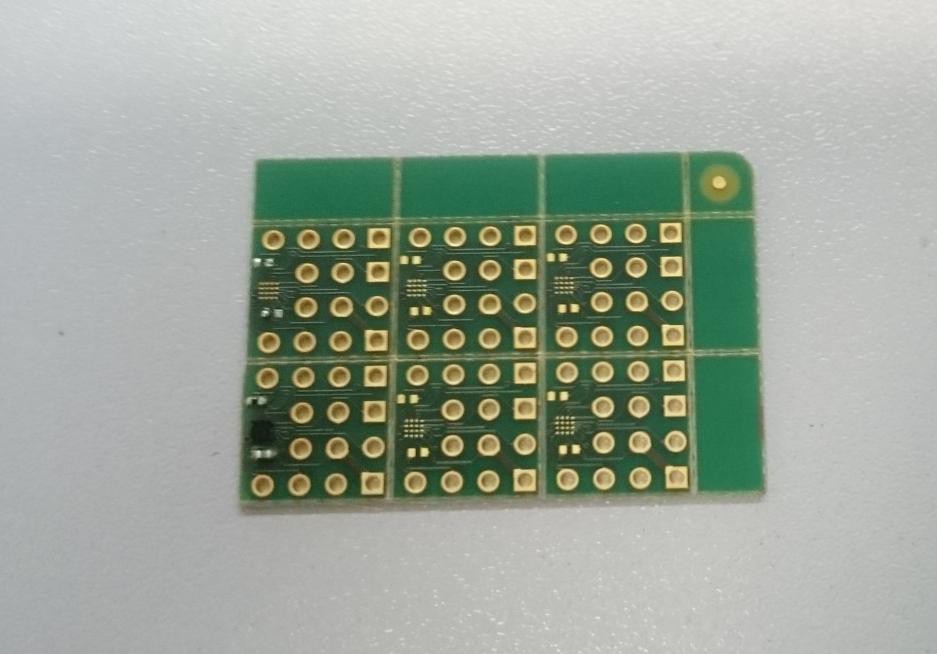

One problem was the bottom side which I assembled manually, and I ripped off one trace while soldering the capacitor. It was possible to replace it with a piece of wire:

Christoph

Christoph

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.