I've been doing some reading up on how to CNC, and I think I've figured out why the end mill from my first tests went blunt. I was worried about breaking the end mill or the CNC machine by running the Dremel too slow so I had it on max speed. It turns out though that the Dremel runs very fast for a typical CNC machine, and when you spin the end mill too fast it heats up more as it cuts. When it heats up too much the metal gets buggered up and goes blunt very fast. As a result for future tests I plan to run the Dremel on the slowest setting, and program in frequent breaks to give the end mill a break in which to cool down.

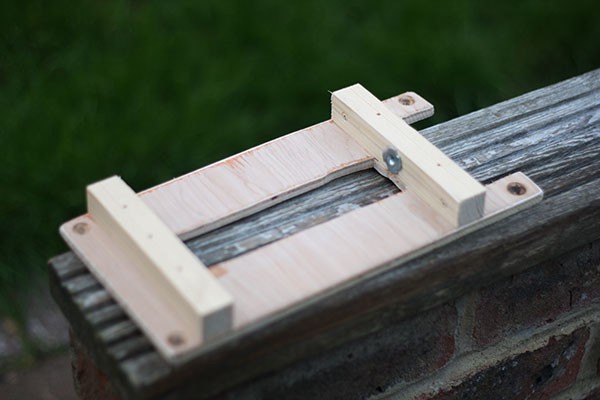

I also made a vice platform to hold the wood more securely as I cut. I started out making a copy of the existing plywood platform, and cutting bits off and screwing bits on:

Then I made a sliding jaw that is held in place by the slot. it has a bit of metal ruler at the bottom as I wasn't sure I'd have enough clearance for a wooden piece.

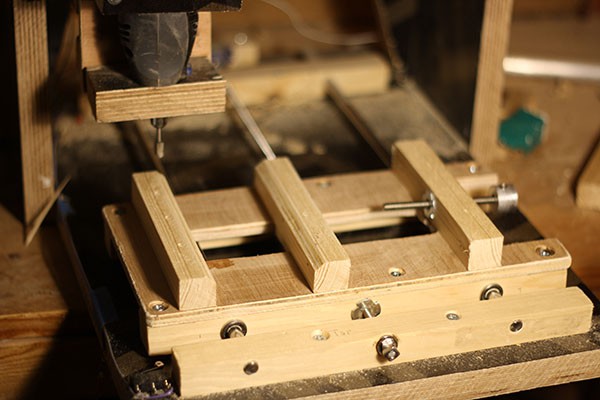

Then I put the two together and added a bit of threaded rod, and fitted it onto the rails:

The threaded rod is short because a long one would interfere with the bed moving back and forth. If I need to cut something small though I can just put a bit of scrap wood between the threaded rod and the jaw. I also cut a bevel into the inner side of the jaws using the CNC machine, which I managed to do without overheating the router bit.

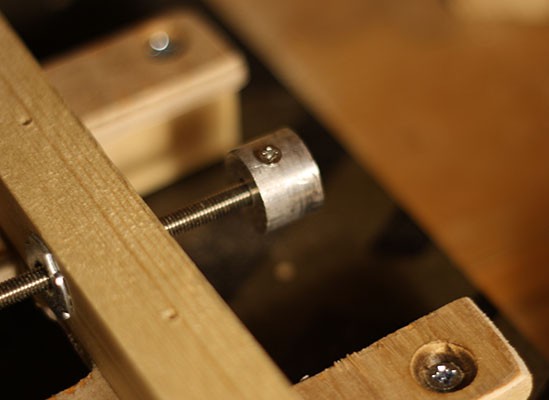

I also made a little knob for the threaded rod with my drill and some scrap aluminium tapped for a screw:

It holds whatever I put in there nice and securely with no wiggle in any direction, success!

penleeki

penleeki

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.