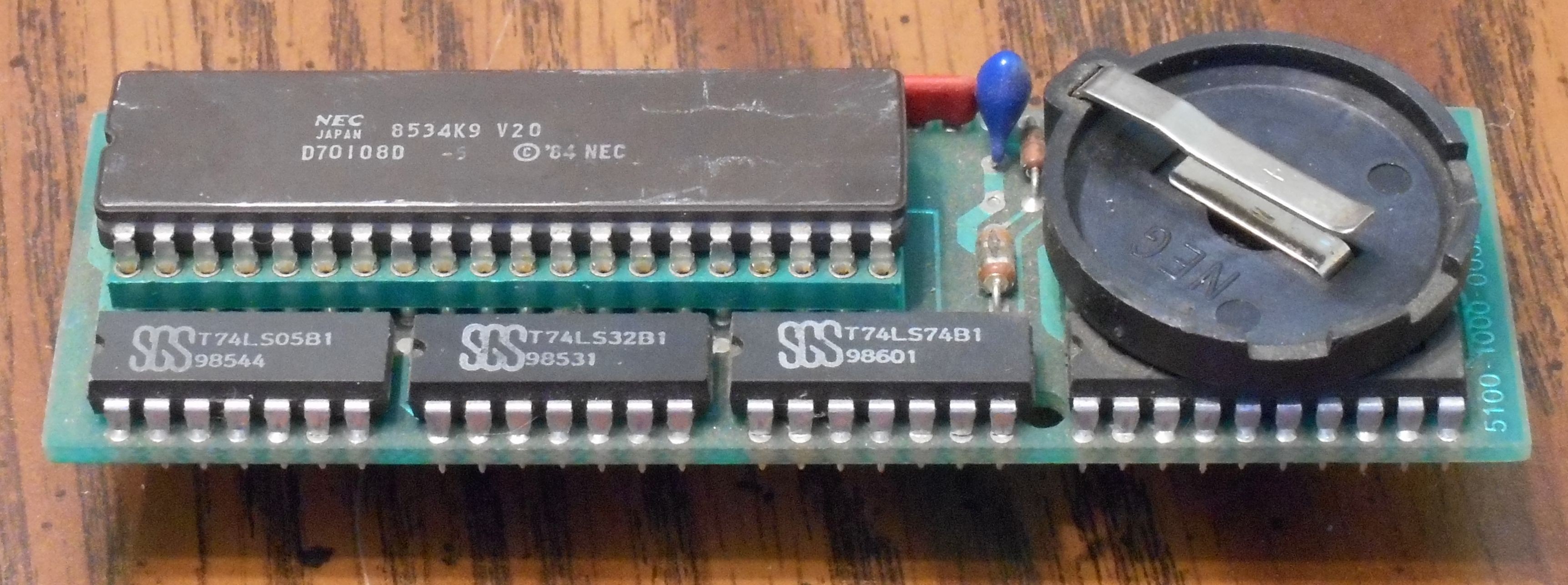

A few weeks ago I was looking around one of my favorite online auction sites, http://www.shopgoodwill.com/ and came across an original Compaq Portable with the high bid at $5. I watched the auction, put in a bid, and won.

So. Long story short? The keyboard didn't work. So I fixed it. This is the story in four acts. I go through all of the trials and tribulations, and then show you how to replicate my results. Hopefully this can teach you something, as well as entertain. I have linked the story in its correct order below. Enjoy!

leadacid44

leadacid44

Dave Collins

Dave Collins

David H. Bronke

David H. Bronke

Geek Centric

Geek Centric

Dr. Cockroach

Dr. Cockroach

I literally signed up to congratulate you on your repairs and to say it made for entertaining reading (both the electric car and the compaq keyboard).

I was about to buy a compaq portable but now realize, WTH was I thinking. I don't have the time, expertise or patience to do what you've done with these 2 things.

You see, I was so excited to get an old pentium computer running, I had fleeting psychosis of nostalgia. I am now cured!

Keep up the fight.