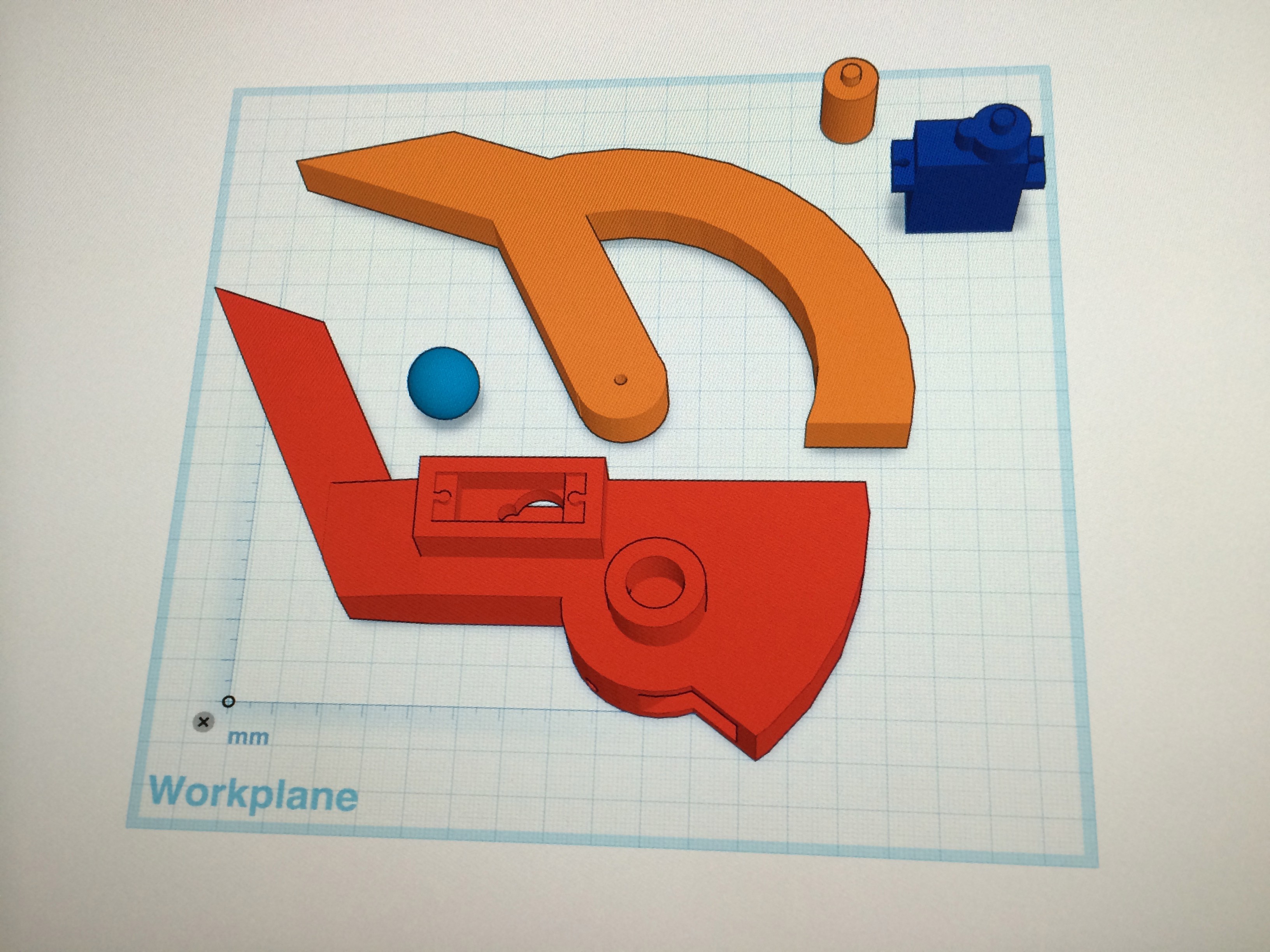

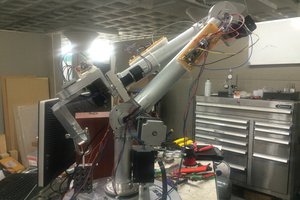

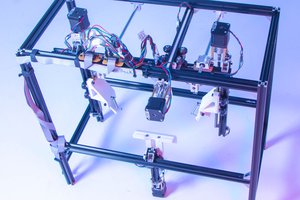

Current status of this project is that the juggling robot is able to juggle 7 balls! I'm pretty sure that is a world record for juggling robots. It can also do some different juggling patterns (i.e. siteswaps), which is also something that has never been done. I plan to fix some issues and make the siteswap patterns more stable, but ultimately my next project will be to create a toss juggling version.

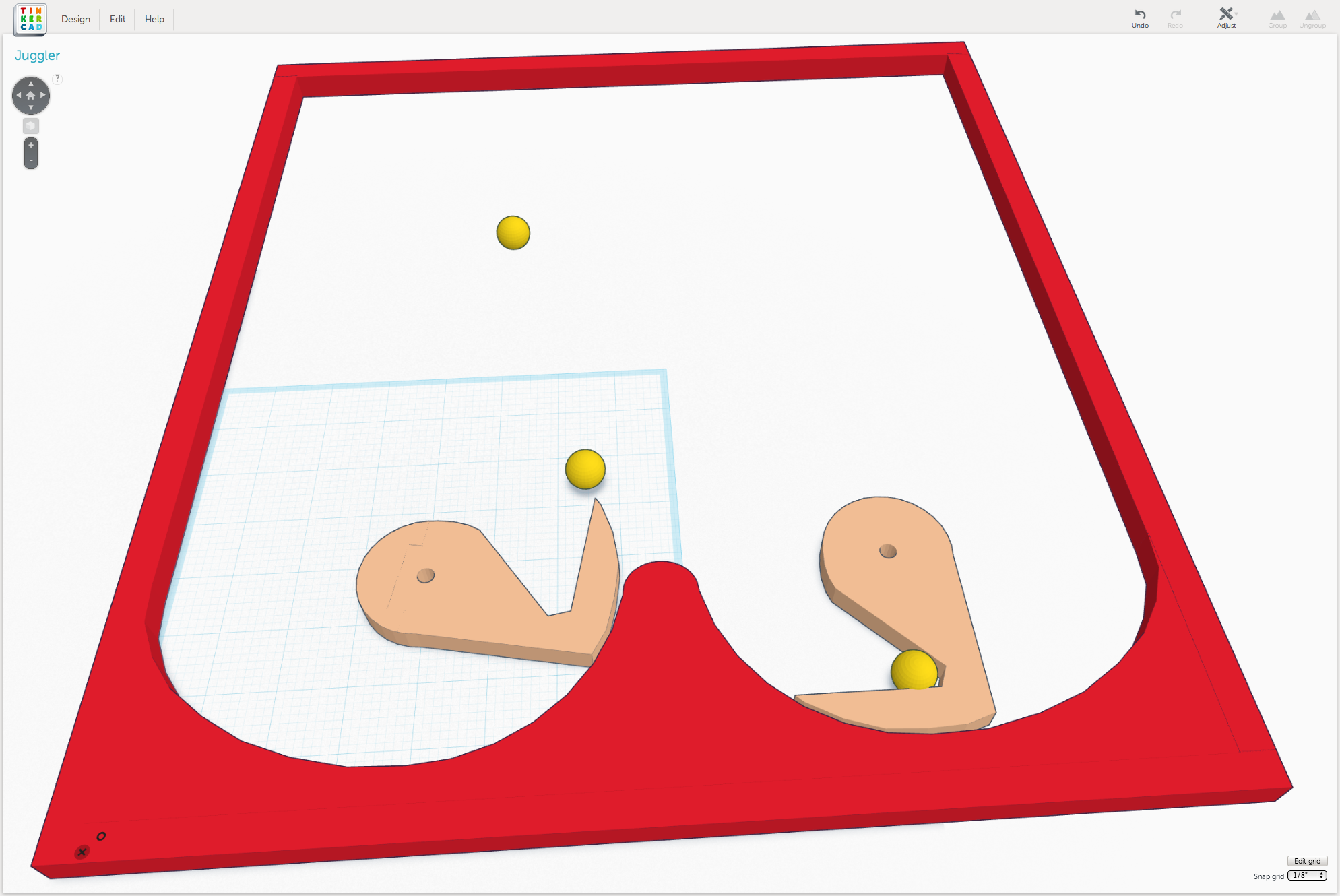

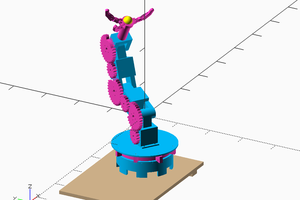

Juggling Robot

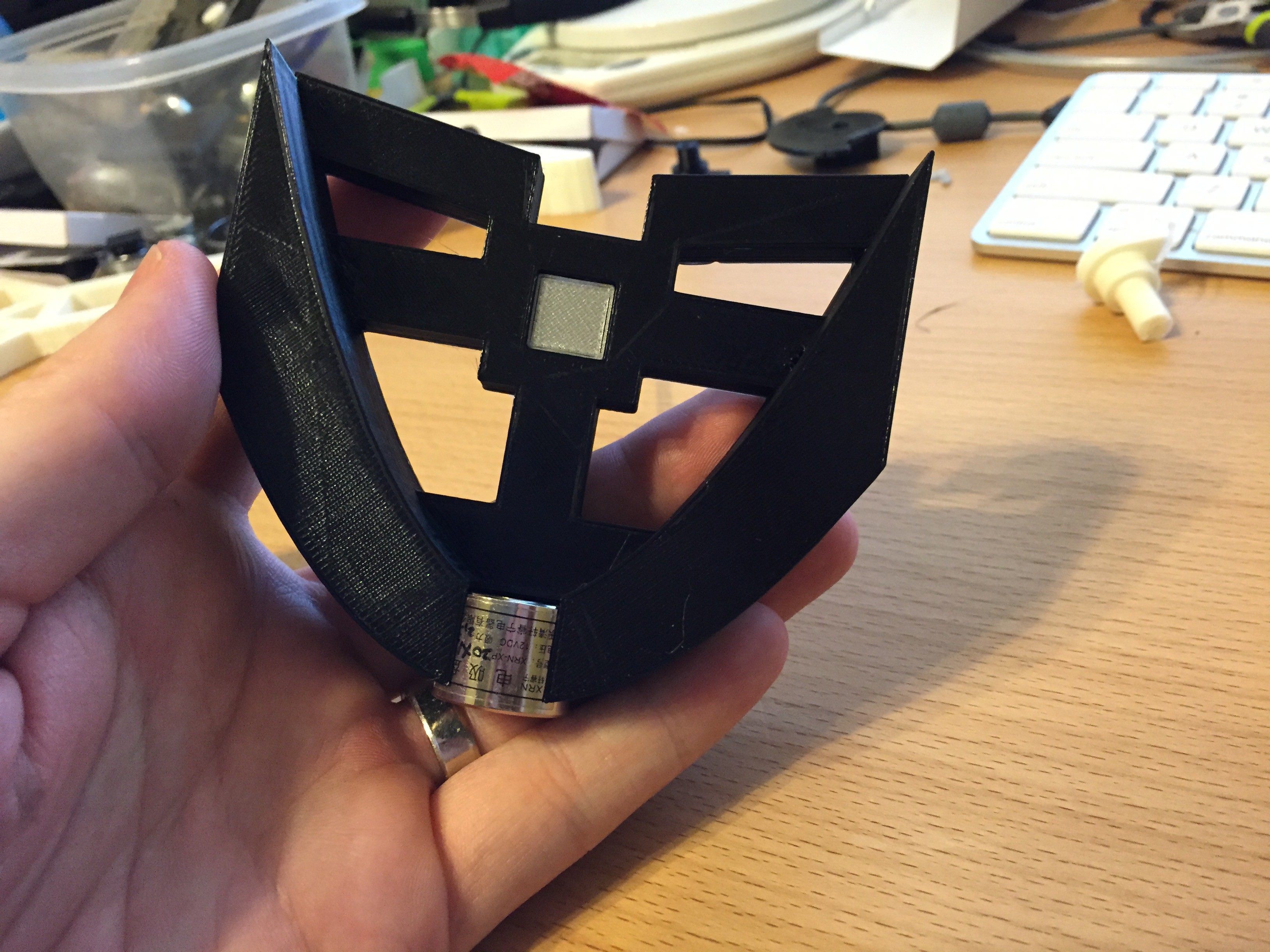

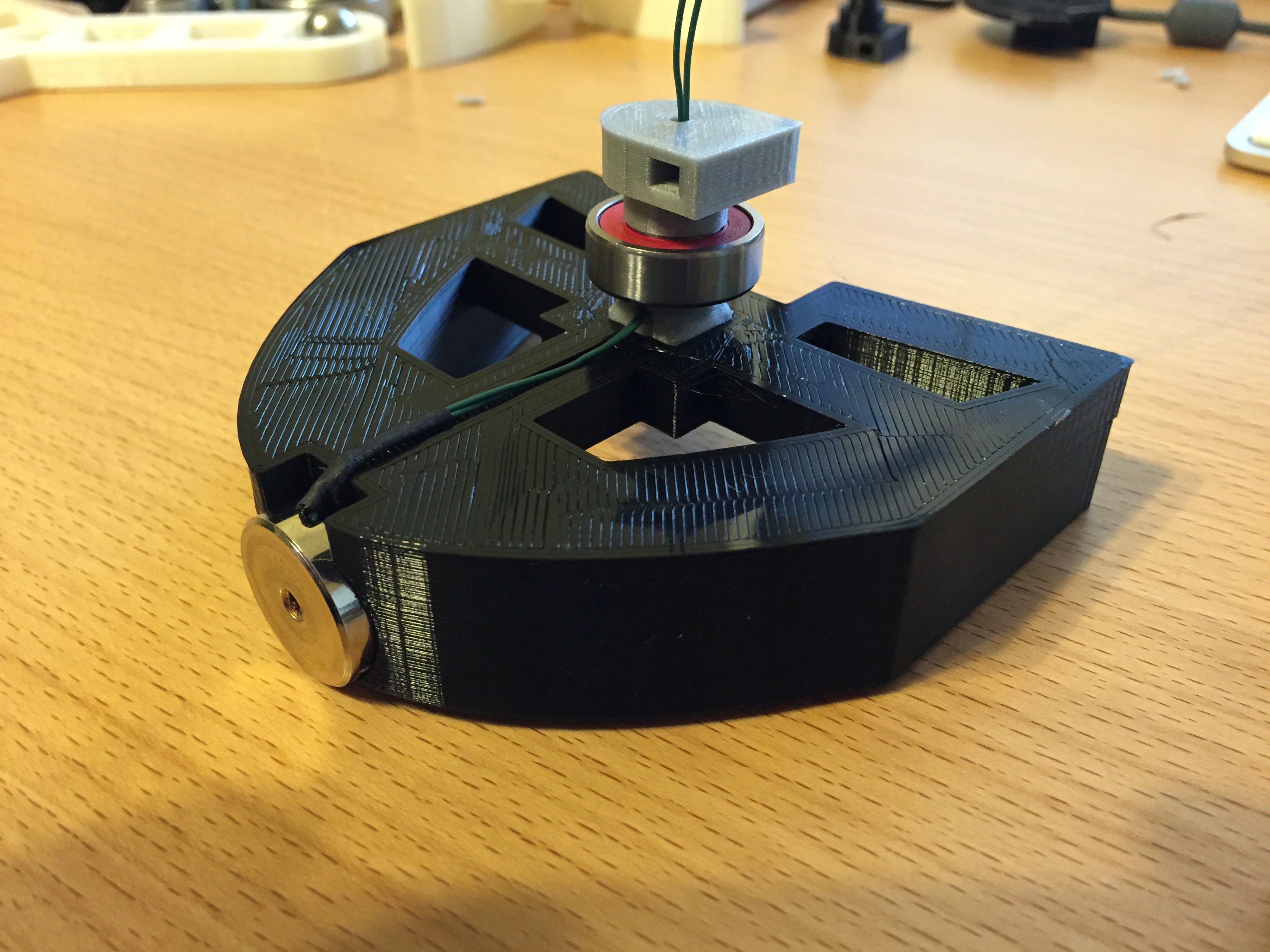

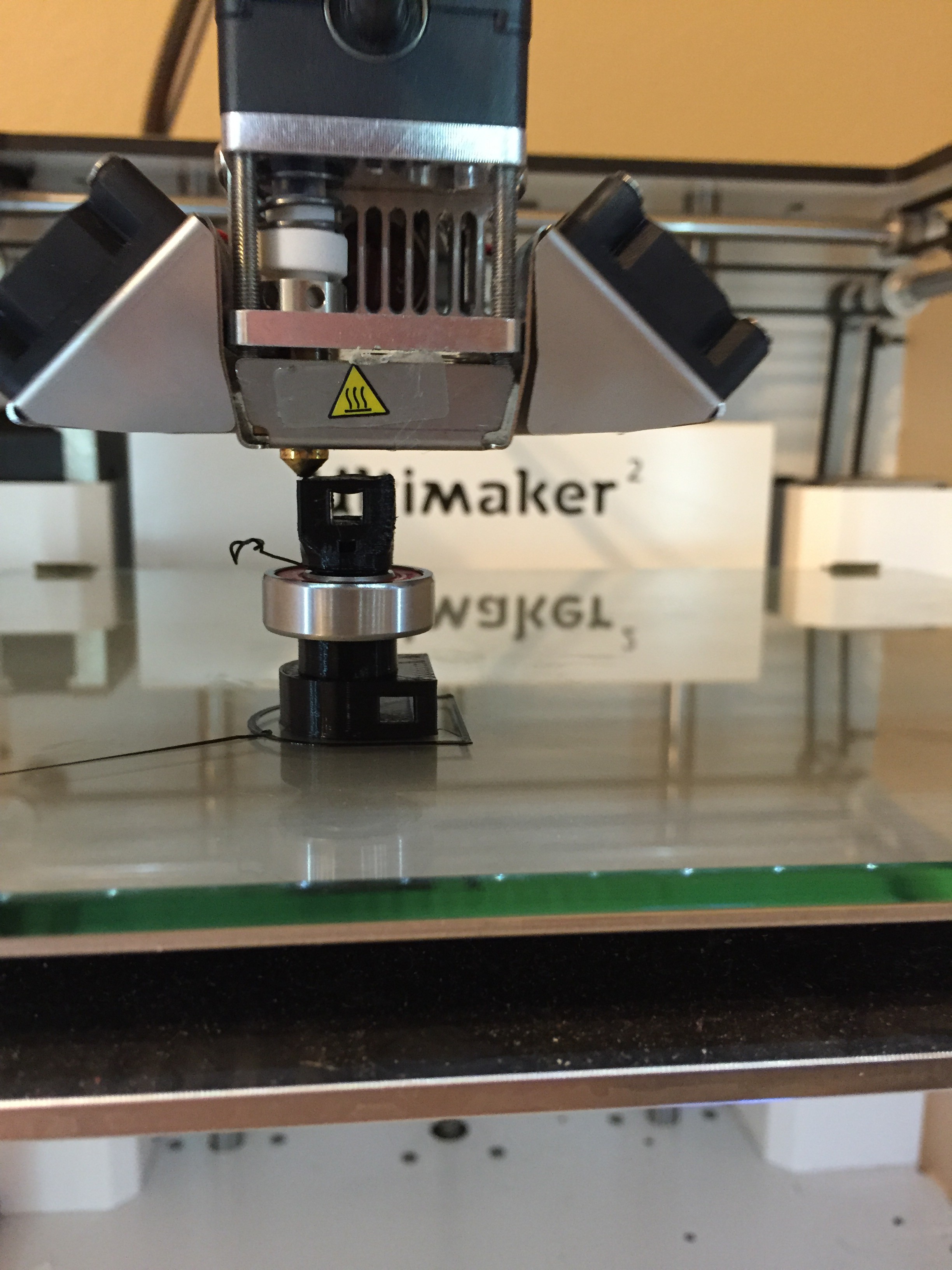

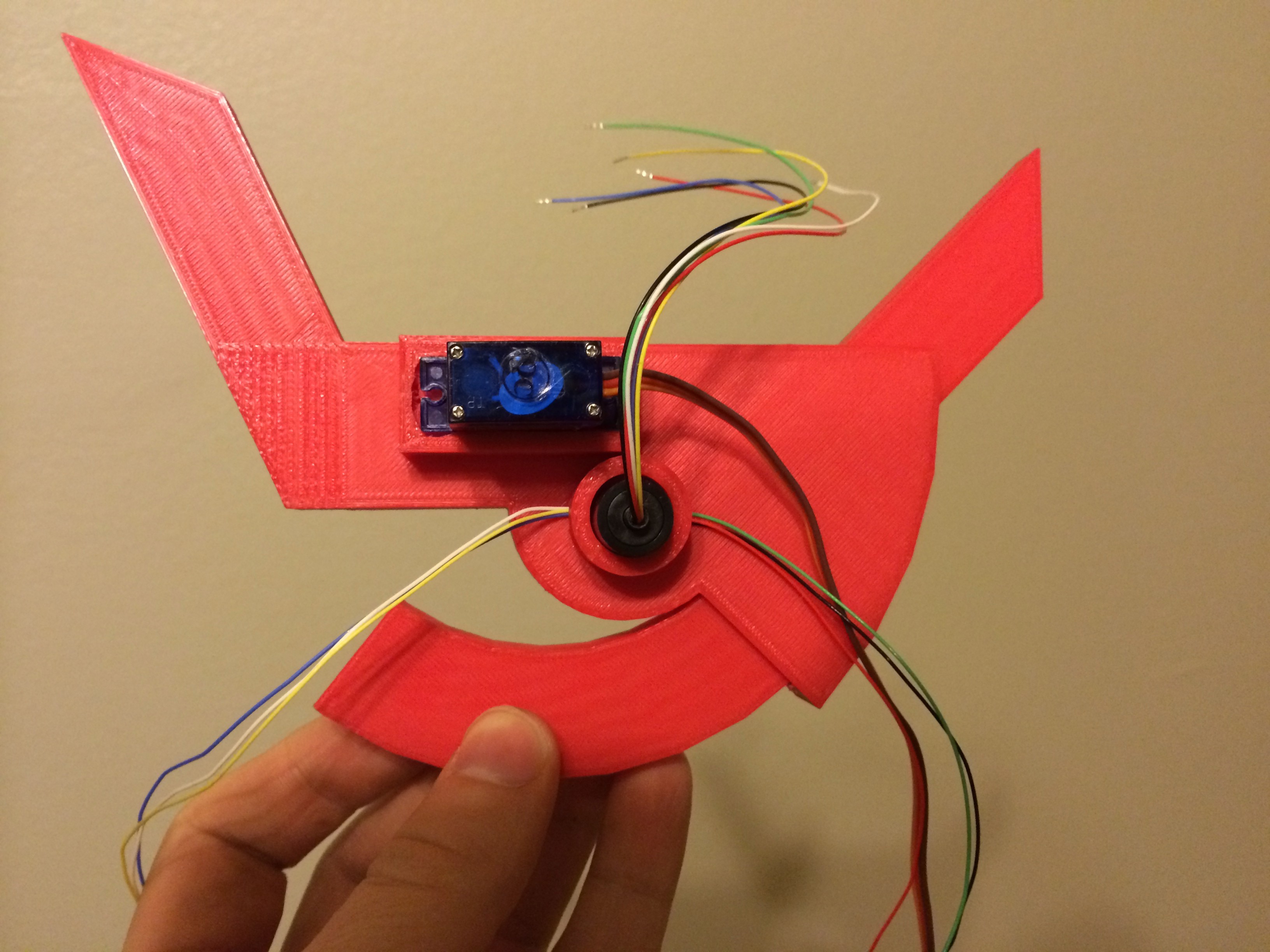

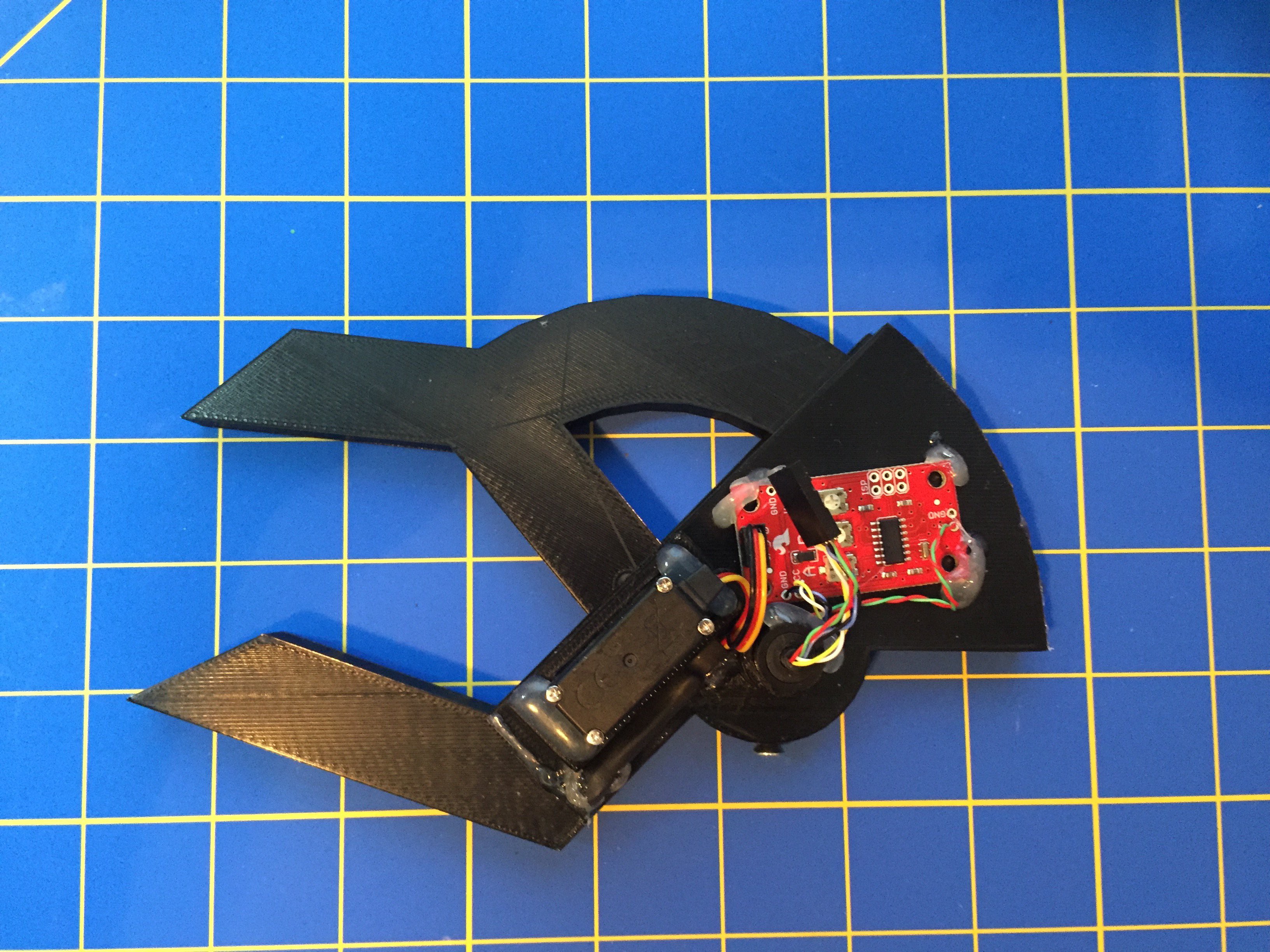

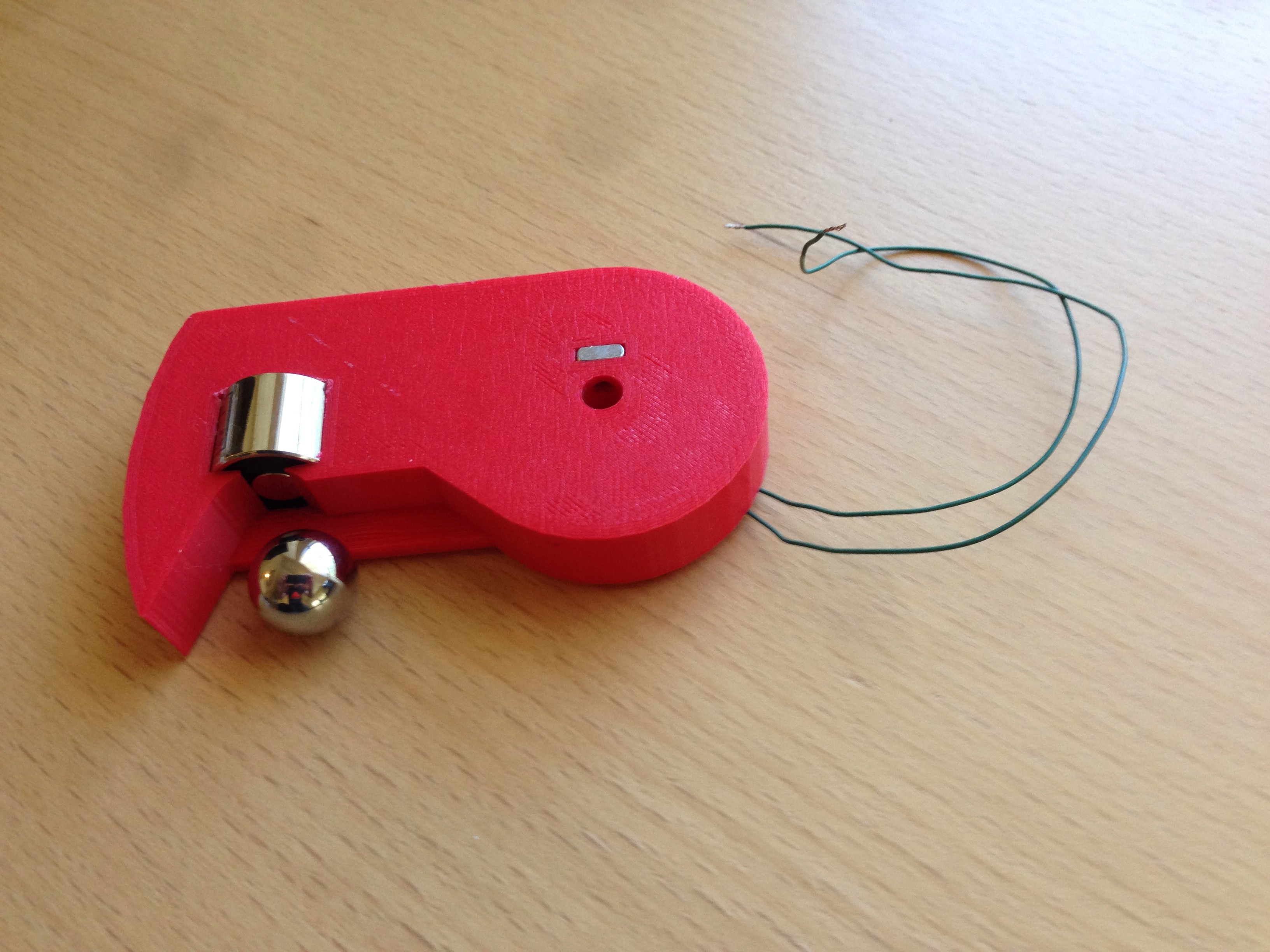

This robot can juggle 7 balls and various juggling patterns by rolling balls on an inclined surface.

Nathan Peterson

Nathan Peterson

Colin Kingsbury

Colin Kingsbury

Les Hall

Les Hall

Sarah Petkus

Sarah Petkus

Nice, mesmerizing. I built a Claude Shannon juggling machine. I know what you mean, took a year and I gave up several times but just had to stick it out - was so gratifying when it worked. Mine is a real hatchet job and can only currently run 40 seconds until dropping a ball. But my motor surges and the whole machine rocks a bit - so can be fixed.

Have you done any work on toss juggling machine?