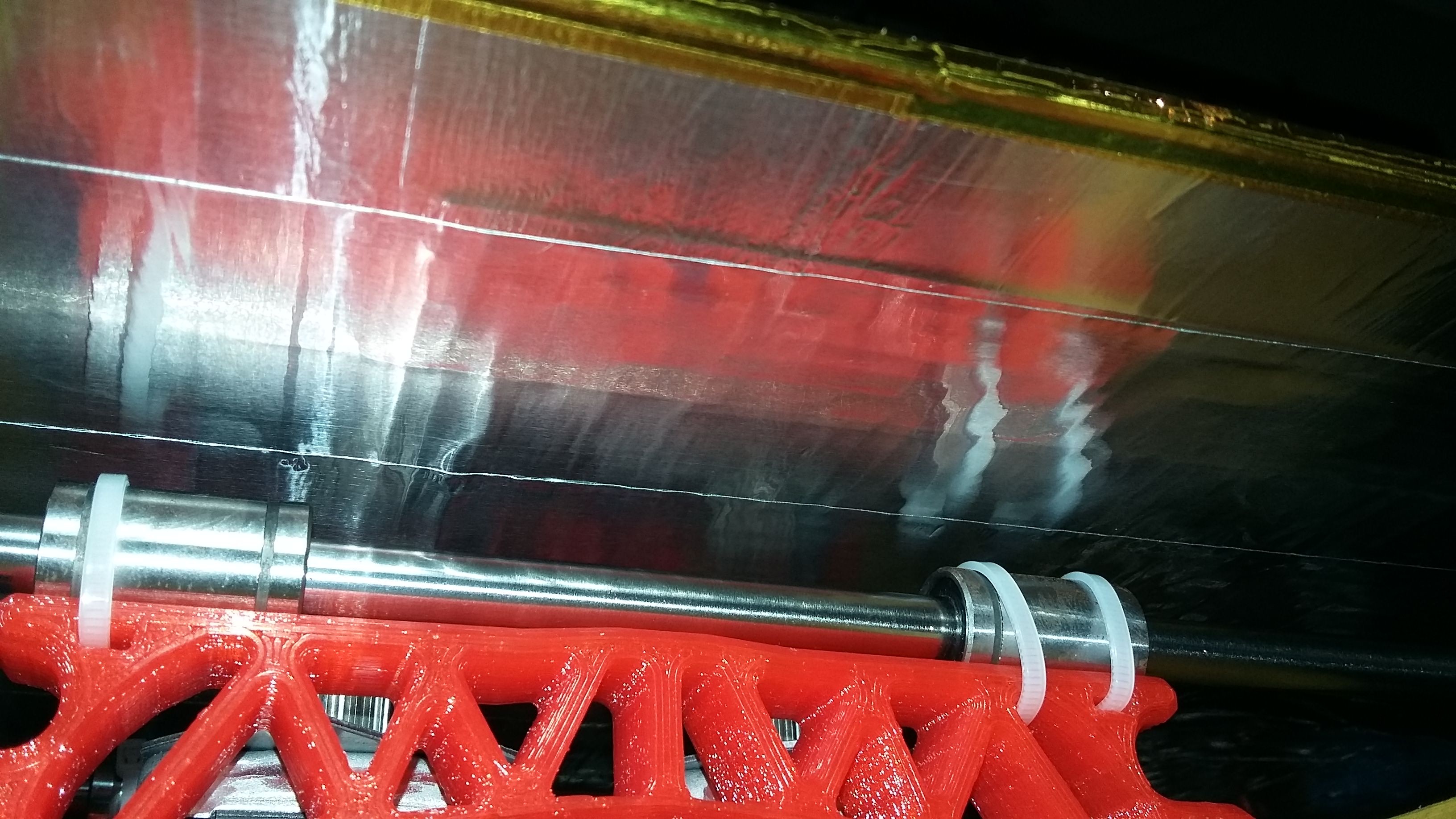

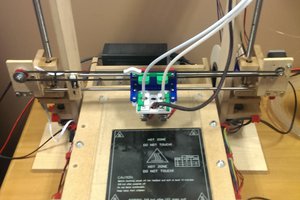

I started by getting 4 old printers from an E-waste company at R50 per printer (± $5 USD) and then completely disassembling those to scavenge for parts.

I managed to get all of the Stepper motors, switches, wiring and most of the linear rods. as well as various shapes and sizes of tactile switches etc.

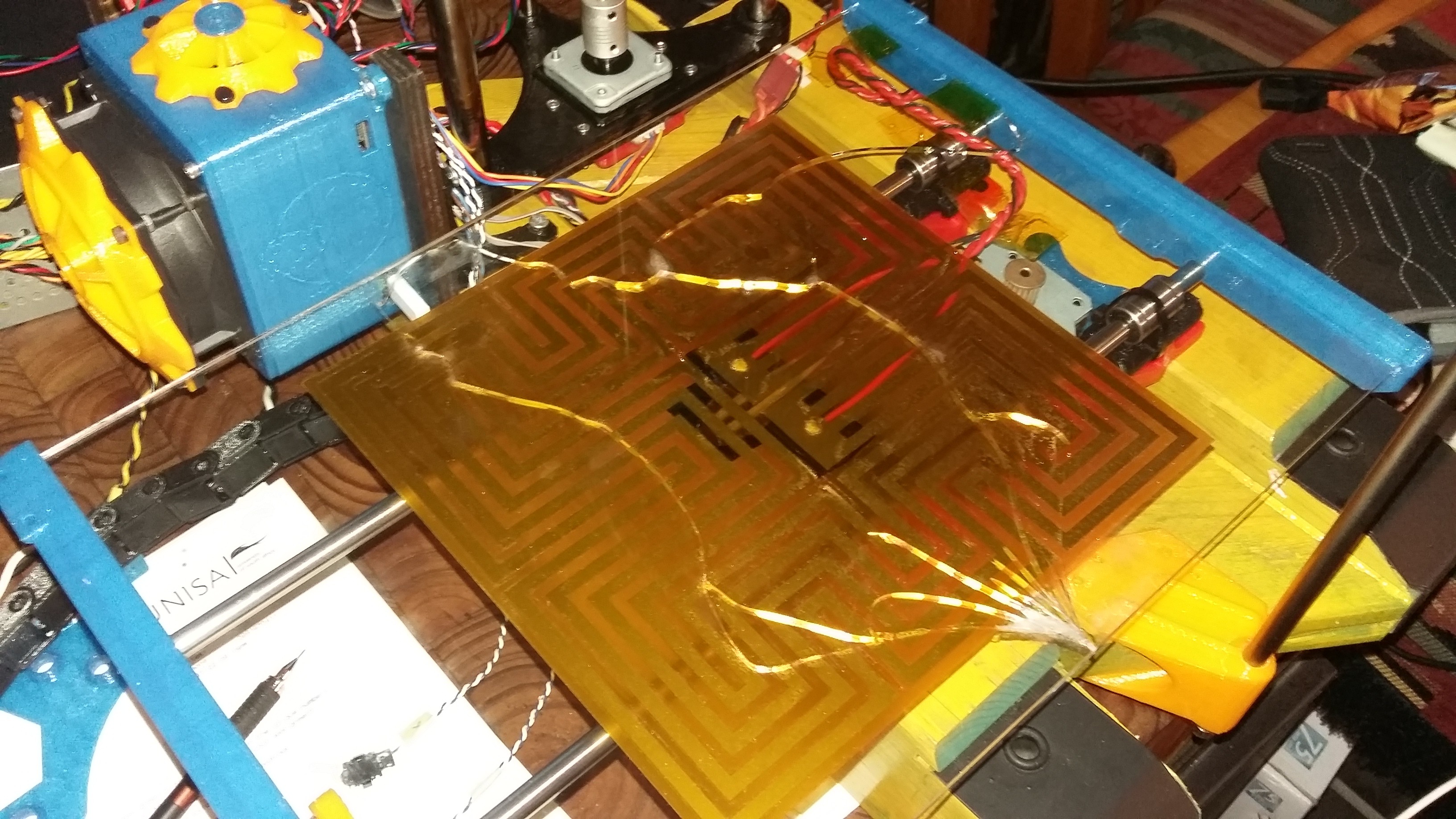

As it stands now I have spent just shy of R3000 (± $200~250 USD) on new parts

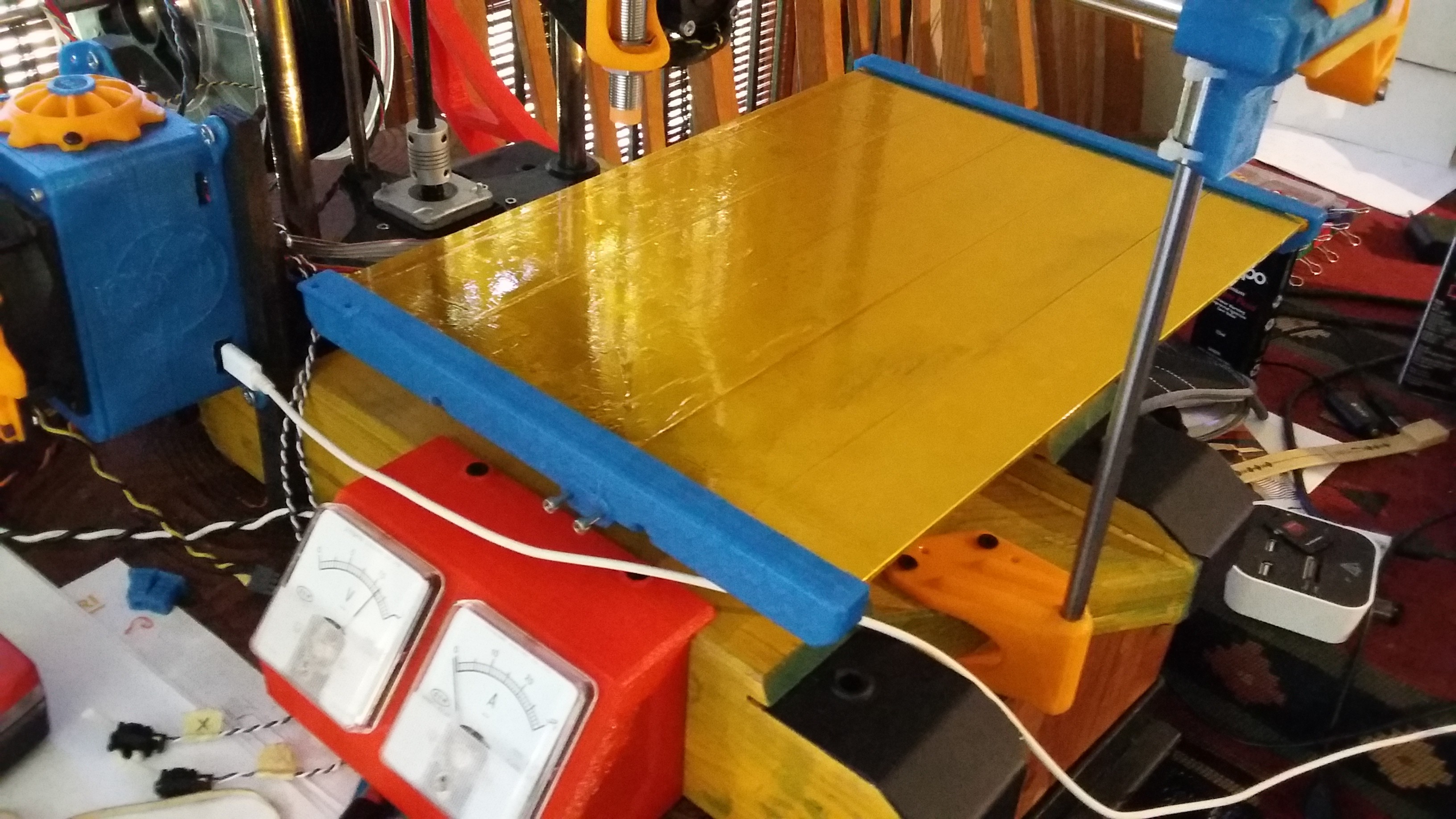

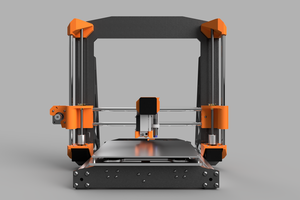

given the print volume of 230×180×250mm I'm quite happy with how things are going so far.

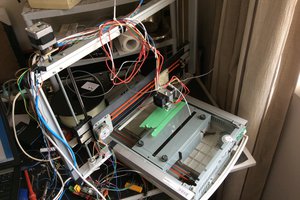

I designed the printer as I built it, while dissassembling old printers, fixing each problem one at a time. It isn't the best design method but hey, "Why not do legwork while you think" - Mark Watney

RenierM

RenierM

Saabman

Saabman

Luke Brandon

Luke Brandon

Terry Bates

Terry Bates

megahercas6

megahercas6