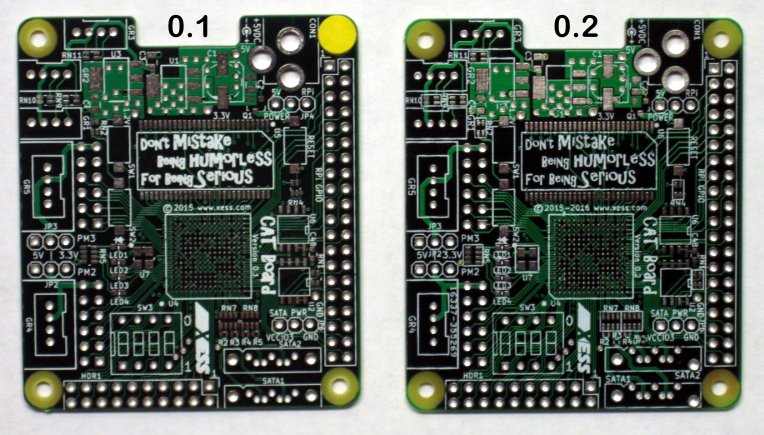

Before assembling a CAT Board with the new 0.2 PCBs from PCBCart, I thought I'd compare them to the previous 0.1 version from PCBWay.

At a macro-level, they both look like circuit boards. No discernible difference. So that's good.

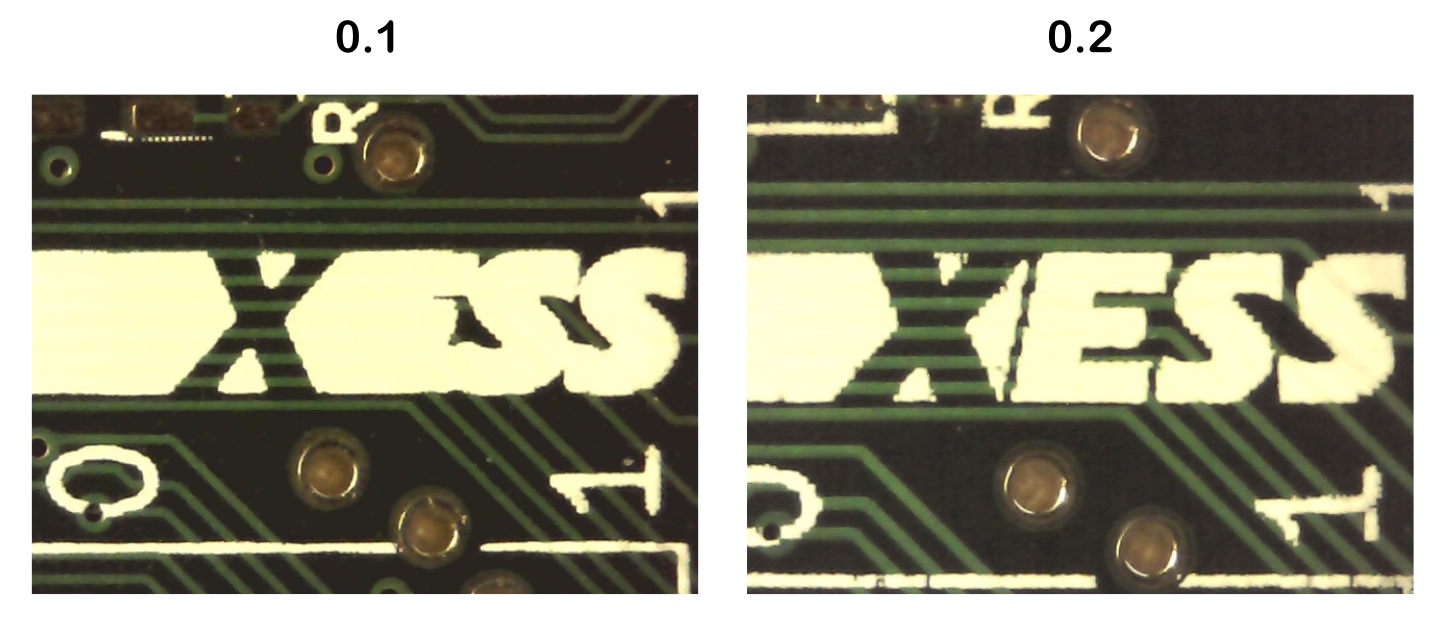

Looking a little more closely, the PCBCart silkscreen is better defined than the one by PCBWay which suffers from some "blooming". But that also makes the part references on the PCBCart PCB look a bit spidery so it's probably a good idea to thicken the text a bit for those.

Now let's look at drill/via alignment. The vast majority of the small 20-mil vias had drill holes punched completely within the copper pad. But there were a few vias in each set of boards that had "breakouts" like those shown below. Thankfully, there were no cases where the drill missed the via completely in either set. For this metric, the PCBWay boards were slightly superior to those from PCBCart but there were no outright failures in either.

The above image also shows the alignment of the soldermask with the BGA pads. Bad alignment can lead to BGA balls not connecting to the pad or having a ball short to a nearby, uncovered via pad. Neither of those is a good thing. The PCBWay boards have a bit more misalignment than those from PCBCart, but not as much overall as the image above would make you believe. Still, for this metric PCBCart has a slight edge.

Another factor to consider is via size. PCBWay can drill holes as small as 8 mils but they require a 6 mil annular pad so the total via diameter is 6 + 8 + 6 = 20 mils. PCBCart drills a larger 10 mil hole but they only need a 4 mil annular pad for a total via size of 18 mils. When you're putting vias between the pads of an 0.8mm BGA and then trying to squeeze traces between them, that extra 2-mil clearance is a big advantage. Of course, the smaller pad size will also lead to more of the drill breakouts we saw above.

Regarding price, I got 11 PCBs from PCBWay for $185 and 10 PCBs from PCBCart for $166. So the per-board price is about the same. But this changes all the time, so always check before submitting a board.

Now I'm on to building some CAT Boards using the new PCBCart PCBs. That will be the true test.

Dave Vandenbout

Dave Vandenbout

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

you maybe interested in utsource.net

Are you sure? yes | no

Hi, Annabel. Getting the silkscreen to look just right is always a matter of trial and error on my part. Your layer registration is a bit better, but you had a few more drill holes breaking out of the via pads. Neither of these appear to be important issues for the prototypes. Overall, I'm quite happy with the PCB quality considering the low price for having them made. Five years ago it would have been impossible to get boards with specs like that in a week for less than a couple of thousand dollars.

Are you sure? yes | no

Thanks for your message. I agree with the drill holes issue and we should definitely pay more attention on this in future days. I'm happy to know that you're satisfied with the board quality at this price. BTW, do you need the discount I mentioned in previous message? If you do, I shall email it to you.

Have a great weekend!

Are you sure? yes | no

Sure, please send the discount but I probably can't use it immediately.

Are you sure? yes | no

Great. I just sent you the coupon using a private message.

Cheers!

Are you sure? yes | no

Thanks!

Are you sure? yes | no

With pleasure. We look forward to serve you with much more advanced boards soon.

Are you sure? yes | no

Hi Dave,

This is Annabel from PCBCart. We're glad to know that you booked PCB services from us. Thanks for the unbiased review.

I agree with the silkscreen issue, we can definitely make it much better if you could thicken the text a bit. When comes to the BGA issue, it seems our registration precision rate is a little bit higher comparing with the 0.1 image. Anyway, we noticed there's still room for improvement. We look forward to your next order and will work harder to perfect your boards. As a gift for sharing your comments on our services, we'd like to offer you a discount. Email me if you want this offer.

If you need any assistance on assembly, kindly reach us at sales@pcbcart.com. We're happy to help.

Sincerely,

Annabel Hou

annabelh@generalcircuits.com

PCBCart.com

Are you sure? yes | no