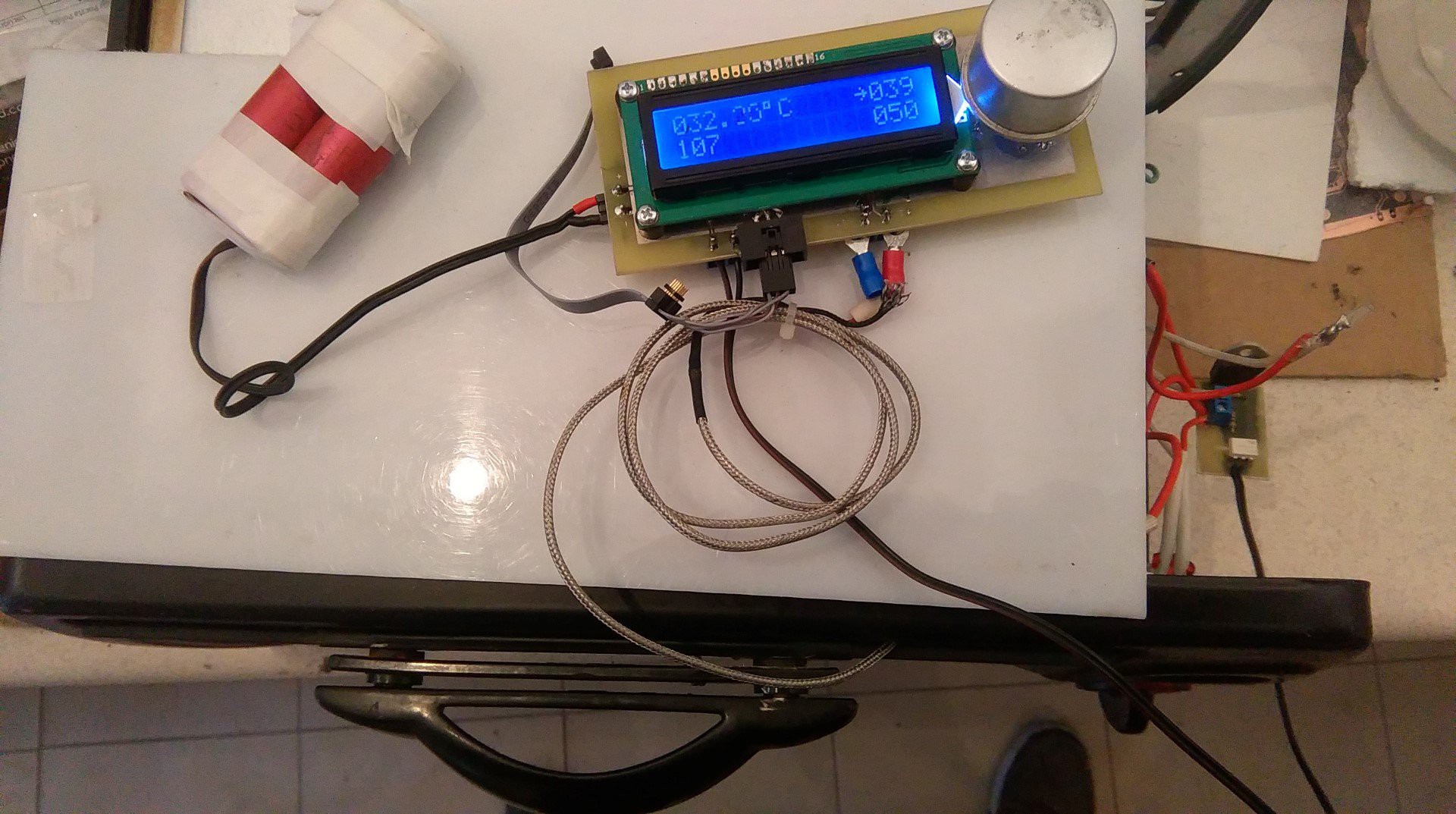

This weekend i connected the board with microprocessor to the board with triac and the oven. I temporary power the board from 7.4V li-ion battery. I inserted the thermocouple inside the oven, on the center of the plate. The task for controller was to keep temperature about 30 deg. Celsius. Actually i use simple on/off algorithm. The temperature in the my workshop was about 18 deg. C. The controller turned on the heater, waited for temperature to reach up to 31 deg. C, and turned off the oven.

The electronic part worked well, the triac didn't heat up itself when he drive 4A of current (900W oven at 230V).

But the temperature inside reach up 70 deg. C, even though the heater was turned off. That is no good, but i think that effect may be decreased if the oven will be work at higher temperatures - i must do some test with 150, 200 and 250 deg. Now i don't want to mount thermocouple near heater, because i want real temperature of the soldered board.

Aleksander Kawęczyński

Aleksander Kawęczyński

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.