I am keeping this super simple!

Any amount of Youtube videos show how to do a 'normal' repair such as :

.

OK....what to do if the 'seat' is stuck? Well since it's brass it strips the square slot for the 'seat tool' fairly easily. If/When that happens break out your dremel multitool and the grinding stone that is 0.65" diameter.

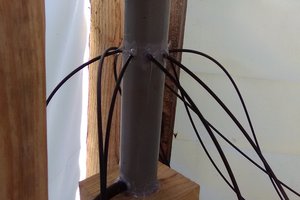

As u can see from the pic it is a bit bigger than the 'seat' (nickel plated brass item).

Step 1: Secure the stone to the dremel and insert it inside of the mixer BEFORE starting it, to avoid bumping the threaded brass on the way in.

Step2: Set the speed midway and hold the dremel as perpendicular as u can to the wall...start grinding gently. If it starts to jitter/vibrate back off and reapply slowly. After 10 seconds, shut down and take it out to inspect the seat...you will see clearly where the rough spots are as they won't be ground shiny.

Step3) Re insert and power up the dremel again...continue a short grind and inspect cycle. After about 2 to 5 cycles depending on how pitted your seat is you'll have a smooth, polished , shiny circle of brass as the reconditioned seat. This only takes 5 minutes to do. Now you are done and you have saved yourself an expensive , wall busting, tile busting, new mixer replacement job! I used a Deoxit Shield spray on all the metal parts to prevent them seizing up again during reassembly.

Anyway, i also showed a copper washer in the pic. I didn't use it. It was PLAN B....if I screwed up the polishing of the seat, plan B was to silicone the copper washer onto the damaged seat and reassemble the whole faucet, keeping it closed overnight to 'set' the silicone. Thus the copper washer would become the new 'seat' for the rubber washer in the stem.

EDIT: After about 18 months I did have to go and place a brass washer on the hot water seat. as shown in the pics.

Okay, after another 18 months or so the hot side started to leak. How did I detect the hot side. Well, run hot water and lock off both hot & cold ..If the leaking water is hot then you know.

This time it was just the rubber gasket that needed replacing. A matter of a couple minutes. I had a 1/2" brass tap 'washer type' flat gasket on hand that I used. Had to trim it's diameter with a good scissors as it was too large. Just make it small enough to insert freely into the mixer's shaft and all is good.

Be sure to apply a bit of light oil, like sewing machine oil to lubricate all the threading and the on/off twist action b4 u reassemble.

mosaicmerc

mosaicmerc

Moritz Wenzel

Moritz Wenzel

Jan

Jan

matthewkleinmann

matthewkleinmann

"This video is unavailable"...