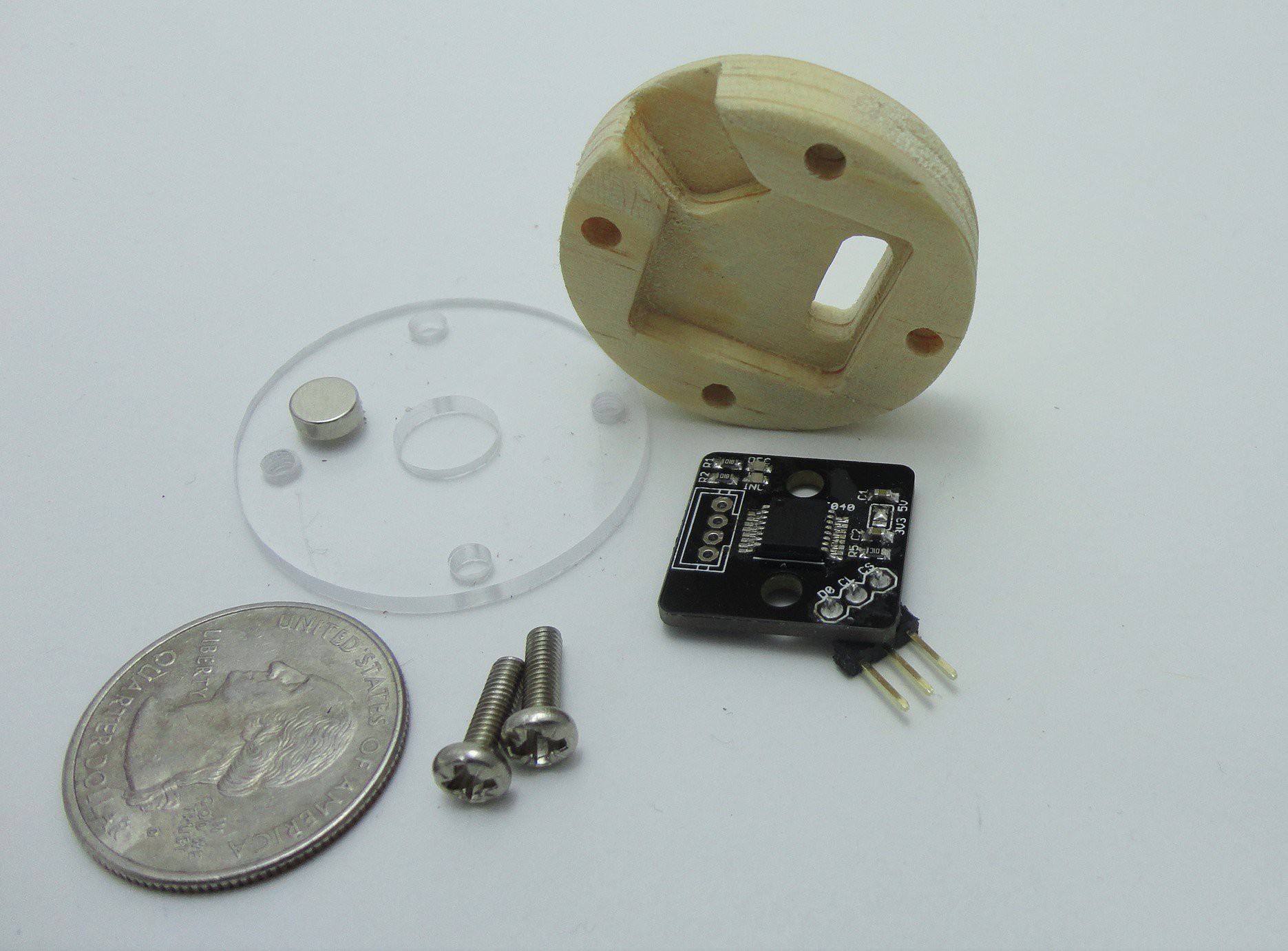

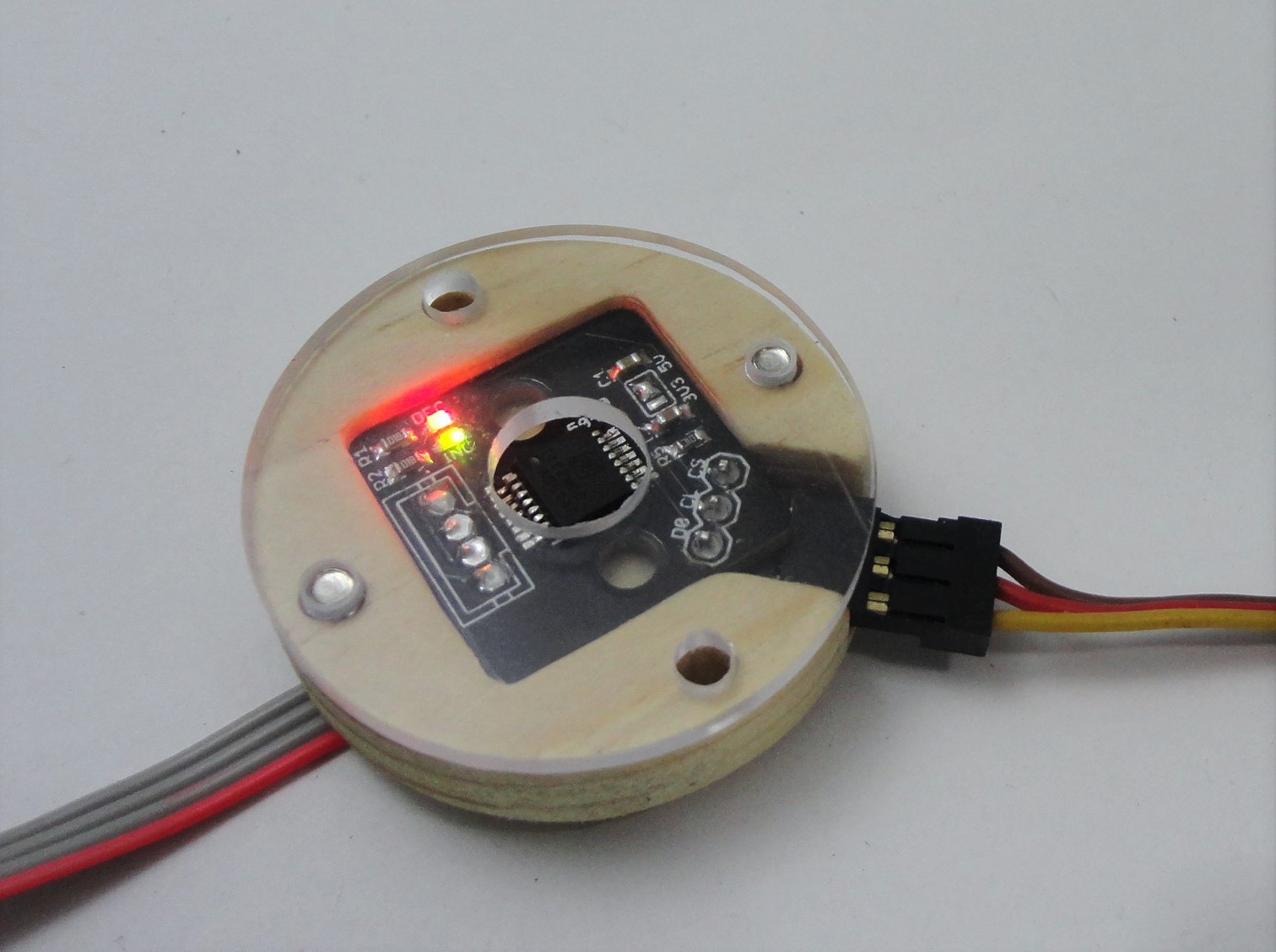

The PCB can be mounted using the two holes next to the IC, but I also wanted to have an enclosure for the module for scenarios that demand more protection. I designed and milled a case for the PCB (relevant design files in the repo). I made the base from pine (my plan was to use acetal or polyethylene, but I didn't have any of those materials stocked). The cover is made from clear acrylic, with two of the four bolt holes drilled to accept threading with a 3 mm tap.

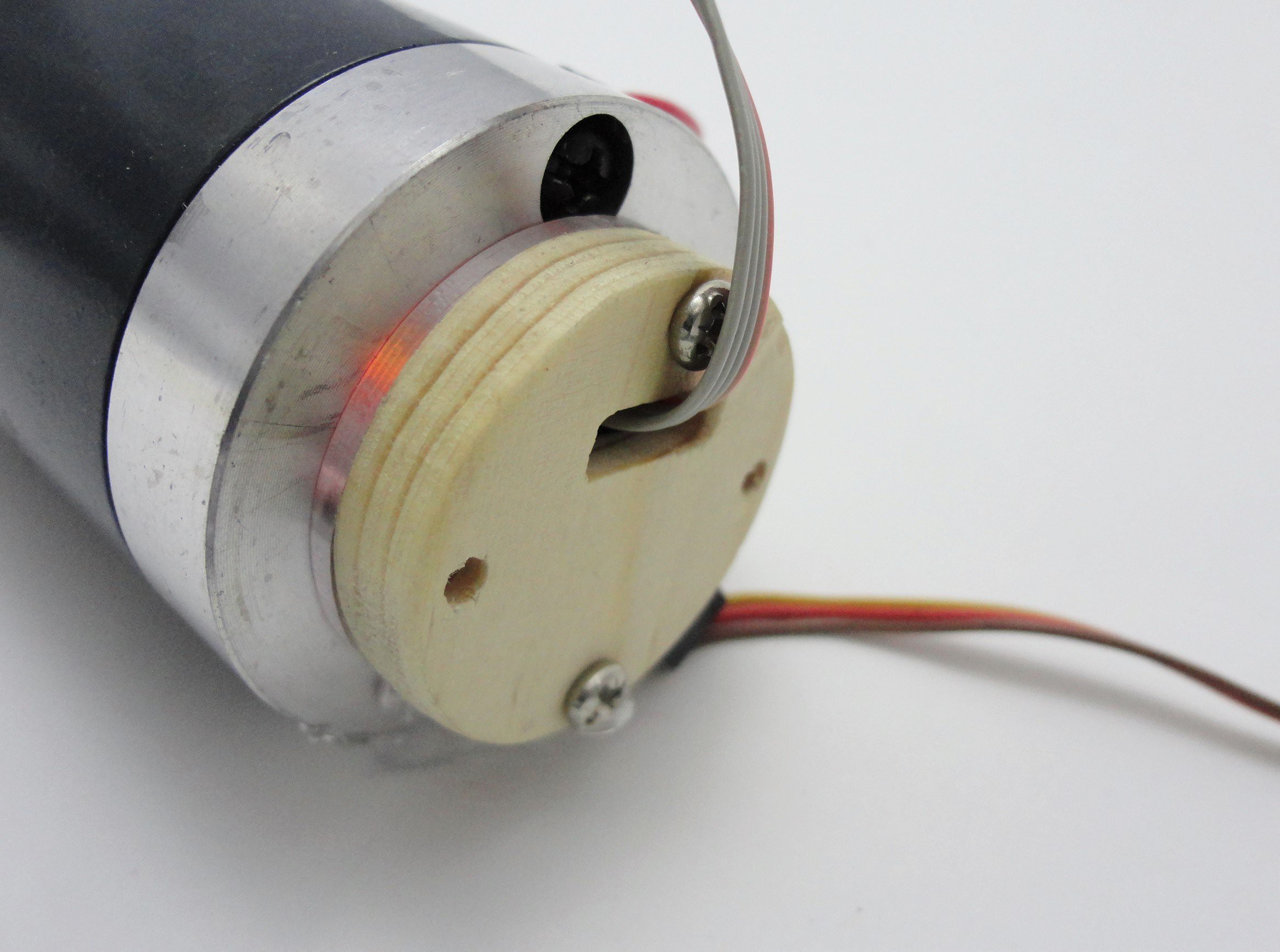

Mounting the case onto something like a motor prevents the user from being able to see the alignment LEDs directly. This is where the acrylic cover comes into play, because it allows the light to be seen on the edge of the part.

ottoragam

ottoragam

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Diggin' the LED/acryllic aspect!

Are you sure? yes | no

Glad you like it! Btw, your commonCode certainly looks useful.

Are you sure? yes | no