A bandanna has become an essential element of my "daily carry". A true multi-purpose tool, a bandanna can be used as headwear, face protection, cleaning cloth, bandage, work surface - literally a thousand other uses. And you can blow your nose on it. Naturally, I want to make my own.

Classic bandanna-style handkerchiefs were often created using a "lost wax" printing process, known as Batik, to print intricate patterns on squares of cloth. Wax is applied to the fabric, often with skillfully- carved wooden stamps, and the fabric is subsequently dyed a bright color. For multi-color designs, this can be repeated several times, using different colors for each dyeing.

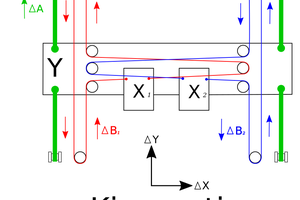

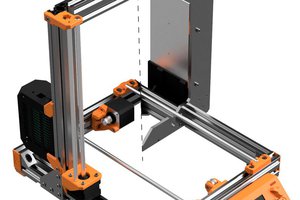

Working (OK, playing) with 3D printing and CNC projects have given me the knowledge and skills to design a hybrid CNC Batik printer. Marlin software can easily be adapted to this, as could GRBL. Precision framing and linear motion parts are cheaply and readily available. I prefer to use ubiquitous components like MakerSlide, in readily-available dimensions, but am open to adapting existing parts to this project if appropriate and workable.

Novel and necessary development will include:

optimization of large CNC gantry and linear motion

limited Z axis travel, possibly utilizing a solenoid to reduce cost and complexity

a fabric frame that fits into the PaisleyBot

a registration system for sequentially printing adjacent patterns on a larger piece of cloth

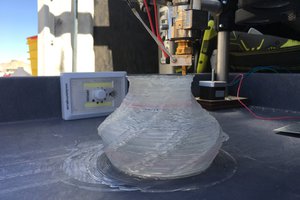

testing and custom firmware adjustments for working with liquid wax on different cloths

possible switchable printing head to print with ink on previously batik-dyed fabric (a classic bandanna technique)

receptive to suggestions and requests

All documentation and design work will be posted to Git. Not that I know anything about Git, but I am a quick study. Any and all 3D printed parts will be readily available from my Thingiverse repository as well, with a pointer to Git.

theschlem

theschlem

Atte Linna

Atte Linna

Sam Smith

Sam Smith

gregsaun

gregsaun