I needed a tap... didn't have the right size/threading...

Inspired by the self-tapping bolts I found earlier, I tried to make one, myself... and it works, amazingly well, with aluminium, anyhow.

(I tried a *much* smaller one, which worked great for about half the depth and, of course, broke off).

I think this one's 10-32

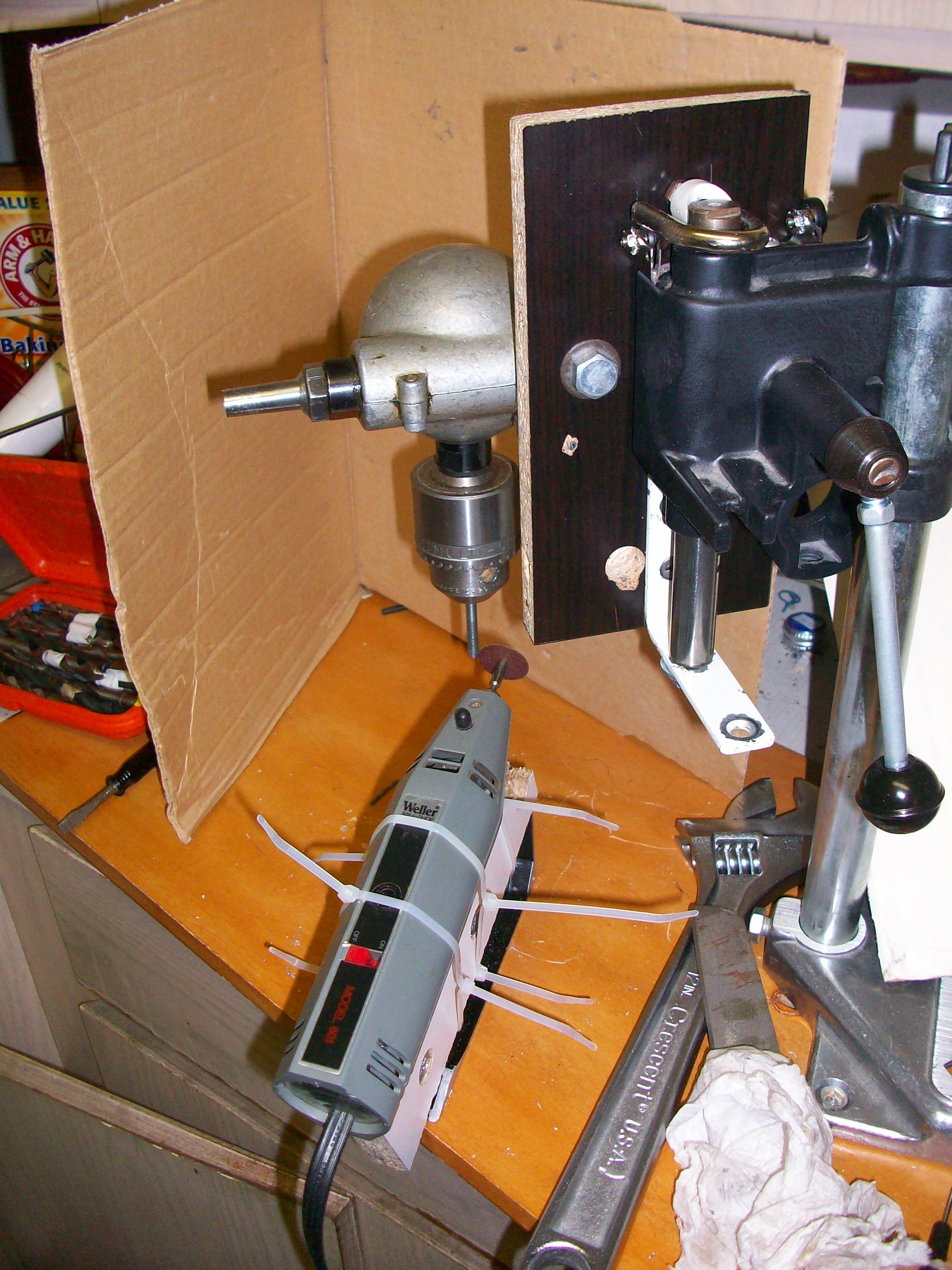

Here's the setup:

The idea was to cut the flutes at an angle such that the lowest on the "tap" would cut first.. I don't know why, but this made sense to me. So I set up this jig aligned at a slight upwards angle (hard to see in the image). Also, attempted to align the cut so it would be sharper than 90-degrees. The dremmel is rotated into the bolt. The first cut was darn-near perfect as far as the <90-degree cutting-edge, but the next two came at different angles. Also, I think I got it backwards as far as lowest-cutting-edge-first. Despite that, it's worked great for many taps.

With it chucked in the "drill press" I spun it for a bit to file a slight angle... The intent was to get the tip down to the "bottoms" of the threads, but not much deeper.

It's hard to see, here, but somewhat apparent that my dremmel-jig didn't assure <90-degree cuts...

And here's a tap that it did... This is a cutting of an old hard-disk case to be used as a right-angle bracket (another can be seen under the dremmel-jig)

I tapped *8* of these dang holes with that single 10-32 bolt, in the thickest parts I could find on my "angle brackets"... I also tapped two plates to be used to move a linear-carriage along threaded-rod.

I bloodied up my knuckles several times as the flat-head screwdriver slipped out of the screw-head, before I realized the ultimate solution was to slice two sides off the circular screw-head and use that in a crescent-wrench. Guess I didn't take a picture of that... but...

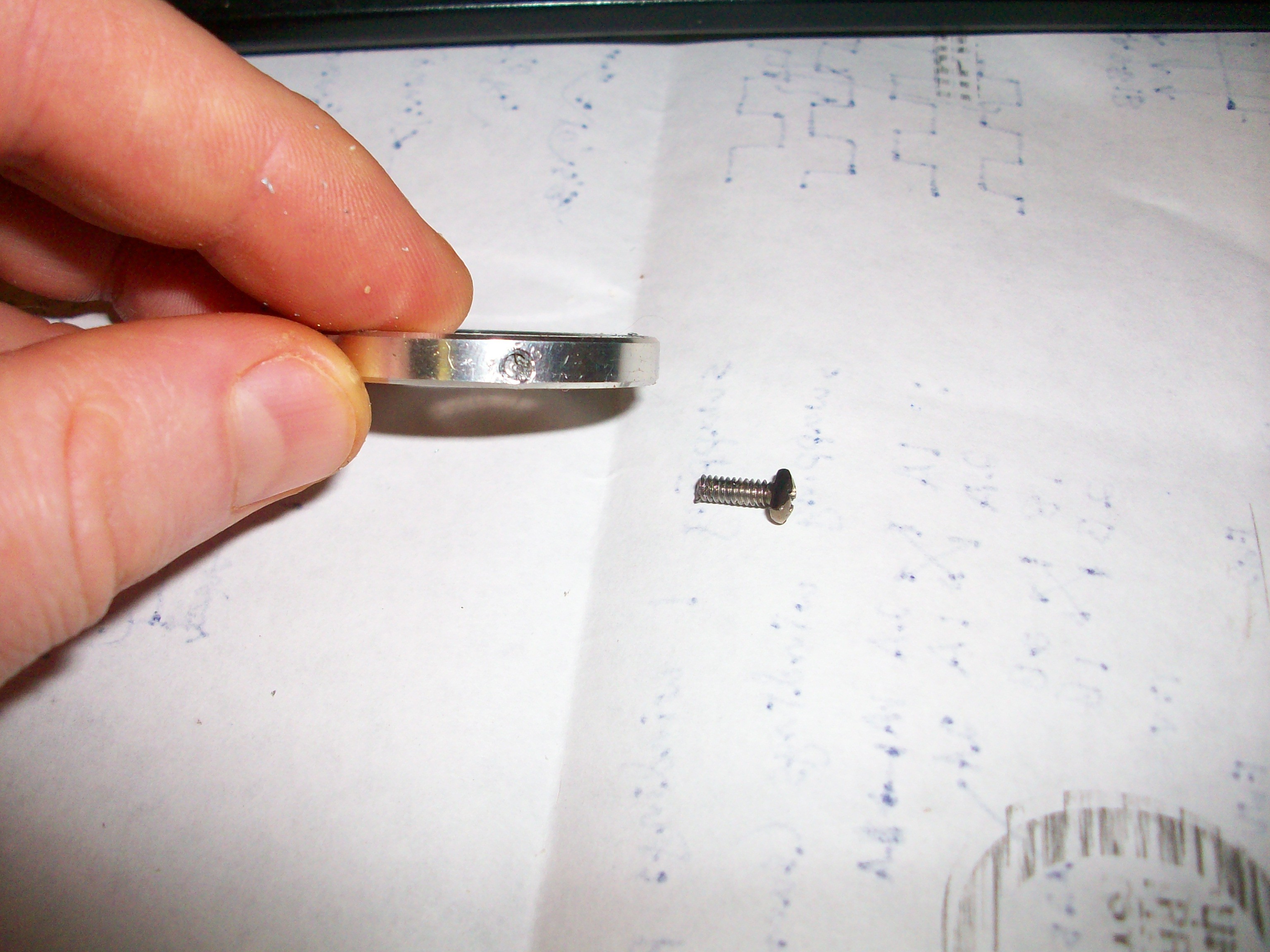

Here's the "Much Smaller" one... I don't know its size, maybe 4-40?

You can see the sliced-off sides, for using in a crescent-wrench, and the aluminum(?) ring (from a hard-disk) in which it broke...

Here's the linear-system, and my "machine-shop." You can see the angle-brackets installed in the system.

Eric Hertz

Eric Hertz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.