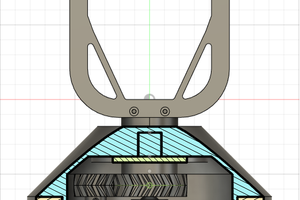

This project started much earlier this year, maybe in April, May... Maybe even last year, I honestly can't remember. It started out as a sort of modularisation project - I wanted to upgrade the size of the wheel rim on my G27 (mainly so I could add a quick release mechanism), but that meant I'd need to upgrade the motors to retain the stock torque, but that meant I'd have to do away with the gear drive mechanism because it's far too loud even with the weedy stock motors and of course I'd need to upgrade the similarly weedy MOSFETs (I mean, they fit two in one heatsinkless SOIC package in a case with no active cooling!). So I set about investigating the wheel to figure out how to convert it to belt drive. I got as far as buying all the mechanical components but then I moved in with my girlfriend almost immediately afterwards and I haven't had enough spare cash to spend on laser cutting the enclosure for it. In fact I haven't even moved my G27 back in yet!

Anyway, so now the idea is that since I've already done some research, possibly more than I've found anywhere on the internet after many hours of searching, I might as well compile it into a sort of master document of everything anyone might want to know about the wheel.

neema_tas

neema_tas

Mike Maluk

Mike Maluk

Adam Curtis

Adam Curtis

caver.adam

caver.adam

Swaleh Owais

Swaleh Owais