As I already stated in another of my projects, Dextra, I consider the human hand the most versatile tool we use in our daily lives. We use our hands for almost every action we perform in a normal day. The problem I addressed with Dextra is what happens when you do not have one or both hands, and how can this problem be alleviated. But, what if you have both hands but you cannot move them? The problem still remains, you have to face your daily life with a serious limitation. And this situation is more common than it seems: cerebral vascular accident, or stroke, remains the leading cause of adult disability and it is estimated that there are nearly 800,000 stroke incidents in the United States annually. Nearly 80% of stroke survivors suffer hemiparesis of the upper arm and impaired hand function is reported as the most disabling motor deficit [1].

For the above reason, there is a need for some kind of device that serves as a means to either rehabilitate a person suffering from the disabling condition until he or she regains hand functionality, or if this is impossible to achieve, as a means to assist hand motion so that the person can carry out his or hers daily activities as normally as possible. To this end, exoskeletons, a subclass of wearable robotic devices, are being developed to help people mobilize their affected limbs.

However, conventional exoskeletons are often bulky and heavy, and suffer from a problem known as joint misalignment. This problem arises because the kinematic chain of the wearable robot overlaps that of the human body, and, as the latter is very complex and difficult to replicate, usually the differences between the two cause interaction forces, joint misalignment and motion restrictions, which ultimately cause discomfort and difficulties in controlling the device.

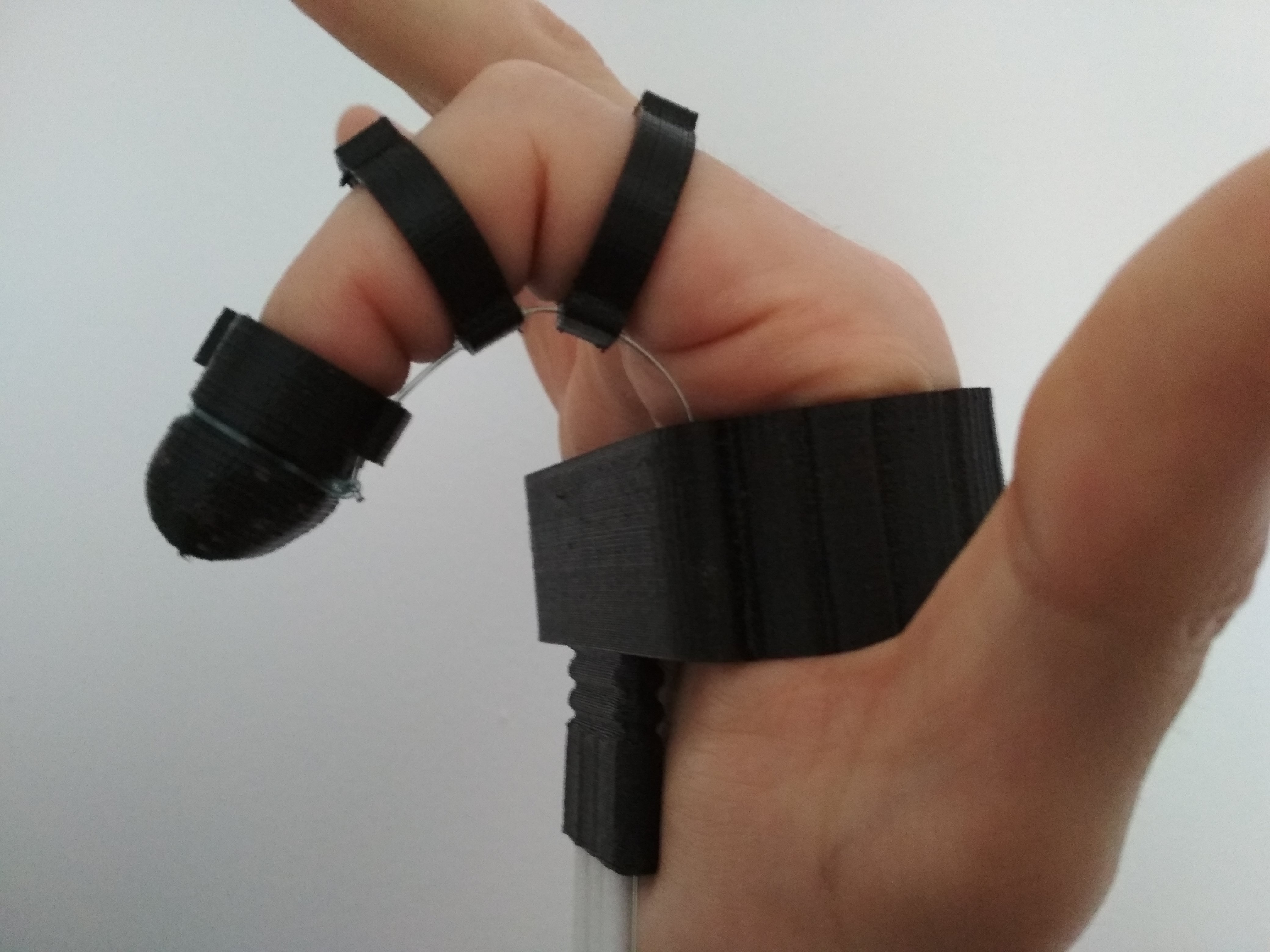

Soft exoskeletons, a new type of exoskeletons that have emerged in recent years from the conjunction of soft robotics and wearable robotics, get rid of most of the problems that conventional exoskeletons have. In a soft exoskeleton, the rigid frame of a conventional exoskeleton is replaced by textiles that transmit the forces generated by the actuators to the user’s limbs and provide support for the actuators, electronics and power sources. By getting rid of the rigid frame, a soft exoskeleton is usually lighter and also avoids problems related with joint misalignment that conventional exoskeletons usually have, providing a minimal impediment to the wearer’s motions. The downside of this approach is that, in the absence of a rigid structure, the user’s skeleton must withstand the external loads as well as the forces generated by the actuators. For this reason, soft exoskeletons are usually designed as rehabilitation/assistive devices and not as force augmentation devices.

Graspex is designed following this soft exoskeleton paradigm. The idea is to build a hand rehabilitation/assistive soft exoskeleton that will be completely open-source, so that it can be easily replicated and modified. To this end, all mechanical parts will be designed to be 3D printable, but because of the soft nature of the device, most of them will be made of flexible TPU filament. The actuation system will be based on compact DC motors connected to the fingers by means of artificial tendons. To prevent the wrist position from affecting force transmission, the output of the actuators will be connected to the palm of the hand through a Bowden transmission system. Control electronics will be based on an Arduino-like microcontroller (or a Raspberry Pi Zero if complexity increases), to widen the range of people that will be able to hack the device. Having a fully hackable hand exoskeleton will allow anyone to use the device not only as originally intended, but in many other ways, for example as a force feedback device for virtual reality.

Main features

- Structure made of fabric (a glove) and flexible materials (TPU filament).

- Compact actuation system located on the wrist or forearm (based on the Dextra actuation module).

- Force and motion transmission system based on artificial tendons and Bowden cables.

- Human-machine interface: pressure sensors on the fingertips and/or EMG signals.

![]()

License

Code is licensed under the GPL v3 License. The rest of the work is licensed under the Creative Commons Attribution-ShareAlike 4.0 International License.

Alvaro Villoslada

Alvaro Villoslada