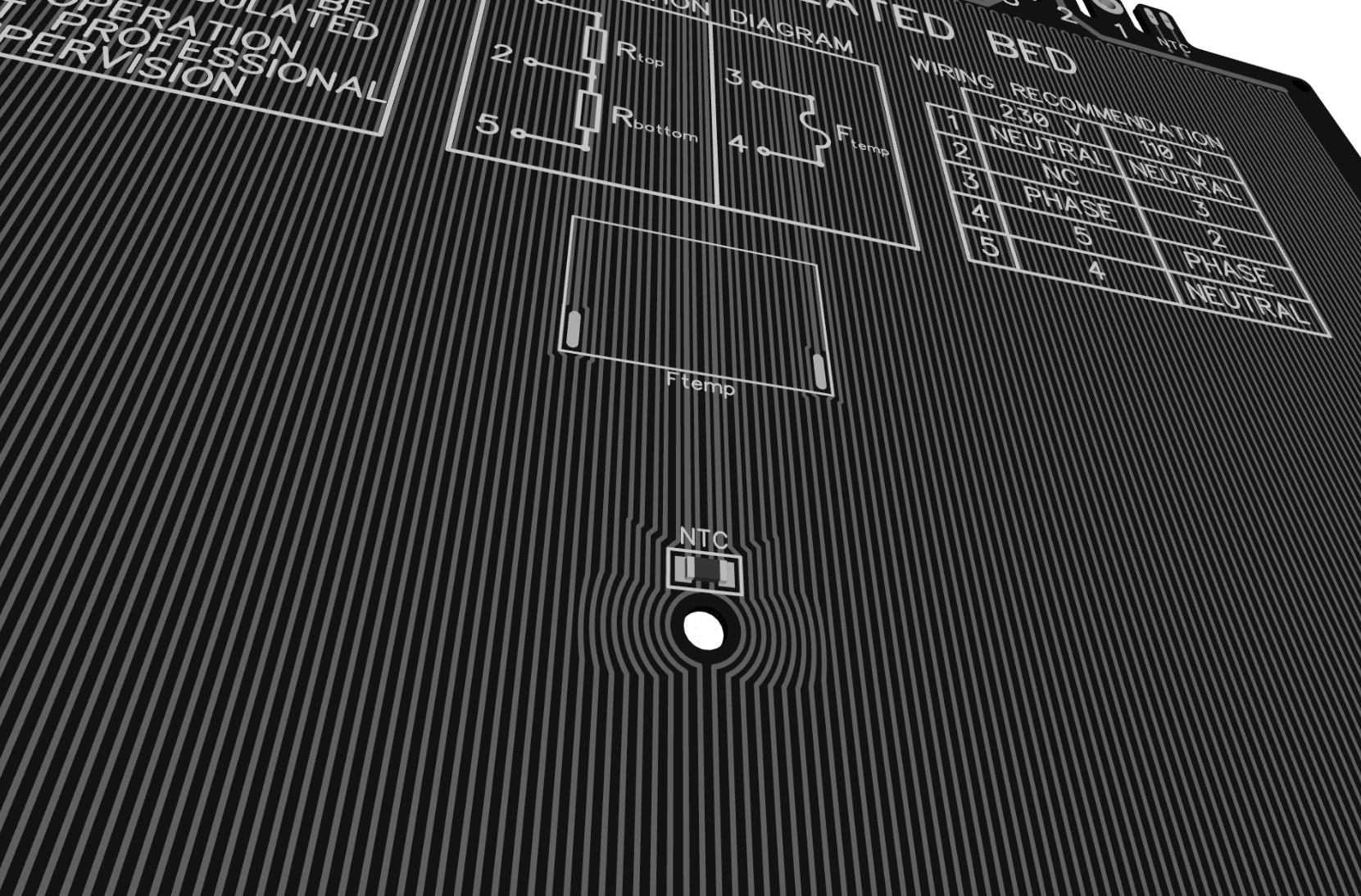

NTC

While fiddling around with the traces to squeeze in the NTC, it became obvious that adding the NTC to the board was not the great idea I thought it was, simply because I need to maintain a proper clearance between the high driving voltage and the low logic voltage to prevent arcing.

A friend helped me through the related norms, such as IPC2221B and EN60664, and it turns out that a minimum insulation distance of 2.3 mm would be required. Since most RepRap electronics are not sealed from touch, we have to consider a good safety margin on top of that, about 100%, ending up at 4.6 mm clearance. Of course, this large distance would also functionally affect the sensor, which should be really close to the heating traces in order to get responsive and accurate readings.

So, if you can't do it right, don't. Because of this and until I get a better idea, I will drop the NTC from the design. The NTC can be mounted and insulated in many better ways, making use of kapton or mica, so there's no also need to compromise uniform heat distibution here.

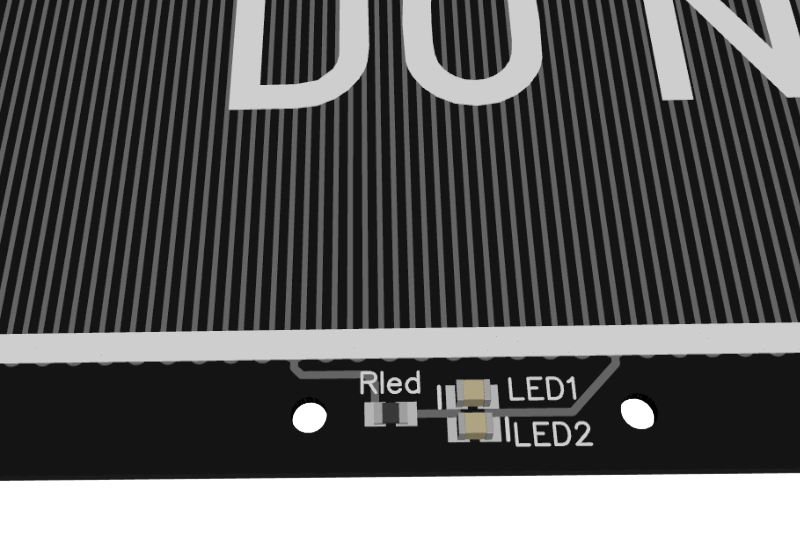

LED circuit

As said, I dropped the LED overcurrent fuse, so the double sided cover will not be required any more.

![]() New silkscreen

New silkscreen

Alright, I know, this project log is not all that exciting :) But look at the new cool silkscreen. It has a lightening bolt on it to remind the user of the fragility of life.

Moritz Walter

Moritz Walter New silkscreen

New silkscreen

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Yes, the new silk screen looks good with the high voltage warning. I agree with dropping the NTC from the design.

Are you sure? yes | no