In the previous logs I have barely mentioned the interfacing with the HP45, although it is quite an important part of this project. The best I did was this log, where I spent 62 words on the problem. In this log I will give some more background on what the problem with the HP45 is and how to work with it.

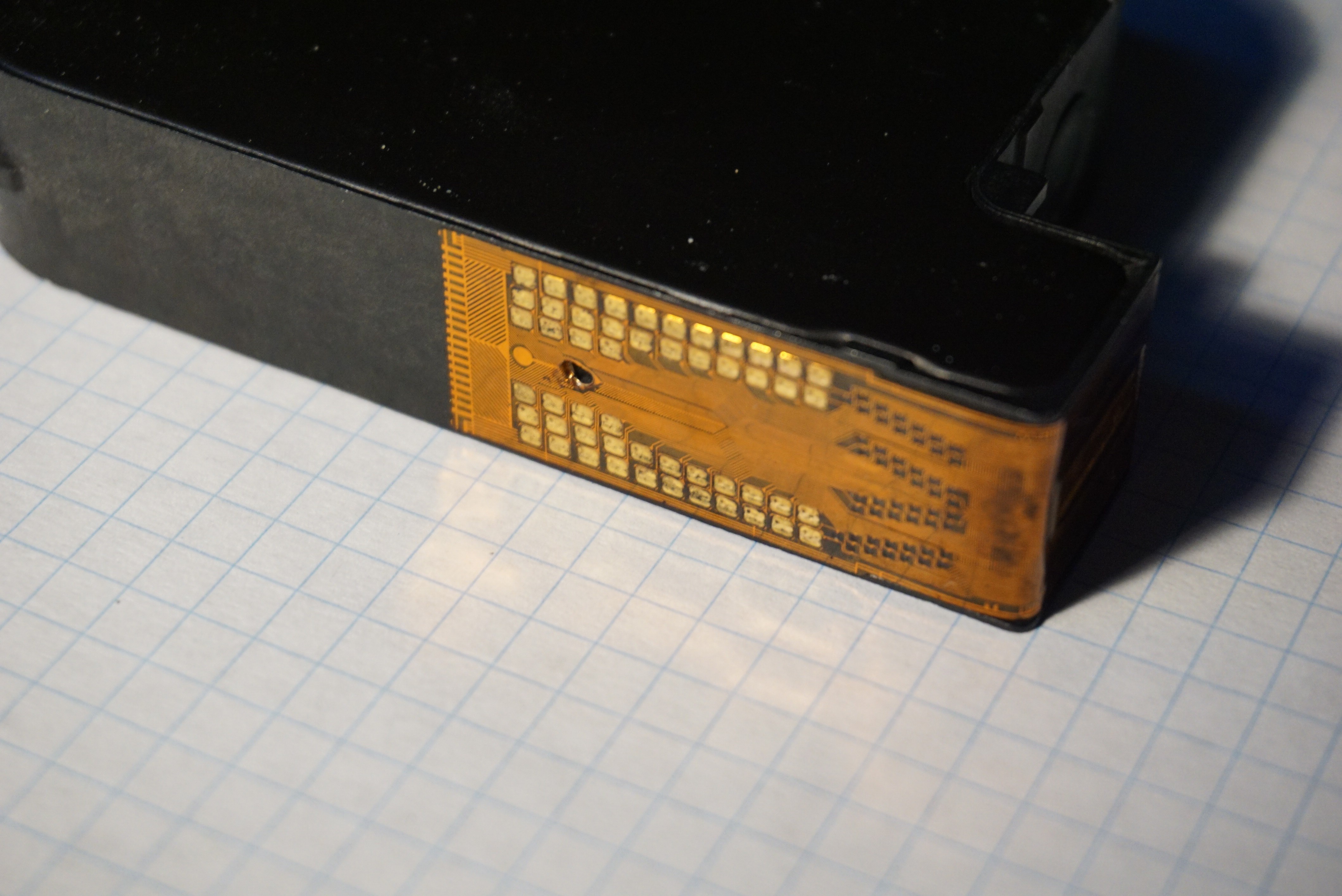

When you look at it the problem is quite simple. The HP45 has too many pads. Reliably connecting to 2 or 3 pads is simple. Reliably connecting to 52 is a bit more difficult. Depending on what pad you lose, you can lose between 14 and 22 nozzles. The problem with this many pads is so big most manufacturers don't bother with it anymore. They just put some more electronics in the printhead itself. The HP45 is between the first inkjet printheads where they were figuring it out, and the later printheads where they optimized the design.

Pogo pin connector

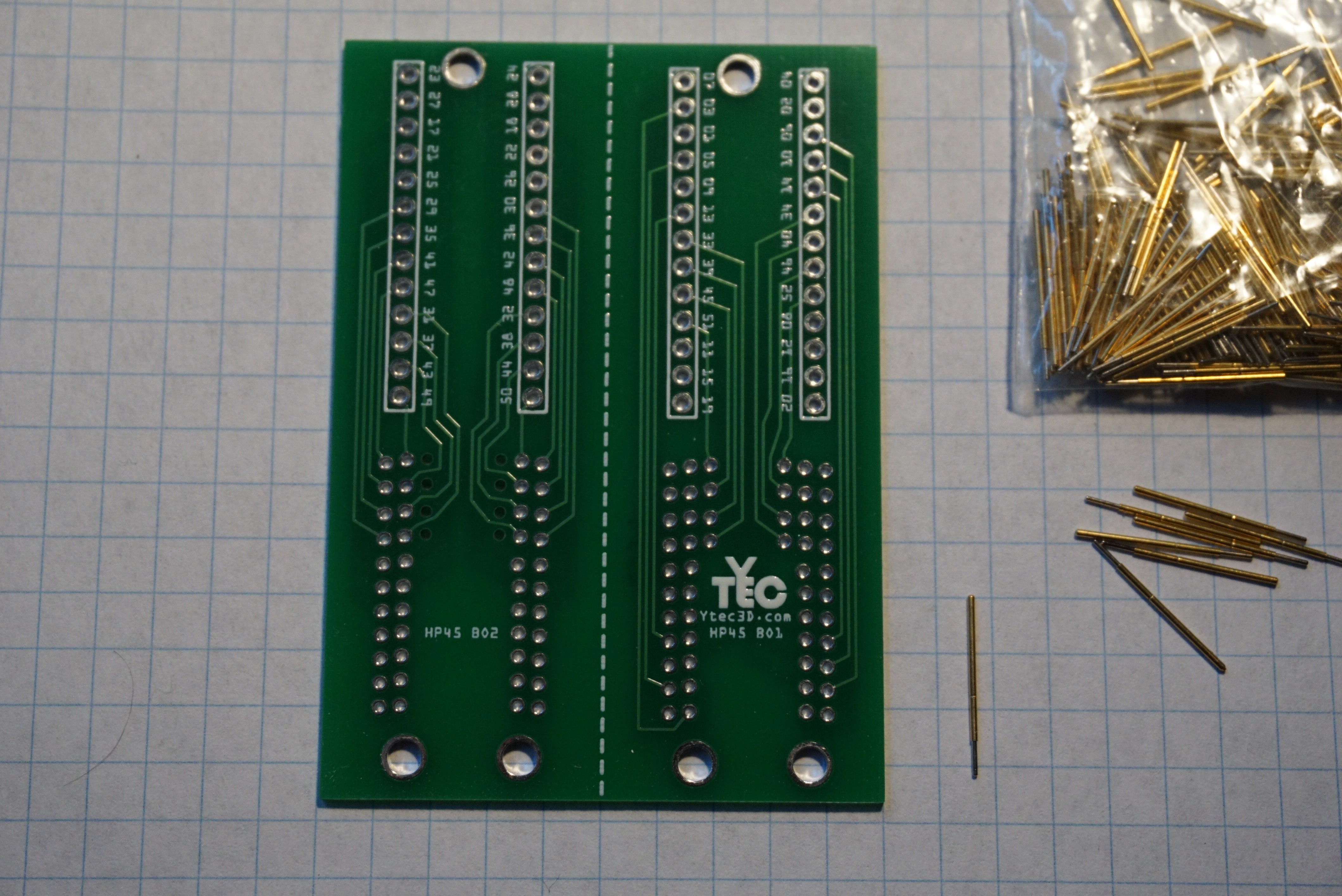

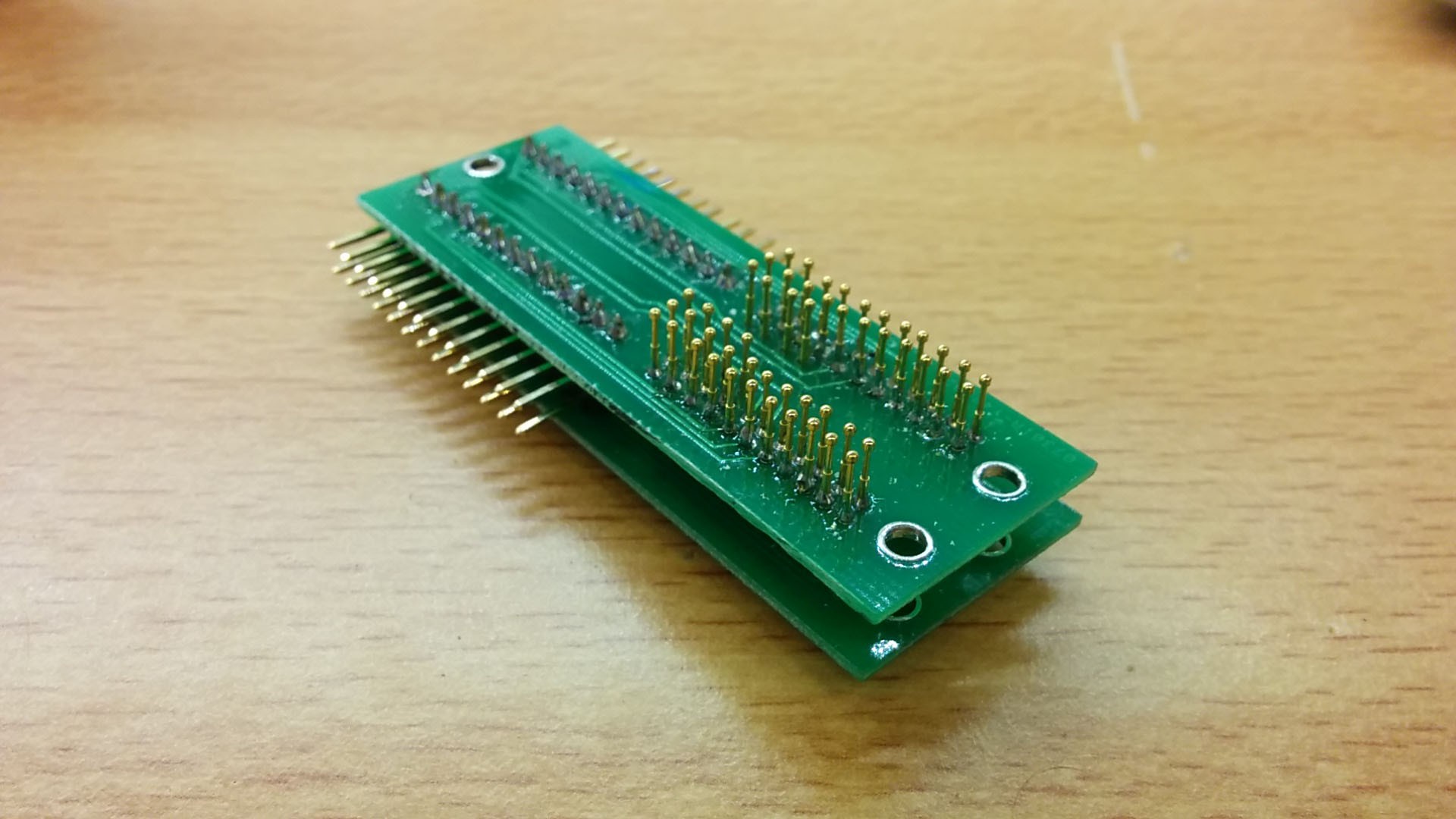

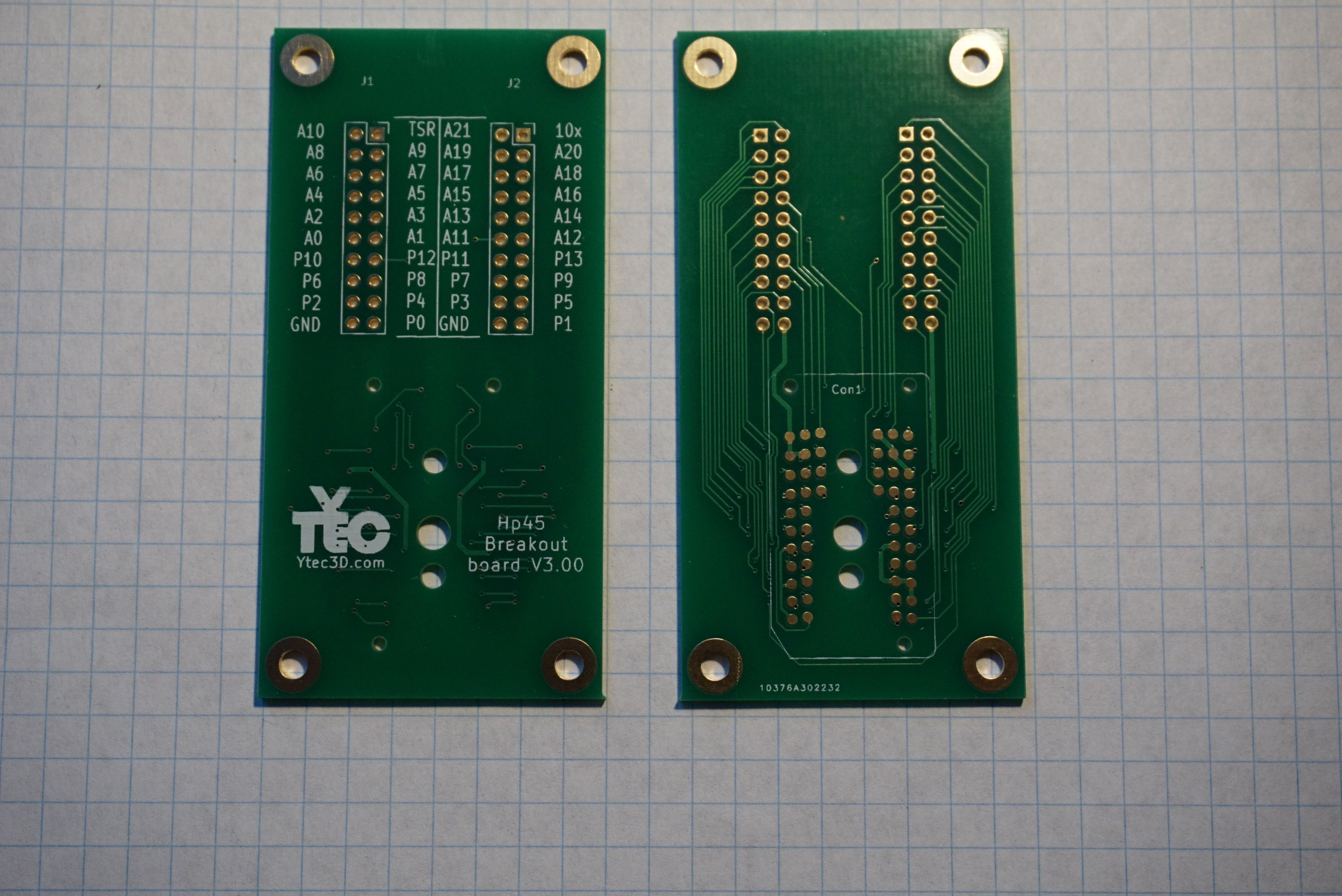

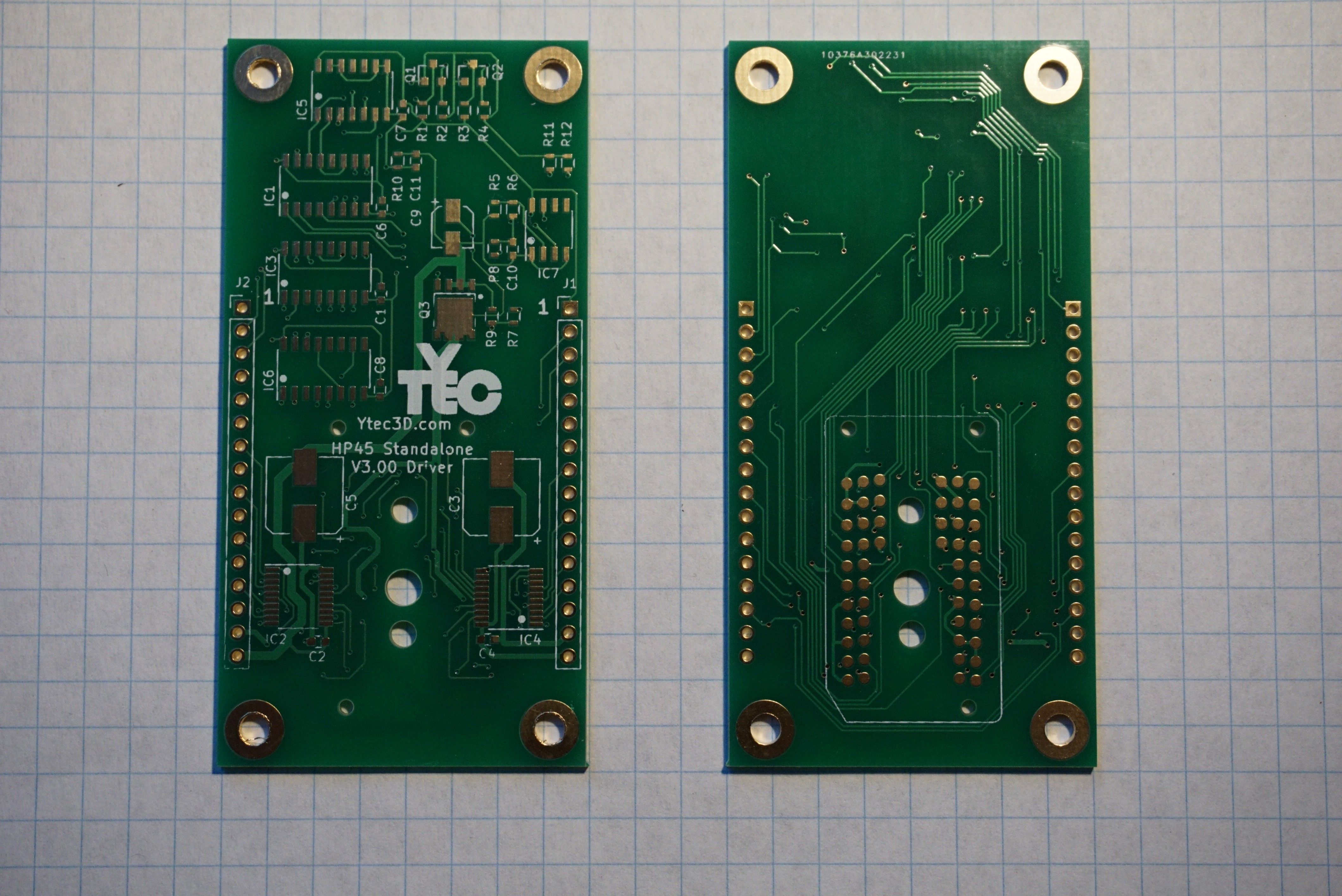

My first way of connecting to the HP45 is with a pogo pin board. I have had breakouts and full drivers built this way. They are built on 2 boards to give the pins stability and to make routing somewhat possible with a 2 layer board. It is practically impossible to route without more than 2 layers, because all pogo pins are essentially through hole, and you cannot reach all the pins at once.

In all fairness, it worked quite well. It is not perfect though. The pogo pins are only 0.8mm thick and so are incredibly fragile. In most printhead carriers you inert the printhead from the top. This means it is easy to hit the pins sideways while loading a printhead. This has happened, and the pins cannot take any sideways load and simply bent. The pins are soldered to both boards, so if a pin gets bent, you have to desolder it from both boards at the same time. I have done this, but it is the absolute worst job to do.

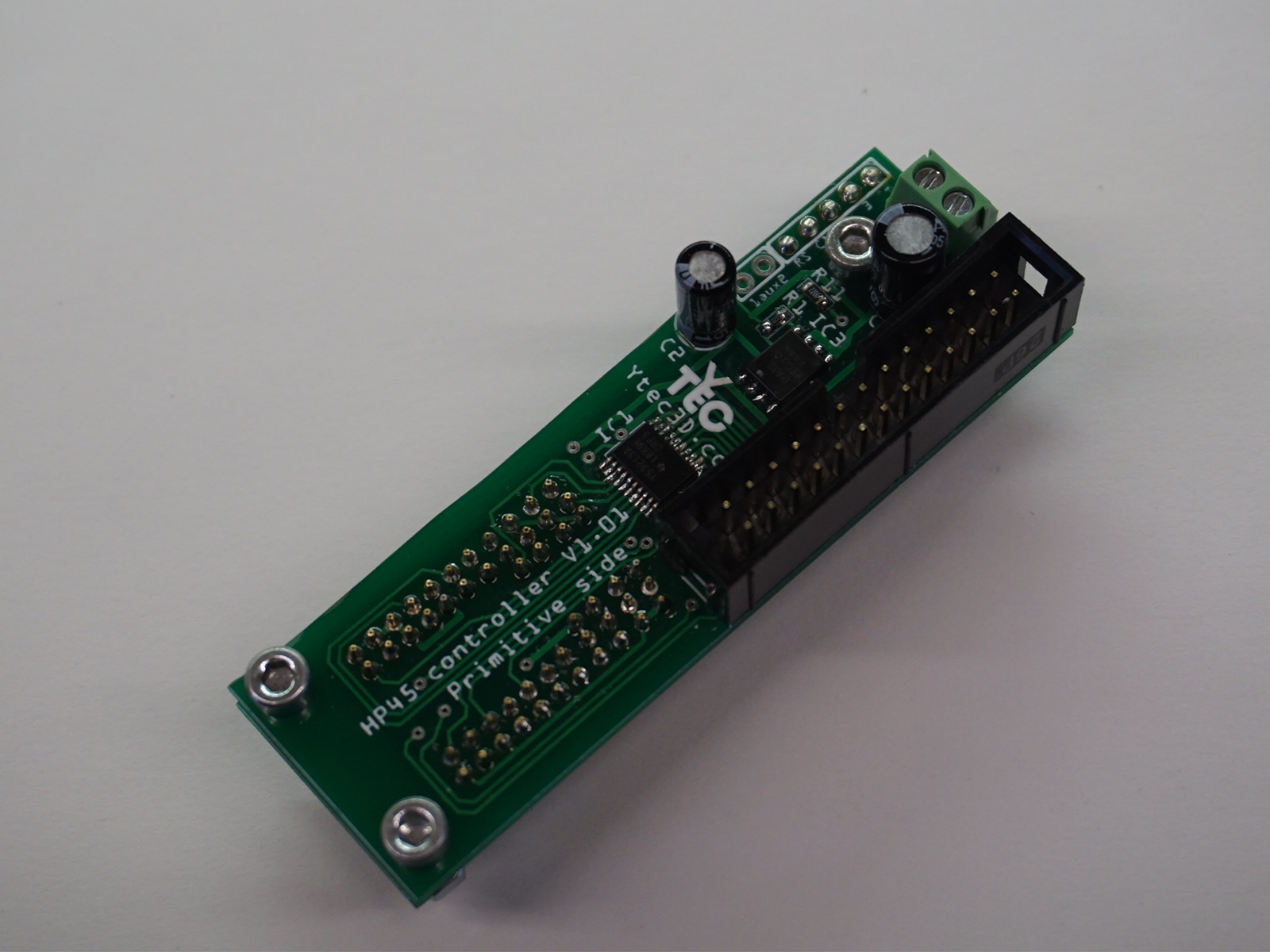

Cue the HP45 connector

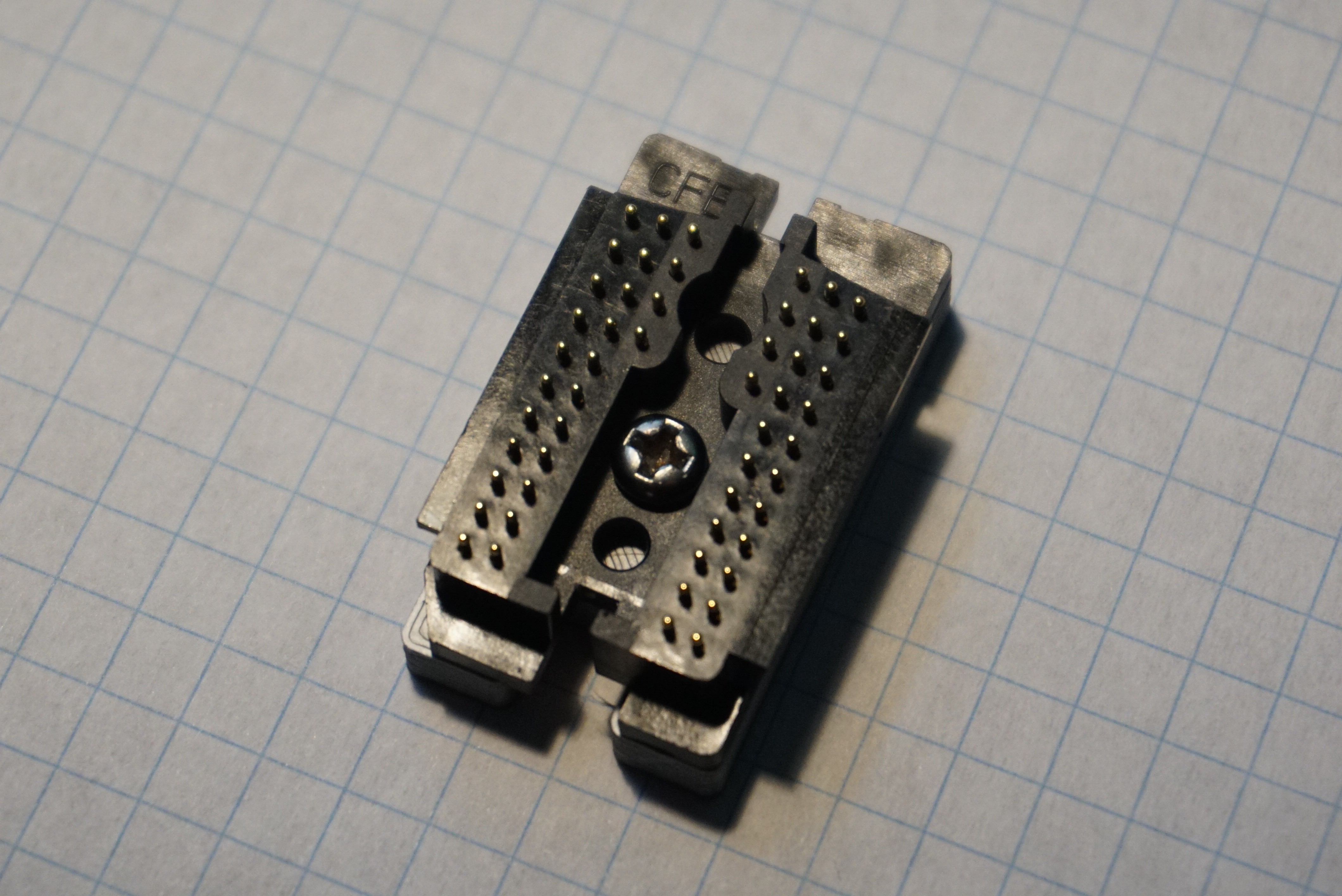

Fabulous, isn't it?

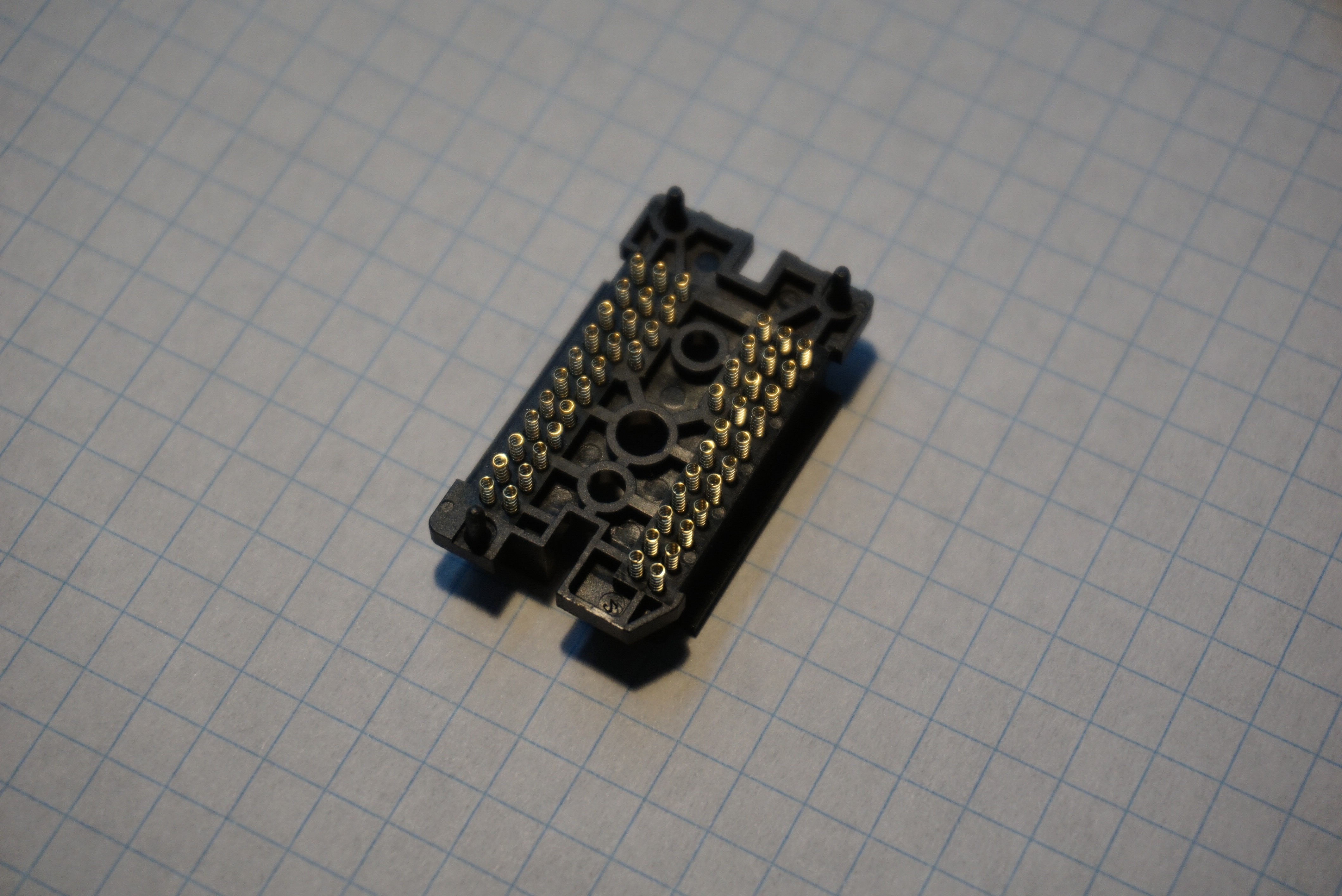

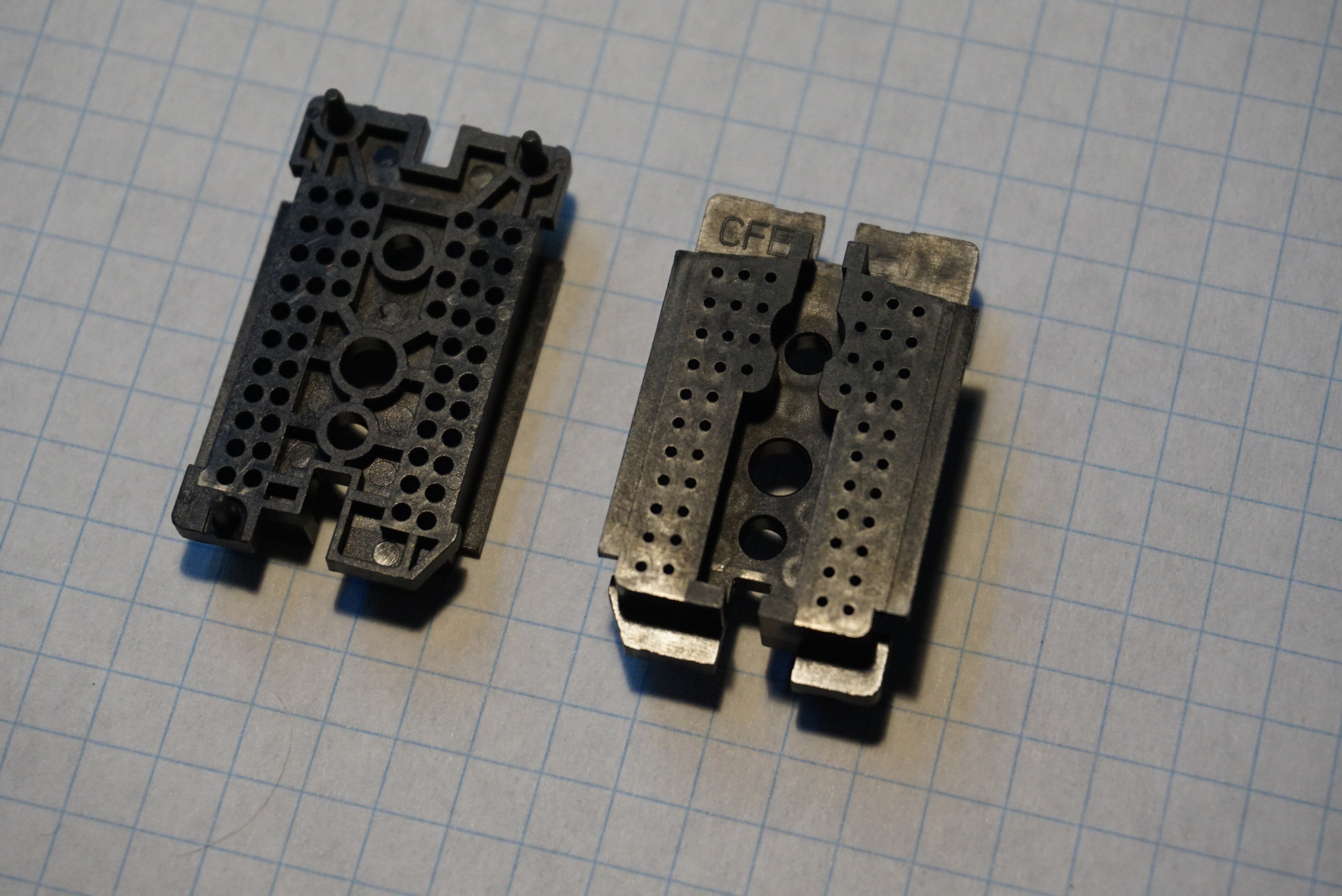

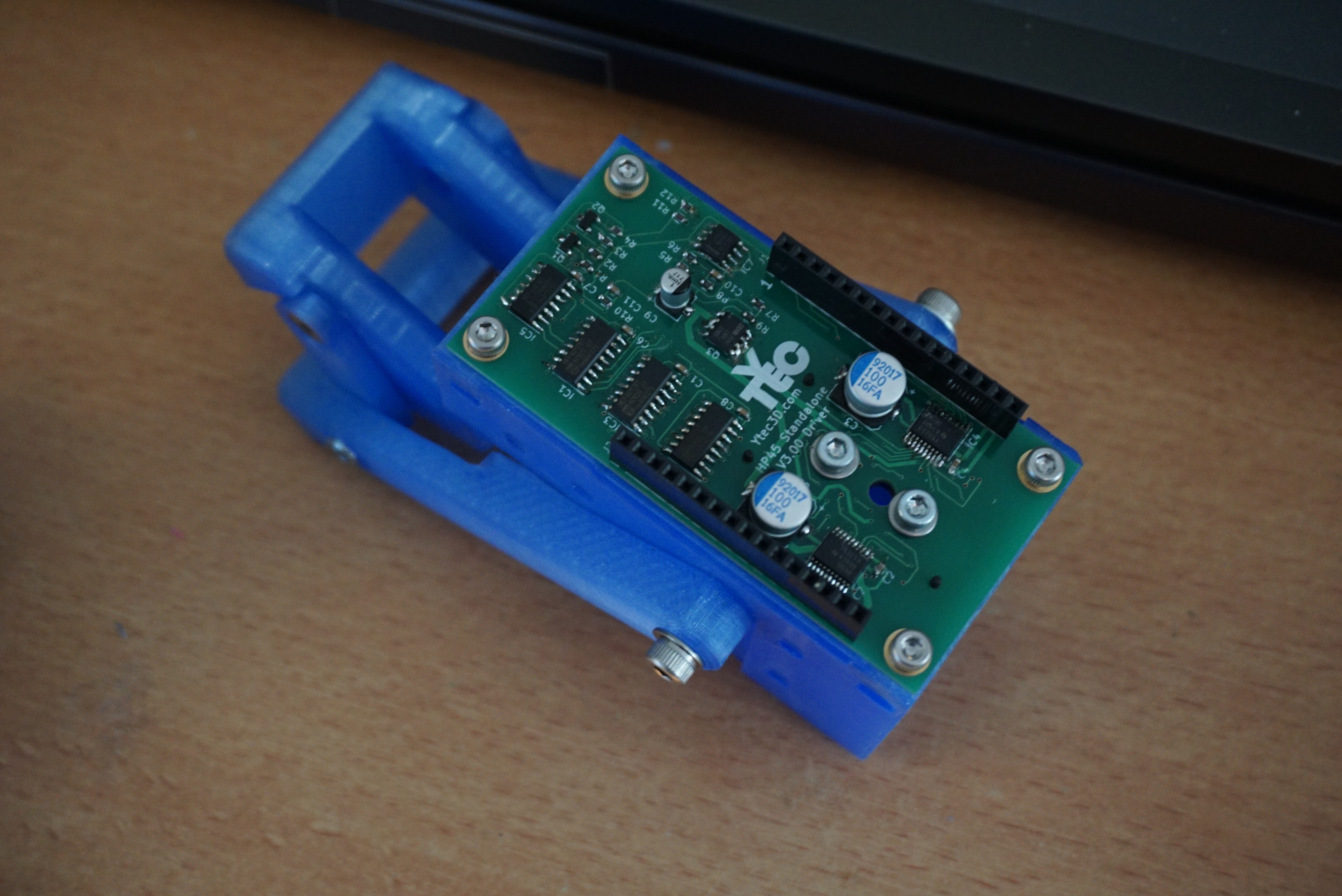

The HP45 connector is a purpose built connector that has 52 pogo pins in a single plastic housing. It does not have the travel of my own pogo pin circuit (not that you need it), but it has pins that you can hit sideways without breaking them. Also it does not solder in place, but makes contact with the PCB pads, giving more freedom in routing. In my case I can now route on a single 2 sided PCB.

The HP45 connector is founds here: https://www.cfconn.com/product-show_14712/. It is also on Alibaba through the same supplier. While it states it can supply small quantities for under $10, my experience is that those prices start happening at size 100. You get these connectors unassembled, dropping an assembled one is cause for much tears.

I myself have bought a batch at CFConn. I now have way to many. I sell them on Tindie right now. I will start selling more HP45 related components later when the documentation is finished.

https://www.tindie.com/products/Dragonator/hp45-printhead-connector/

The HP45 connector uses tiny gold plated springs and pins in a plastic housing to make connection to the HP45. The travel is about 1.5mm on each pin.

3 locating pins locate the connector to the PCB. 3 holes can be used to mount the connector. the 2 outer holes are 2.8mm, the inner hole is 3.85mm. I use the 2 outer holes with M3 cutting into the holes, but I am still looking for proper plastic screws. To make a connection with this printhead, you'll need 52 located pads on a (preferably gold plated) PCB. I have included the KiCAD files on the page of the connector, here on my own site, or is in the electronics section of the source files.

I currently have 2 boards, a breakout board that breaks the 52 pins out to 2 2x10 pin boxed headers (grounds are shared) and 1 driver board. The driver board also needs a controller to work, which is a separate board stacked on the driver board through 2 headers.

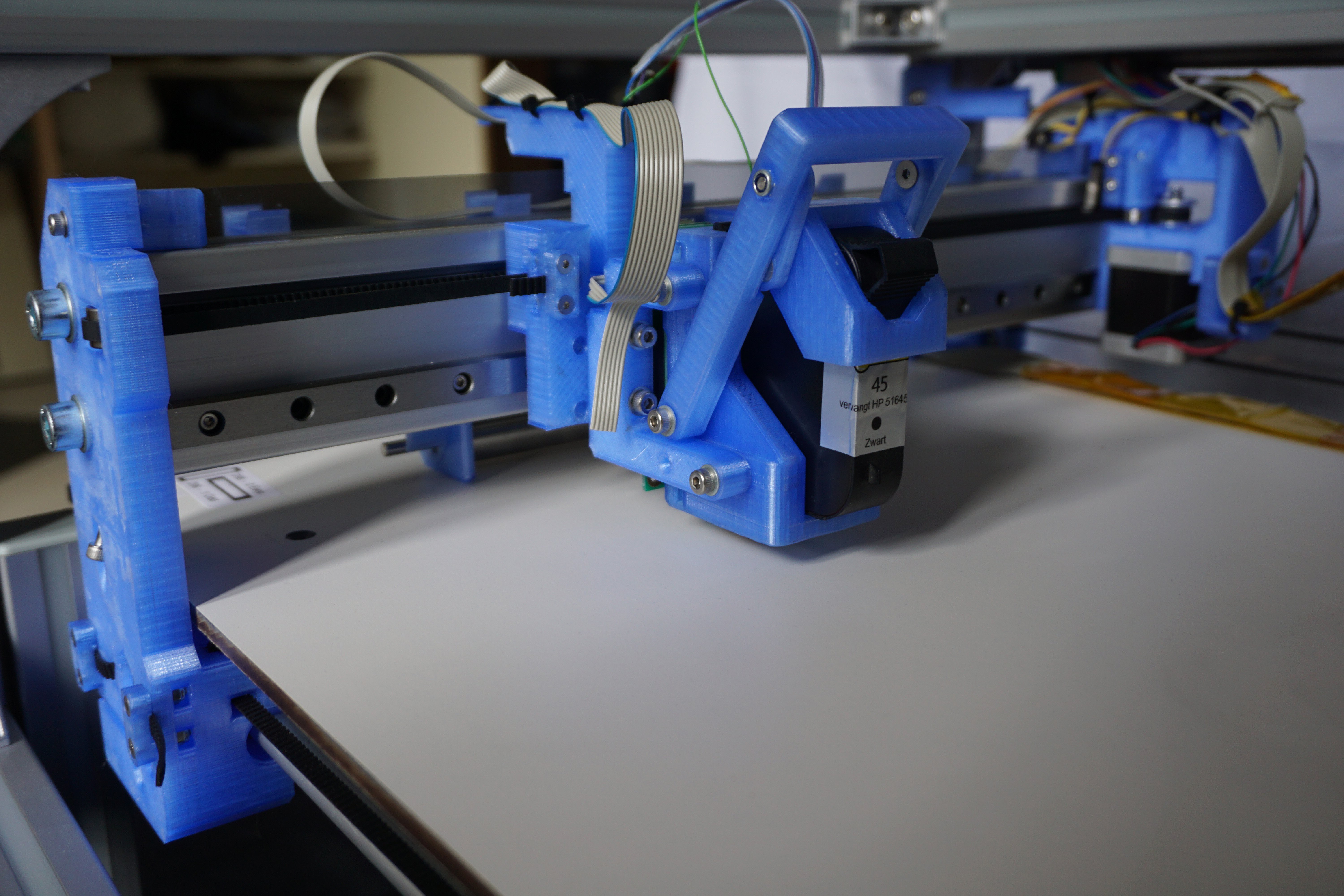

Carriage

The carriage holds the HP45 controller, and deserves a bit more attention on its own. It is a part that should be very usable on it's own. I will order more components and make an assembly guide for the whole printhead on it's own with another set of parts. Can't promise when, it might take a few weeks, but I will. Remind me if I forget.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.