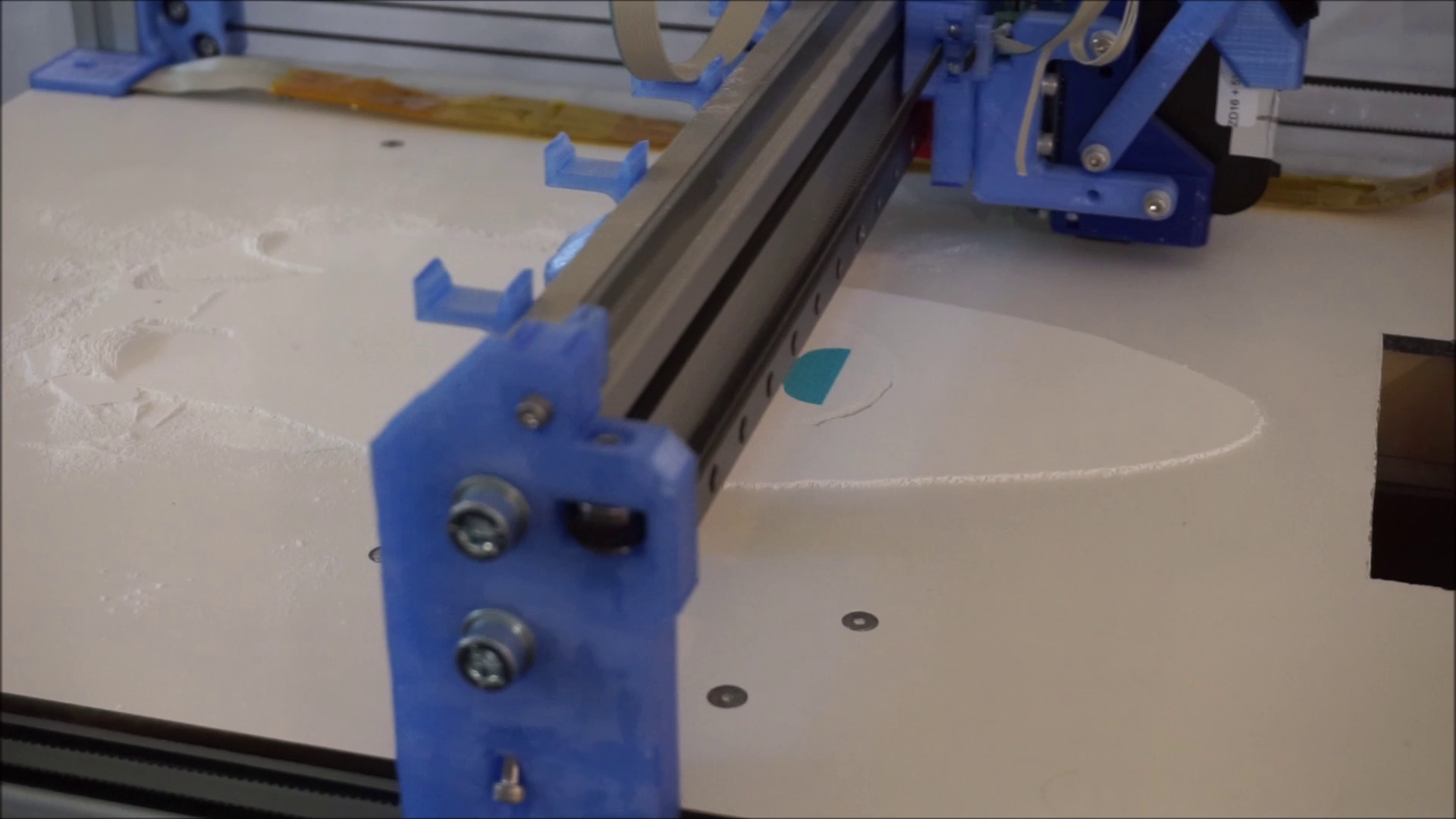

One of the biggest annoyances of Oasis for me has been the spreader. It does an amazing job spreading a new layer, but it has one quite big flaw. It drags powder back.

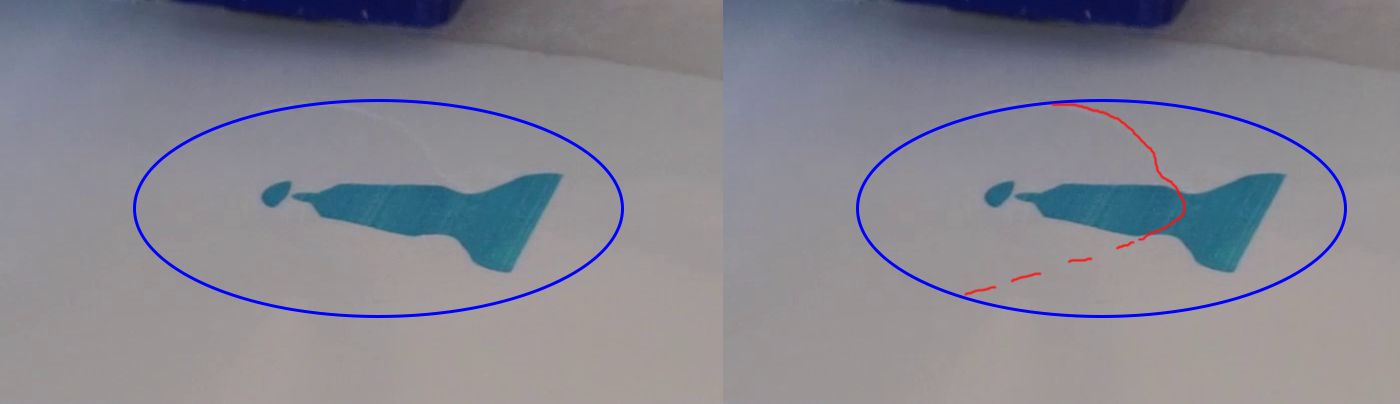

This dragging back the powder should not be happening. The pistons lower to move out of the way of the spreader. However, there is quite a bit of overshoot after the piston, and there is powder on either side of the piston as well. This is the powder that is being moved when the gantry moves back.

The first reason I know it does is because I can see powder being moved when the spreader moves back, the second reason is because there is powder behind the spreader and this heap of powder gets bigger every new layer. The third reason is that in the build piston there is an edge of powder that is moved from the overshoot, back into the build piston. The excess powder in the build piston is actually a serious problem that I do not want.

This problem is cause by the spreader not being perfectly concentric, and some slop in the mechanisms. There are plenty of things I can fix here, but I am going to make the spreader lifting.

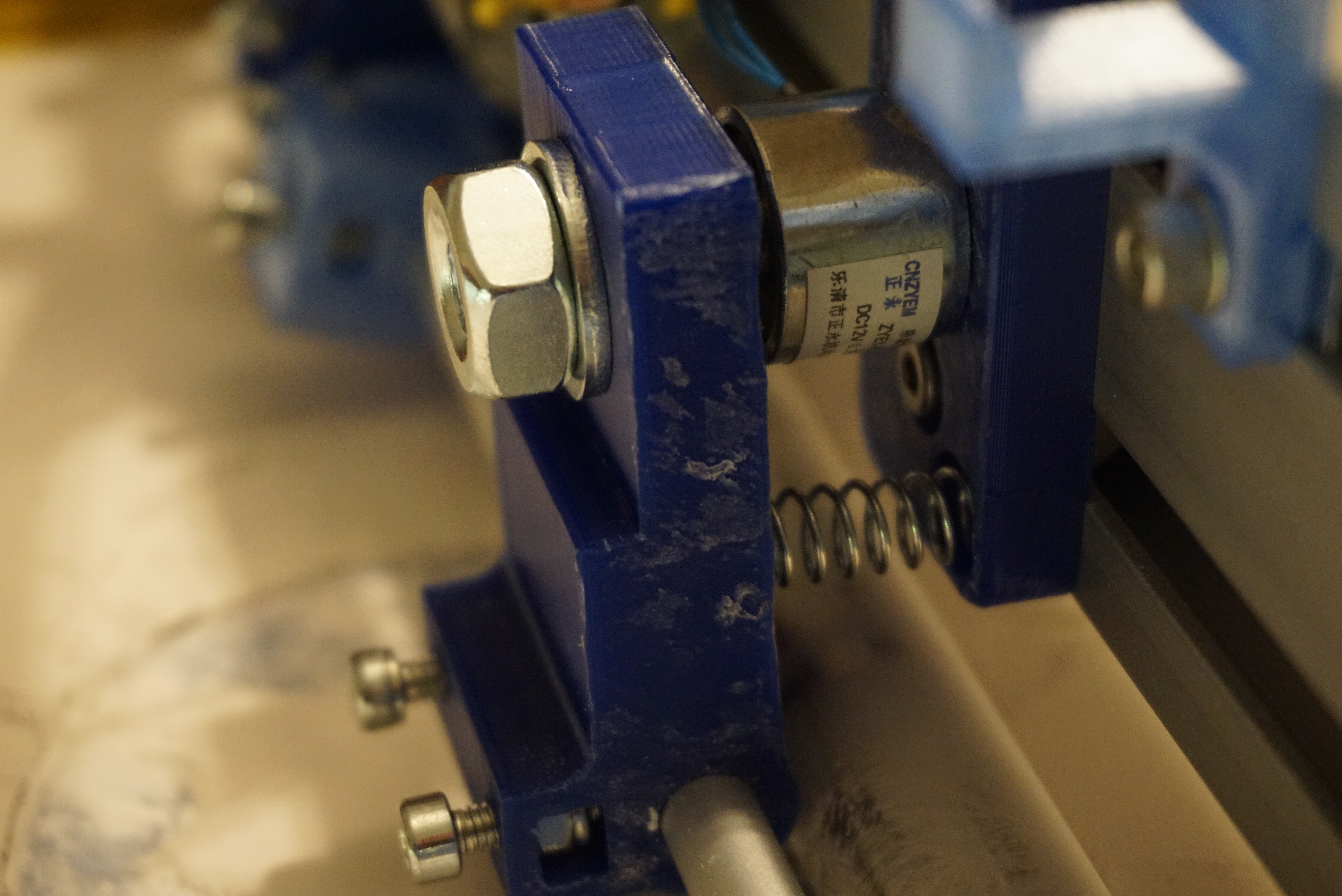

The requirements are simple. When the spreader is on, the roller must be down. When the spreader is off, the roller must be up. The positioning needs to have a high repeat accuracy. It must also not move up under the load of powder.

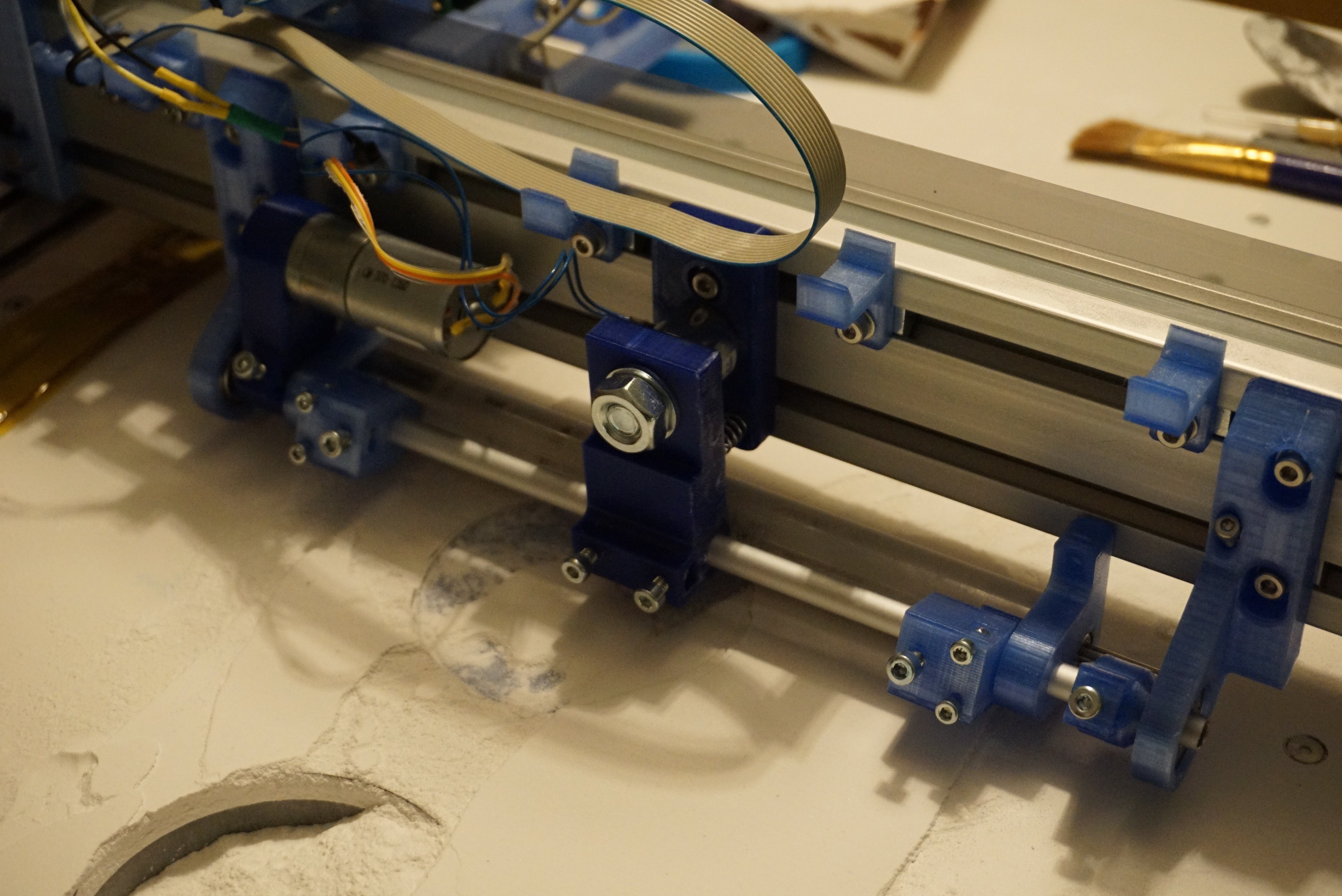

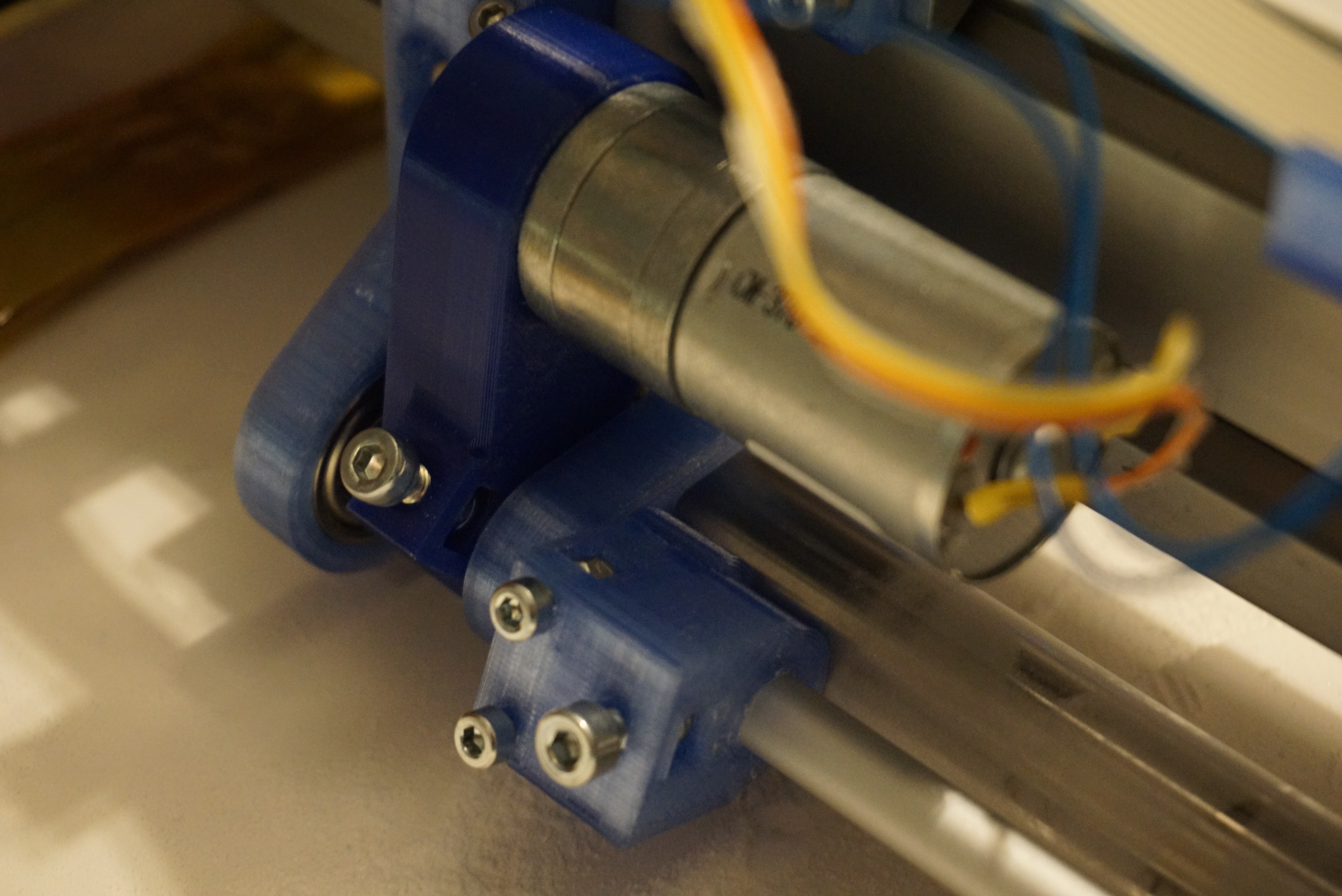

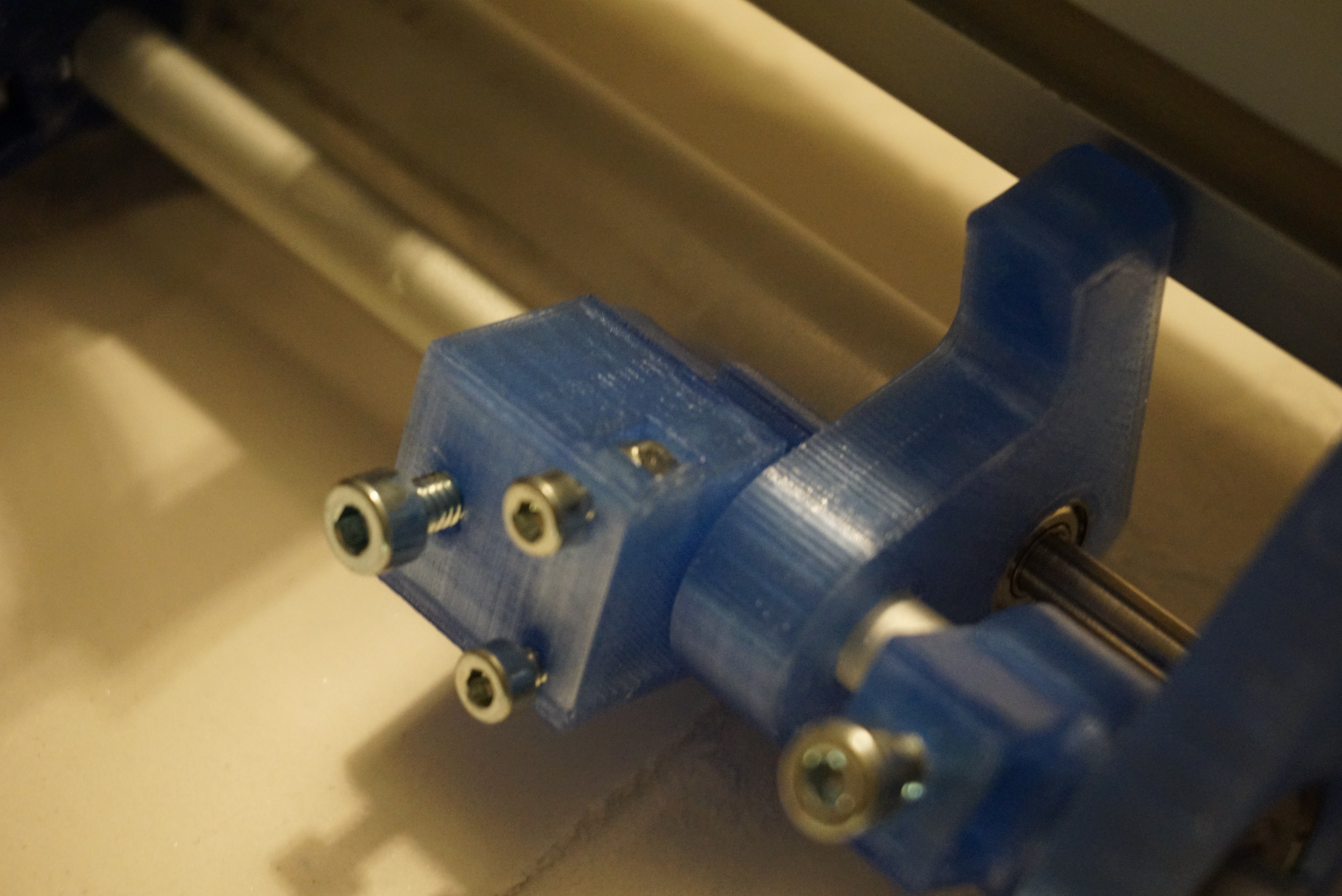

I chose a central shaft in 608 bearings to move the spreader on. This way, the spreader moves in it's entirety, and not only left or right. There are plenty of adjustment options I can make, but the old adjustments turned out to be perfectly adequate.

I run GRBL, so I do not have many options for driving it. Hobby servo's are not an option here, GRBL does not really support them. The only reasonable options that do not require many modifications are solenoids and electromagnets. 12V is one position, 0V is another (with a spring). I chose electromagnets since I had them (Specifically, this one)

In the video you can see the spreader moving down (snapping into the electromagnet) when the roller is powered, and springing back up when the power is removed. The up position is a bit springy, but that is OK.

Because the spreader is now lifting, I will change the software so I can toggle between moving the pistons out of the way or not. For the lifting spreader, I do not need to move the pistons down, saving a second or 2 on every new layer. This software will not be shared instantly, There is more I want to do. The CAD will be uploaded shortly.

The old spreader works fine for the people who are building Oasis right now. The new one is just a little better at the cost of complexity.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.