Human shoes are an utter disaster for lions. The single greatest idea for making human shoes fit lion paws came from

http://fellrnr.com/wiki/Modified_Nike_Free

This is the only way we can run reasonable distances without blisters, pantar fasciitis, & black clawnails. Over the years, as lion fitness improved, distances & speeds increased, & even this has run into limitations. Barepaw running is unacceptable, because of the dog manure, human waste, & rocks. Humans are nasty animals.

Another problem which has arisen is shoes are now being discontinued after only 1 production run. Like books, programming languages & blockbuster movies, they're sold more for publicity & thrown away. Finding another shoe which works as well as last year's blockbuster can take years, if ever. The only long term solution is making shoes from scratch, from easily obtainable materials.

After extreme blistering in a 19 hour race, lions experimented with slow quarter miles in $8 Walmart sandals. In the 19 hour race, shoes trapped sand & moisture from the beach track. If they just had more ventilation, the problems might have been avoided. Sandals could actually hit decent speeds, with a bit more upswing. It became clear the best chance lions have of reaching the next level is modified sandals. Sandals won't allow the maximum speeds, but they should allow the maximum distances.

Humans have since created

https://xeroshoes.com/

https://lunasandals.com/

extremely expensive versions of $8 Walmart sandals, with more straps. $40 for the Xeroshoes Genesis would be reasonable if it wasn't for another problem. The last pair of shoes wore down in only 3 months. Most of a lion's life is spent running on inner foam rather than rubber.

The Goog may actually embargo all but adsense paying commercial links, since it reveals no hacks. Of course, lions don't sew & don't want to be like the male humans who do sew.

http://www.diyfootwear.com/huarache-sandals/

A nugget of info escaped the Alphabet corporation's embargo.

https://www.youtube.com/results?search_query=Huarache+Sandals

Sandals & how to tie them. All these guys have pretty beat up feet & watching their videos conjure up foot odors. Something is a bit off when it's only being done by men. The dominant search result is https://www.youtube.com/channel/UCAq7JfGUobKA-pDDxVQ58Rw, but he's bald.

1st lion run in sandals

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Current bill of materials:

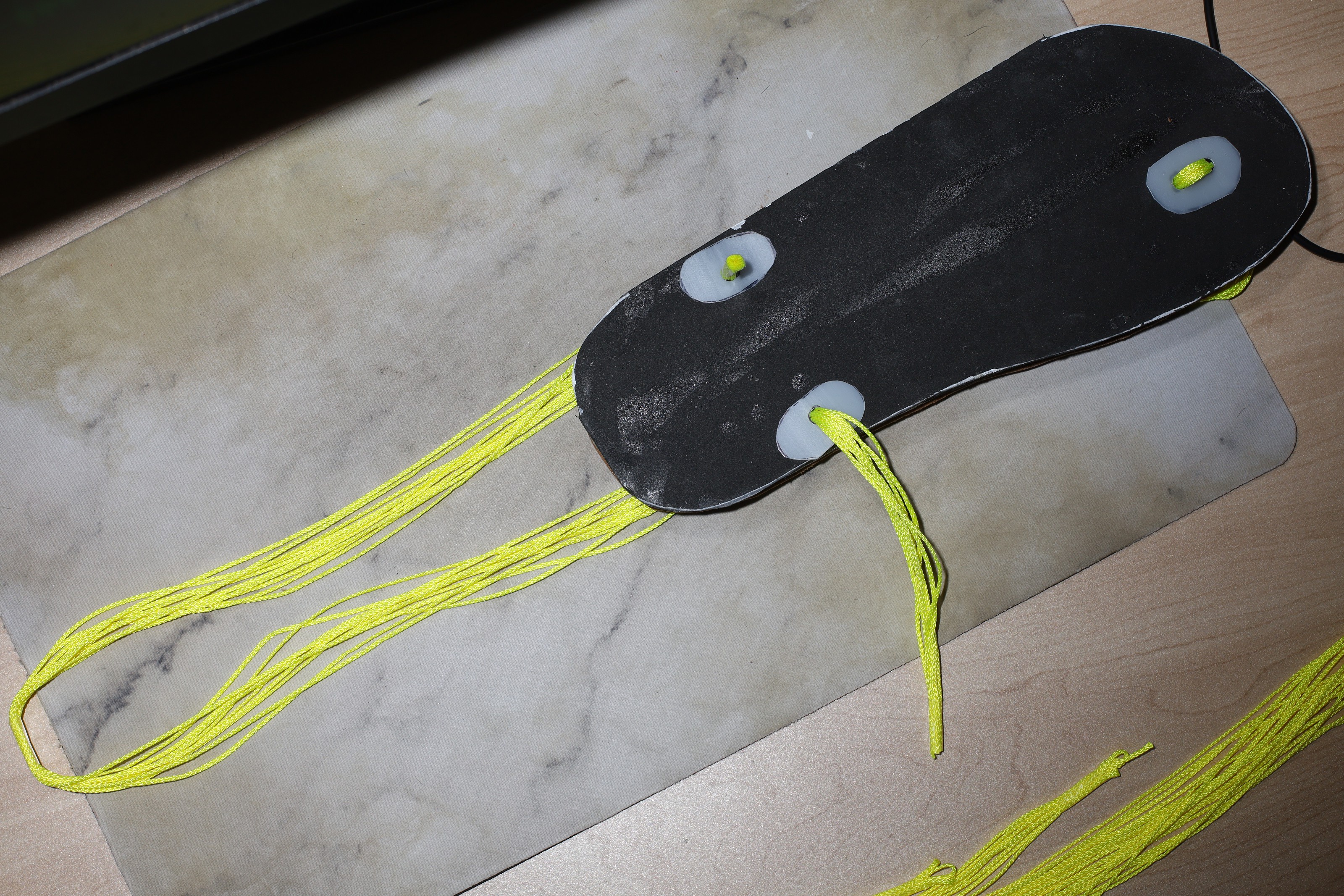

1mm Vibram soling sheet for the bottom, adhered with E6000:

https://www.amazon.com/gp/product/B00FE459NA/

https://www.amazon.com/Vibram-Tania-Protective-Sheet-Style/dp/B00I3LW9K2/

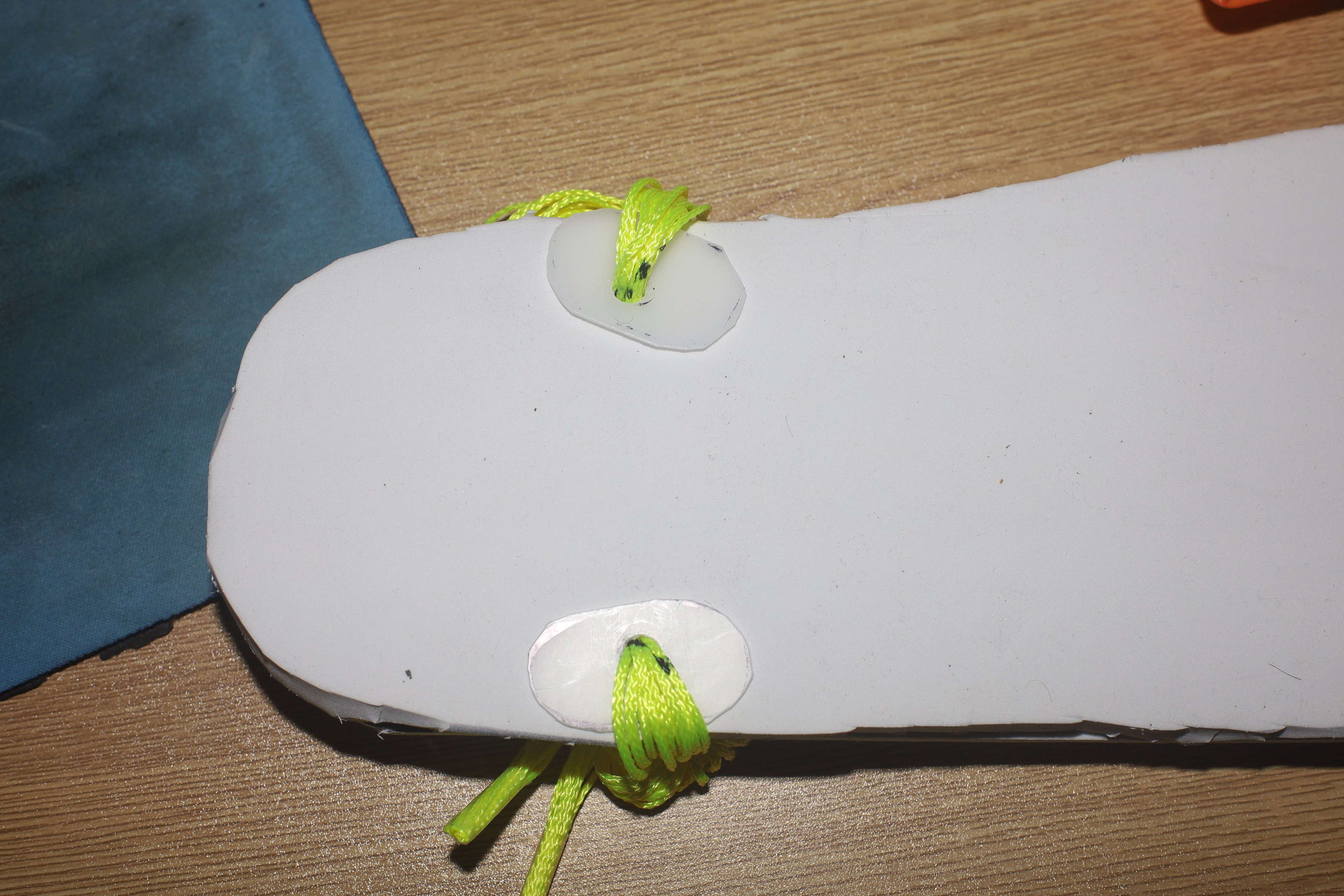

For the top, 2x6mm white EVA layers tacked by E6000

https://www.amazon.com/Bulk-Buy-Darice-1199-20-10-Pack/dp/B0033M2FBY/

or 10mm EVA combined with a 6mm EVA to get 16mm

https://www.amazon.com/gp/product/B082KH2CMJ/

Maybe a top layer of fake leather to improve traction in rain.

#18 yellow nylon mason line for the heel strap & toe strap.

White string is a different material that degrades over time, so yellow has been the only useful string.

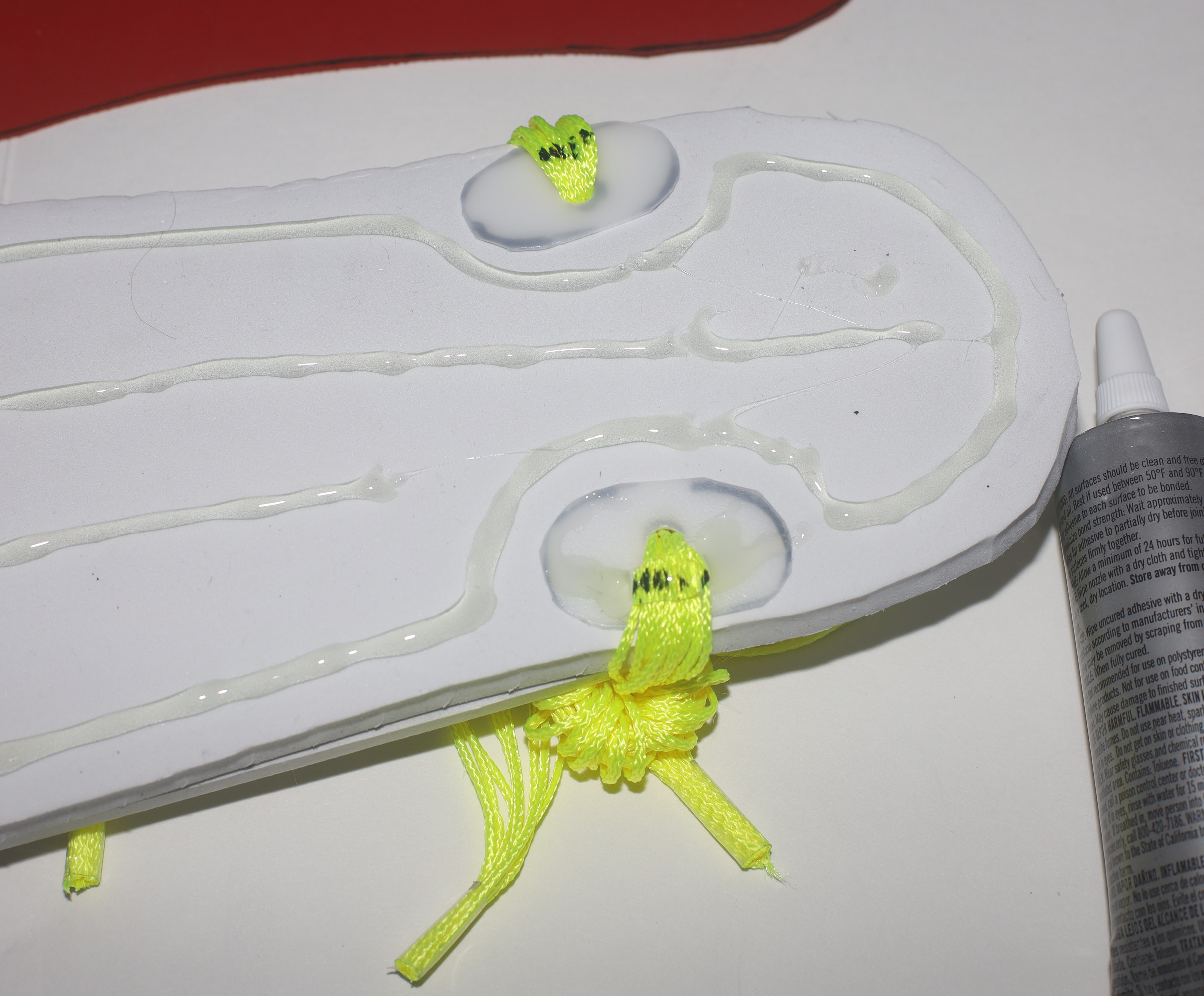

E-6000 adhesive.

Hot glue.

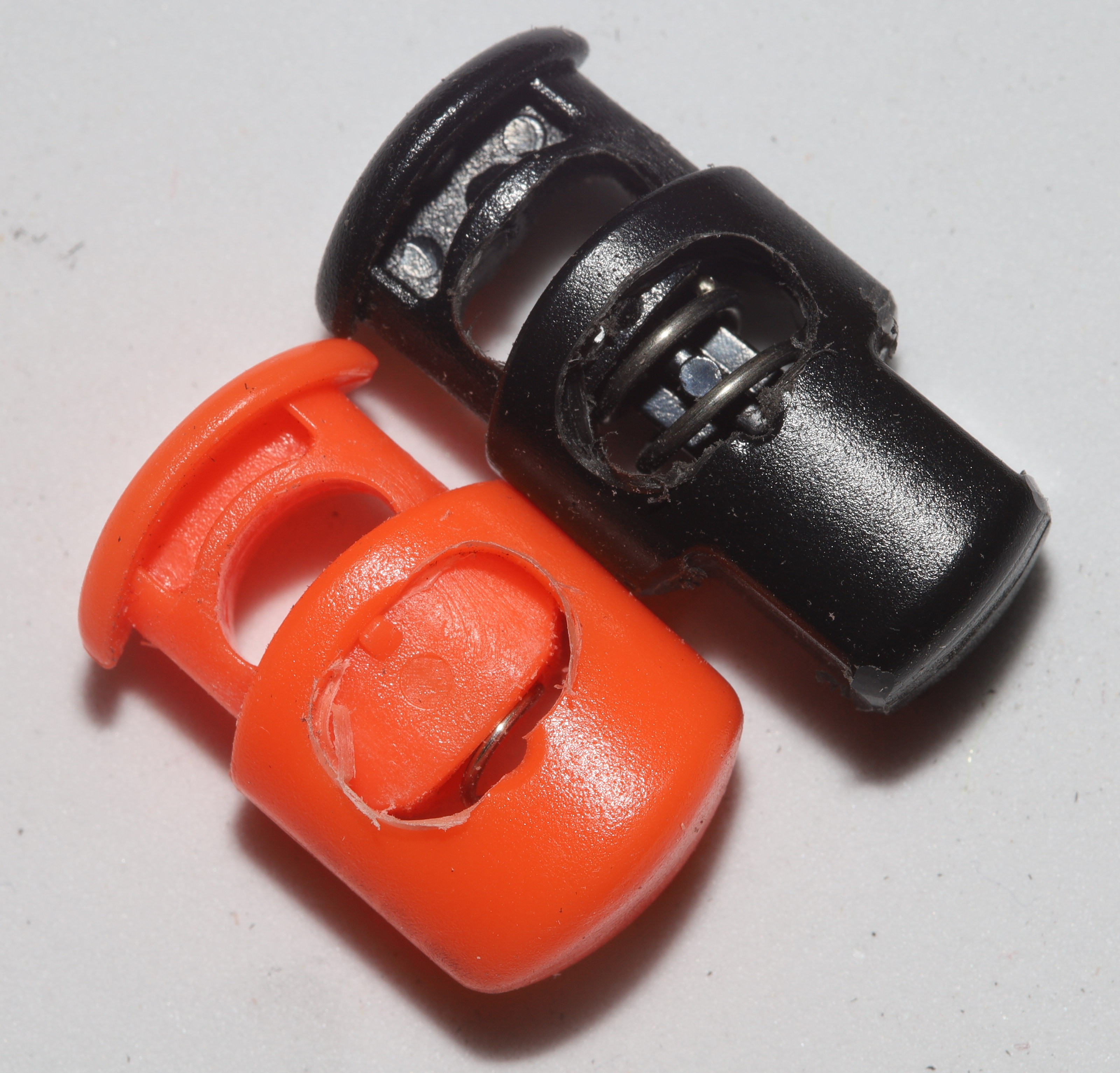

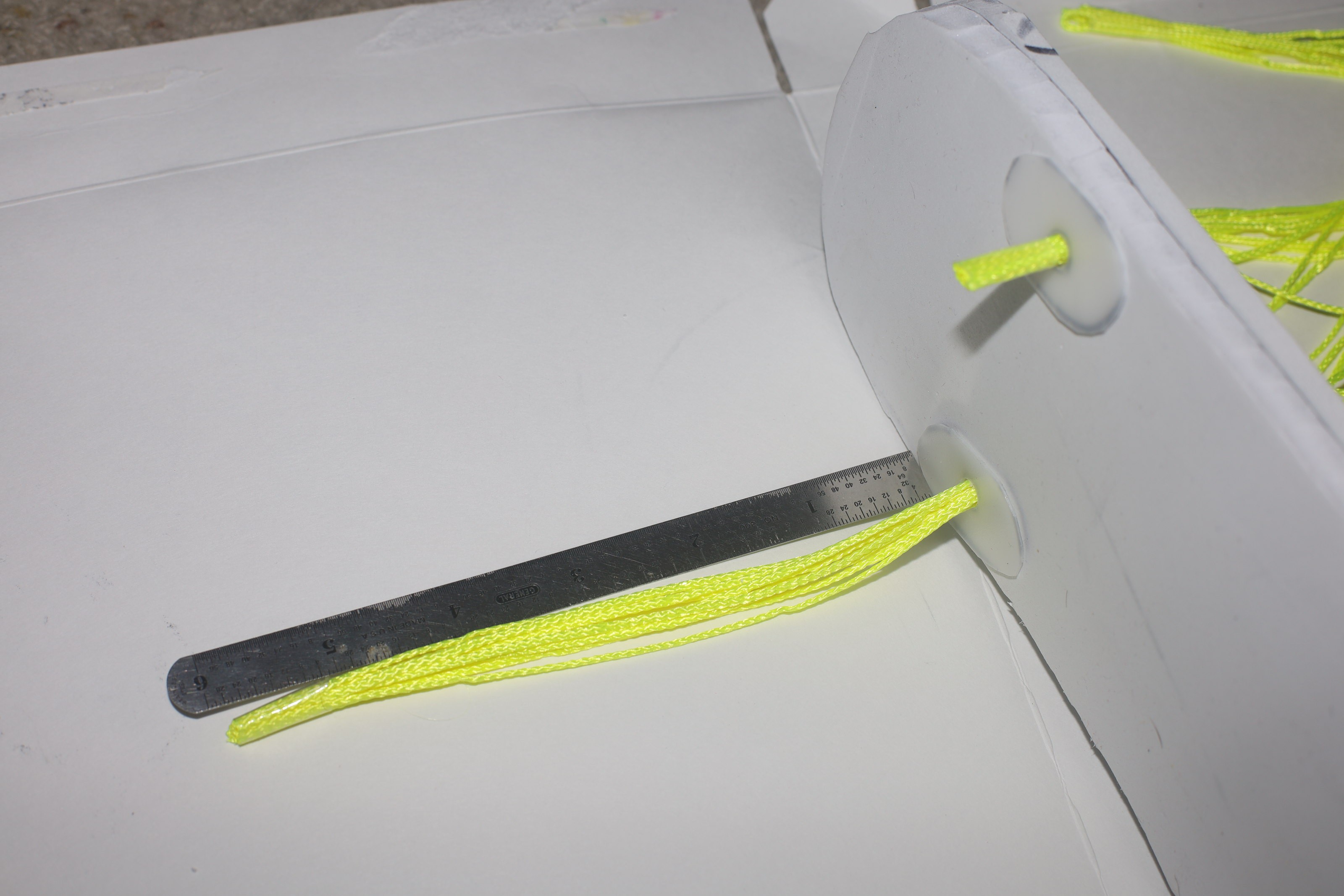

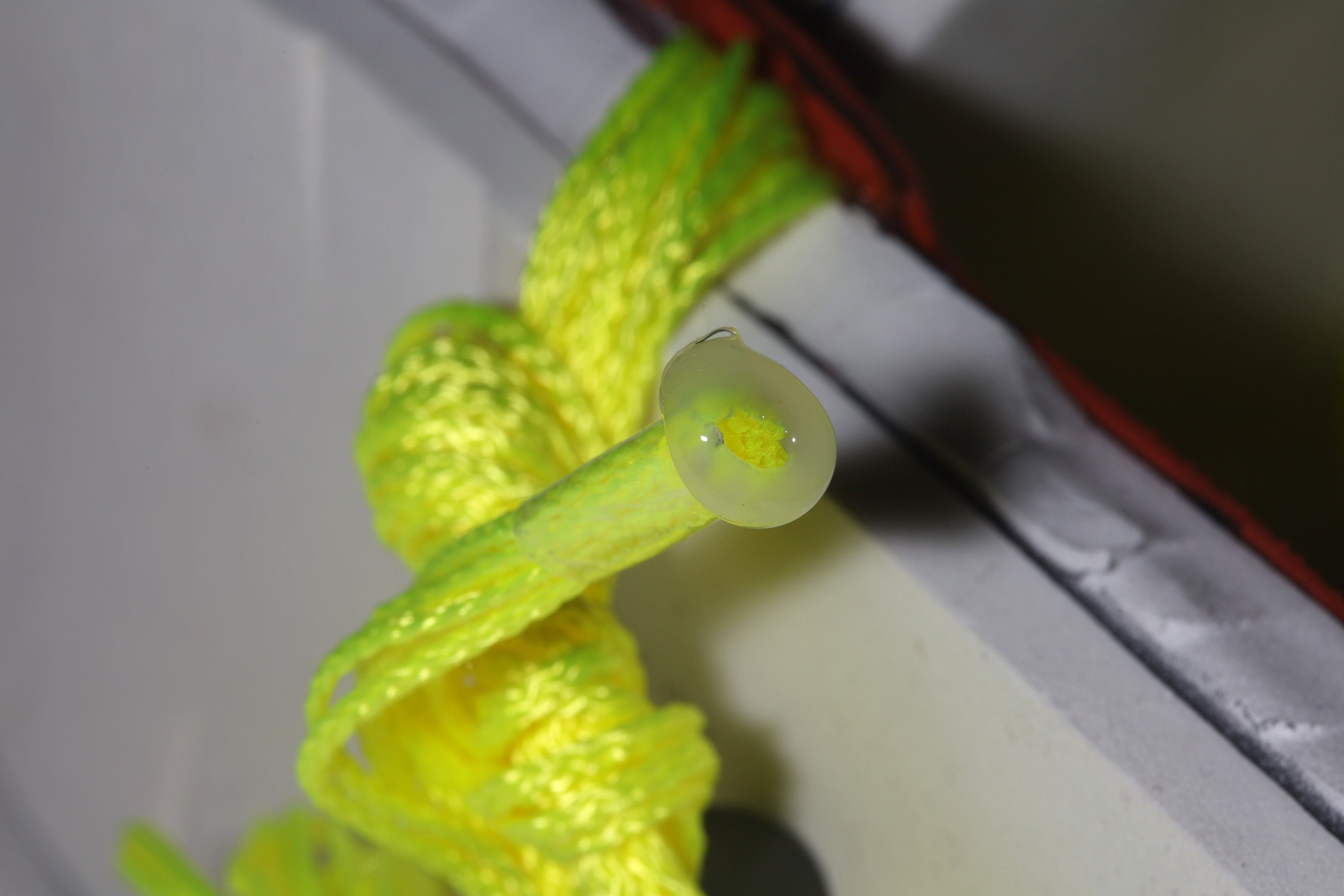

Cord fasteners with 8.25mm or bigger holes.

https://www.amazon.com/Haiker-Plastic-Toggle-Spring-Single/dp/B01JWJ911S

A polypropylene alcohol bottle turns into plastic reinforcement pieces.

-----------------------------------------------------------------------------------------------------

Assembly:

The toe strap uses a bundle of 8 x #18 string, 19" long.

The heel strap uses a bundle of 10 x #18 string, 35" long.

Bundles of parallel strings have proven to be the least abrasive laces.

The ends are taped with scotch tape & then cut after taping.

There are 2 cord farsteners for each sandal. A small orange one farstens the 8 strand thong to the 10 strand heel. The large black one farstens the 10 strand heel to the 10 strand heel. The large fastener has to be ground out to fit the 10 strand + 10 strand laces, but the small farstener doesn't have to be ground out to fit the 10 strand + 8 strand laces.

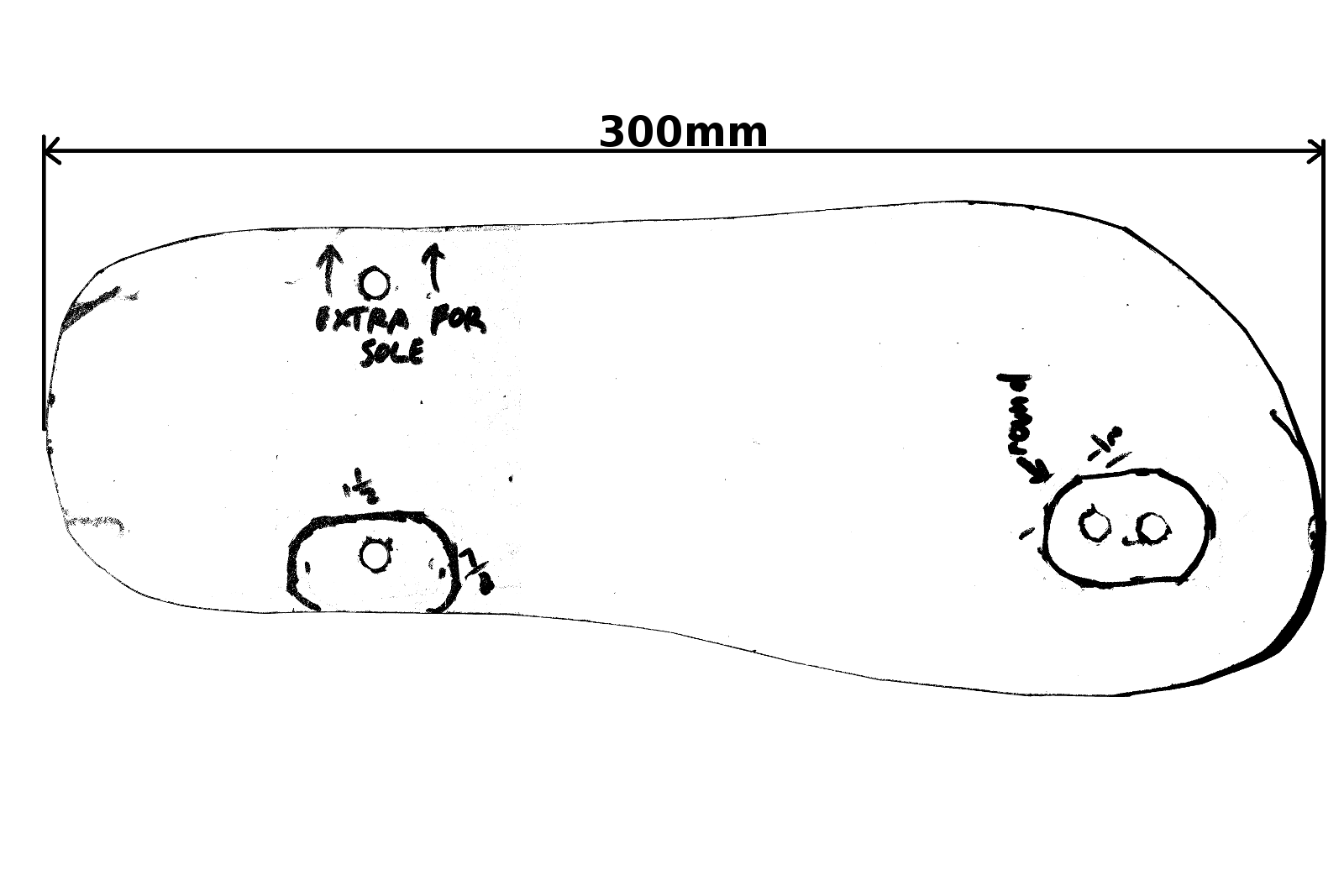

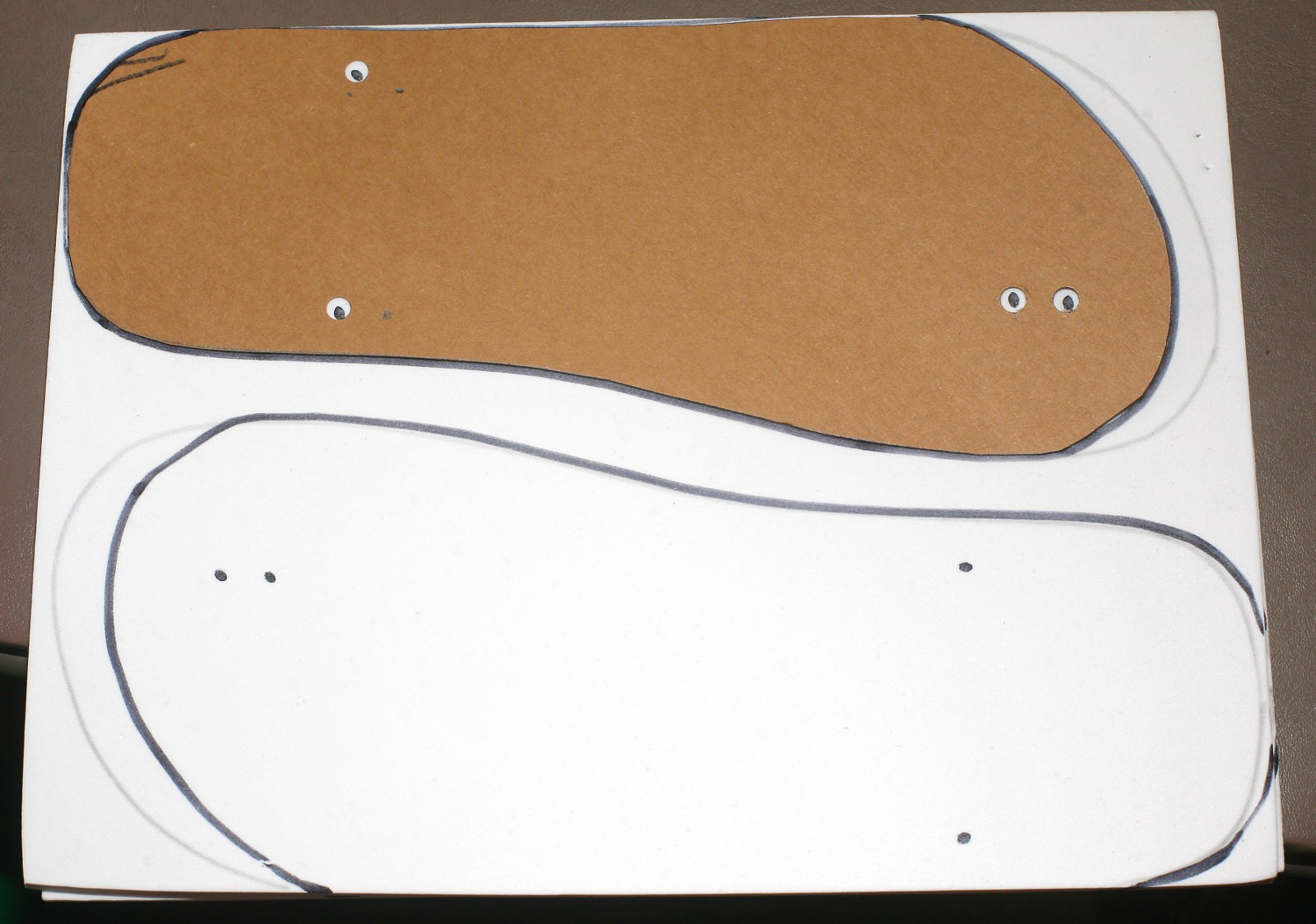

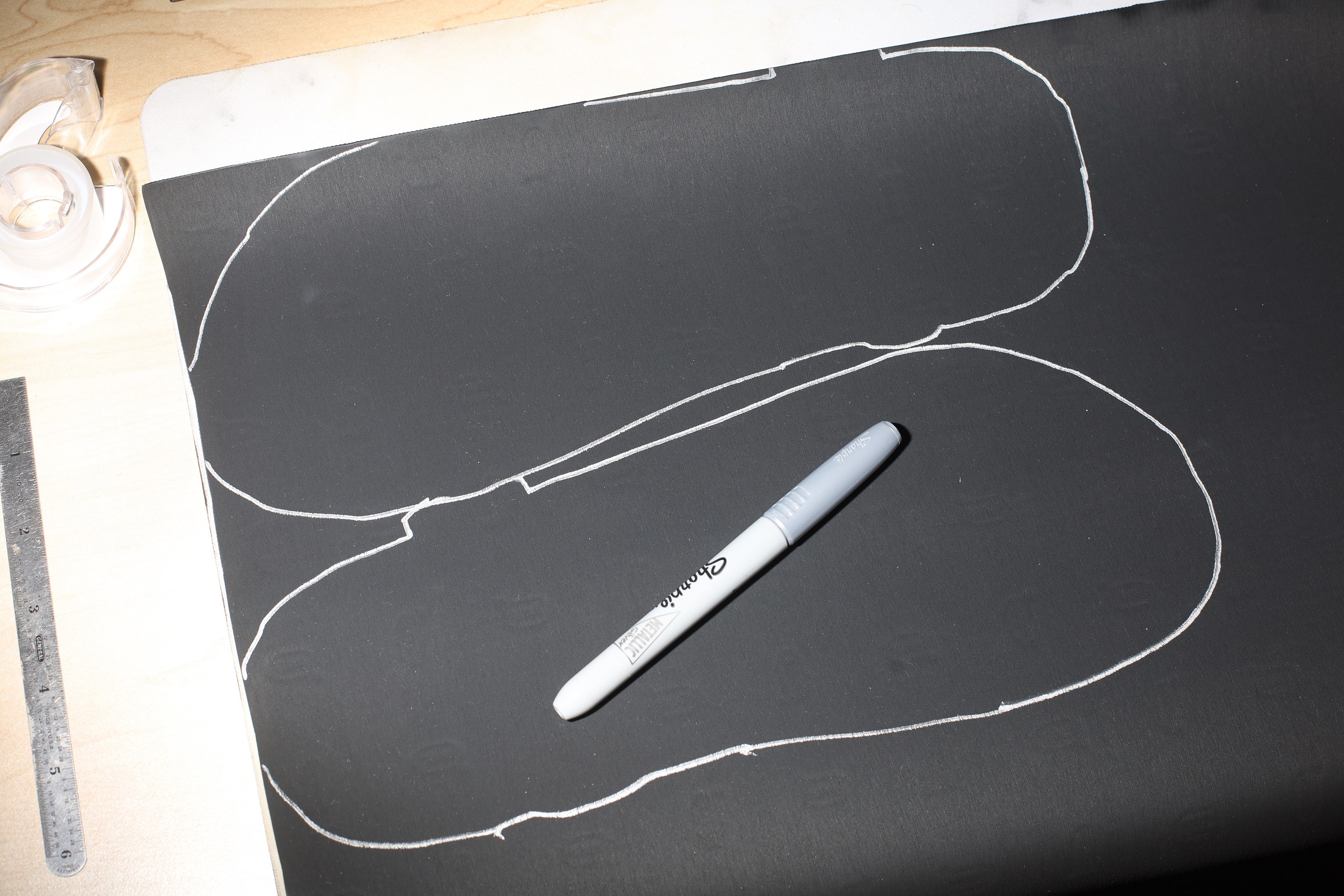

There is a template which when printed to scale provides the dimensions of plastic reinforcement pieces & the sole.

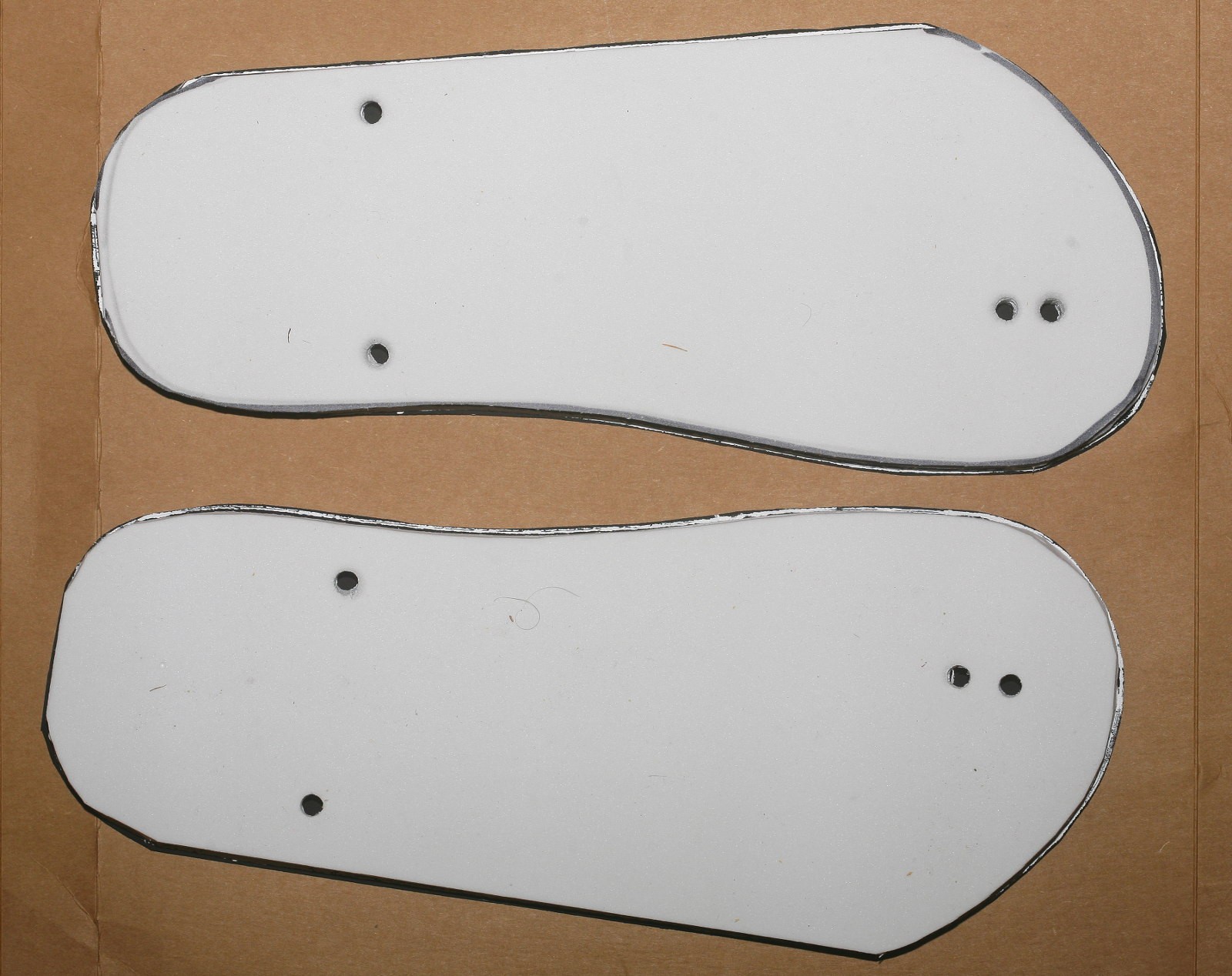

Polypropylene from old alcohol bottles becomes plastic reinforcement pieces.

The plastic is heated, then hole punched when it's soft.

The pattern is drawn on EVA. The EVA is cut with scissors. It can also be cut with a soldering iron or hot wire & lots of ventilation. Sandals have always been made of 2 layers of EVA. For speed, use 2 x 6mm sheets. For immunity to rocks use a 10mm + 6mm sheet.

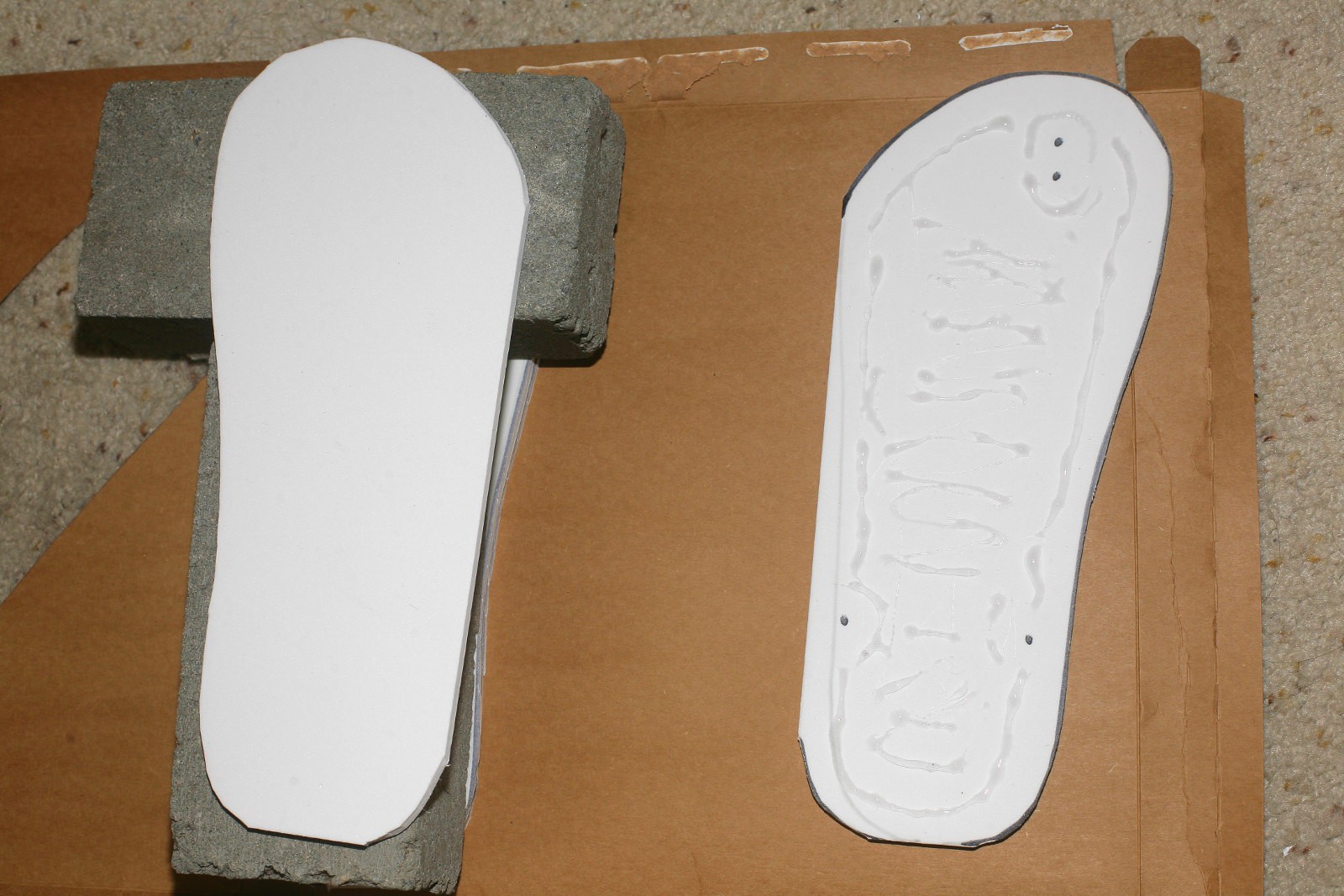

E6000 is applied to 1 layer of EVA & 2 layers are glued together.

2 layers of EVA are clamped around the edges until the glue cures.

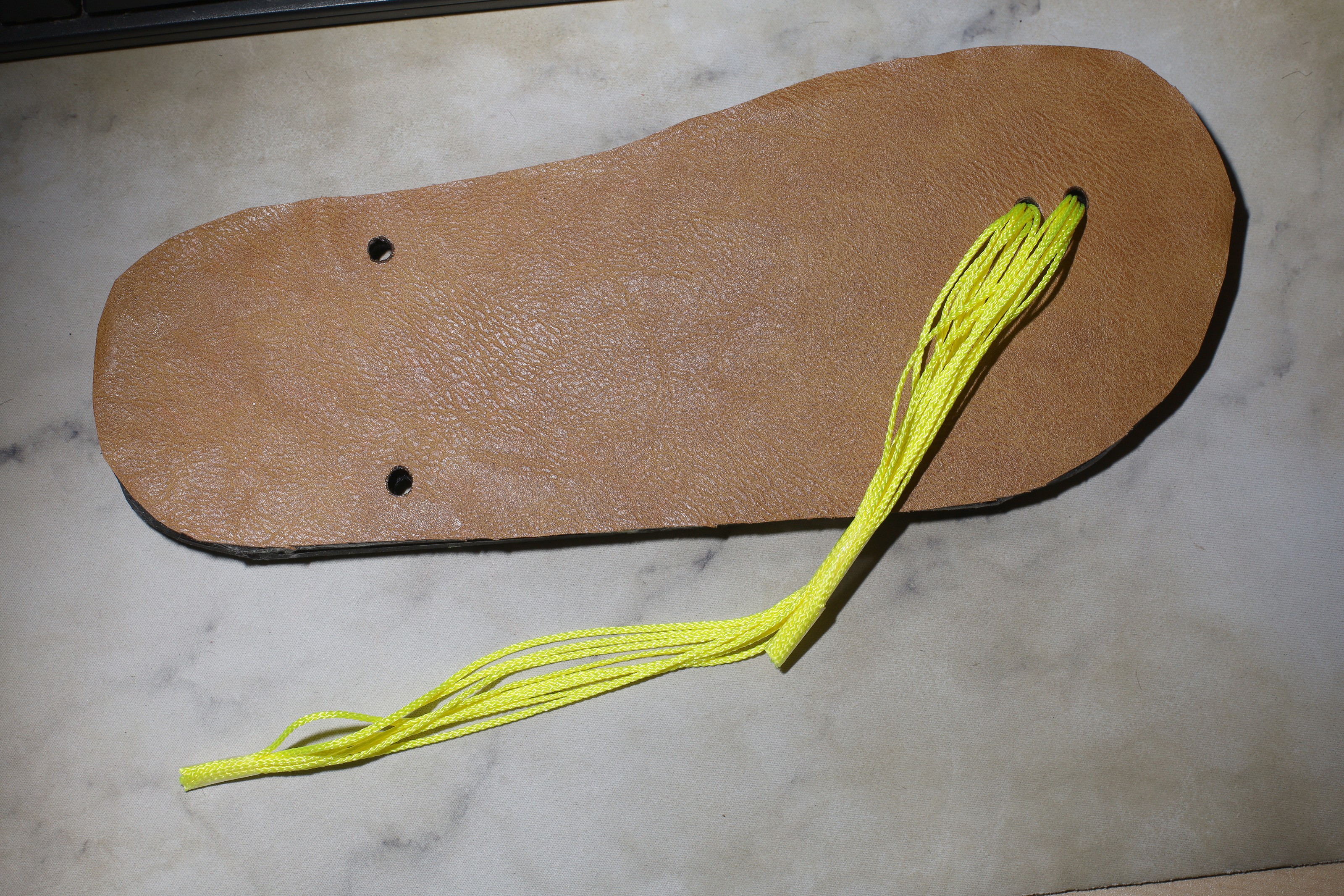

For improved durability, a layer of fake leather is glued on with E6000. This can be weighed down with bricks.

Holes are melted with the full diameter of a T-12 soldering iron. The trick is using lots of ventilation & pulling the tip out without it getting stuck. It's easier to melt partway into both sides.

Soling has to be cut based on the final EVA size rather than the template. It has to be 1/8" wider around the string holes, to prevent sideways expansion of the foam from pressing the string directly on pavement.

String & plastic reinforcers are installed.

For the rear string ends, the piece on the inside of the paw needs to extend 6" & the piece on the outside of the paw needs to extend 1".

The thong is extended based on the size of the paw & scotched into a loop.

The rear string is taped right in the middle of its long loop.

Then the long loop is pulled tight so the tape lands in the middle of the sandal.

Then the tape is pulled back to 1/2" beyond the rear. This determines how far forward or back the paw is going to sit in the sandal. It can be adjusted more, later.

At this point, the string positions in the holes should be marked to keep those constant during fabrication.

The rear string ends are wrapped around 3 times. The inner string is now longer than the outer string, allowing them to be fastened on the outside of the paw.

Fasteners are installed. A small orange farstener will attach to the thong. A large black farstener will attach to the ankle strap. The orange farstener is stock. The black farstener has been ground out for 2 laces to fit inside.

Rear laces fastened.

Thong is installed.

Once all the farsteners are installed, the string ends must be adhered with CA glue to prevent individual strings from slipping out. CA glue must not be applied until the lacing is done, since they won't go through the fasteners anymore.

The laces are tightened against a paw. The trick is keeping the heal lace centered. The farsteners should all be on the outside, where they won't press on any body part.

Finally, E6000 is applied for the sole.

The outer ankle string must be glued. The ankle string is pulled sideways by the thong, so this tries to keep it centered.

The sole is clamped around the edges. 2 more clamps are required than the EVA, in order to bond around the ankle string.

Finally, a bead of hot glue over the string ends prevents chafing.

Excess laces must not be cut off. They should be taped into loops. The laces shrink over time.

During the breaking in phase, lace will be shifted in & out of the inner rear hole to adjust how far forward or backward the paw sits. Excess soling material has to be cut from the inside to prevent it from rubbing on the calves.

Extra soling material will have to be later glued on the bottom, where it experiences the most wear.

lion mclionhead

lion mclionhead