This is still in a very limited state, I haven't even drawn any schematics yet!

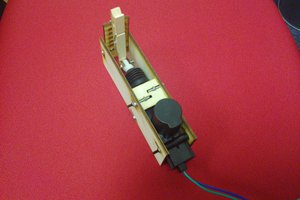

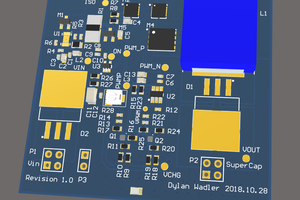

I would like to balance a 3s battery by just connecting a little board to its balance connector.

A low power microcontroller (probably msp430) will be used to switch the capacitors and provide some feedback of when the balancing is done. A hibernation state will prevent overdrawing the battery.

The whole thing could be done in analog, so I might go with that if the component count can stay pretty low.

I expect to use mostly PMOS or PNP to switch between cells because driving NMOS could be tough.

Ross

Ross

sky-guided

sky-guided

adria.junyent-ferre

adria.junyent-ferre

Simon Merrett

Simon Merrett

Dylan

Dylan

Take a look https://www.google.com.br/url?sa=t&rct=j&q=&esrc=s&source=web&cd=2&cad=rja&uact=8&ved=0ahUKEwjtwfvj8YPMAhWBlJAKHYFACq8QFgghMAE&url=http://www.mdpi.com/1996-1073/6/4/2149/pdf&usg=AFQjCNE2Wjw6XdXAaQc3HYQyUuDgXqEpJg&sig2=iuEHd9Xul2pp0Y1i4PLSsA.....