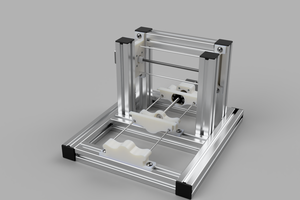

The real key to this platform will be the tool fixture adapter mounted to the tool fixture itself and the carriage mounted to the X axis gantry (left to right direction). It will have one connector for the control sensors and drivers. One AC and or DC power connector, which ever is needed. A pair of headers that will indicate to the controller what type of tool fixture is mounted on the platform. If I use a 232 connector, I have lots of these, I can just use one pin as the common (Pin 9) I have 8 other pins to identify up to 255 (zero would not count in this case) other tools, so maybe use some 4 pin molex connectors from the shack, that gives me up to 7 different tools. The control headers between the tool itself and the platform main controller will be used based on the tool itself, probably just use a pair of 10/16 pin headers. Maybe it will be beneficial to use specific pins for specific sensors and or controls. A drill and a plastic extruder will both have a sensor to detect rpms and will also need to control rpms.

cyplesma

cyplesma

Myles Eftos

Myles Eftos

Greg Duckworth

Greg Duckworth

Ted

Ted

Alastair Young

Alastair Young