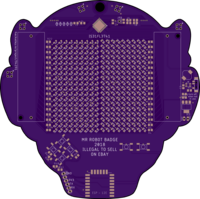

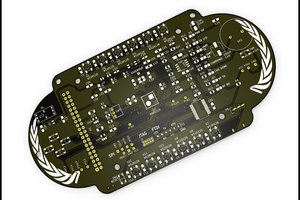

This is what you've all been waiting for. The next iteration of the MrRobotBadge. It's a hardware demoscene with chips you couldn't get a few months ago, the latest in circuit board art, and a massive amount of blinky.

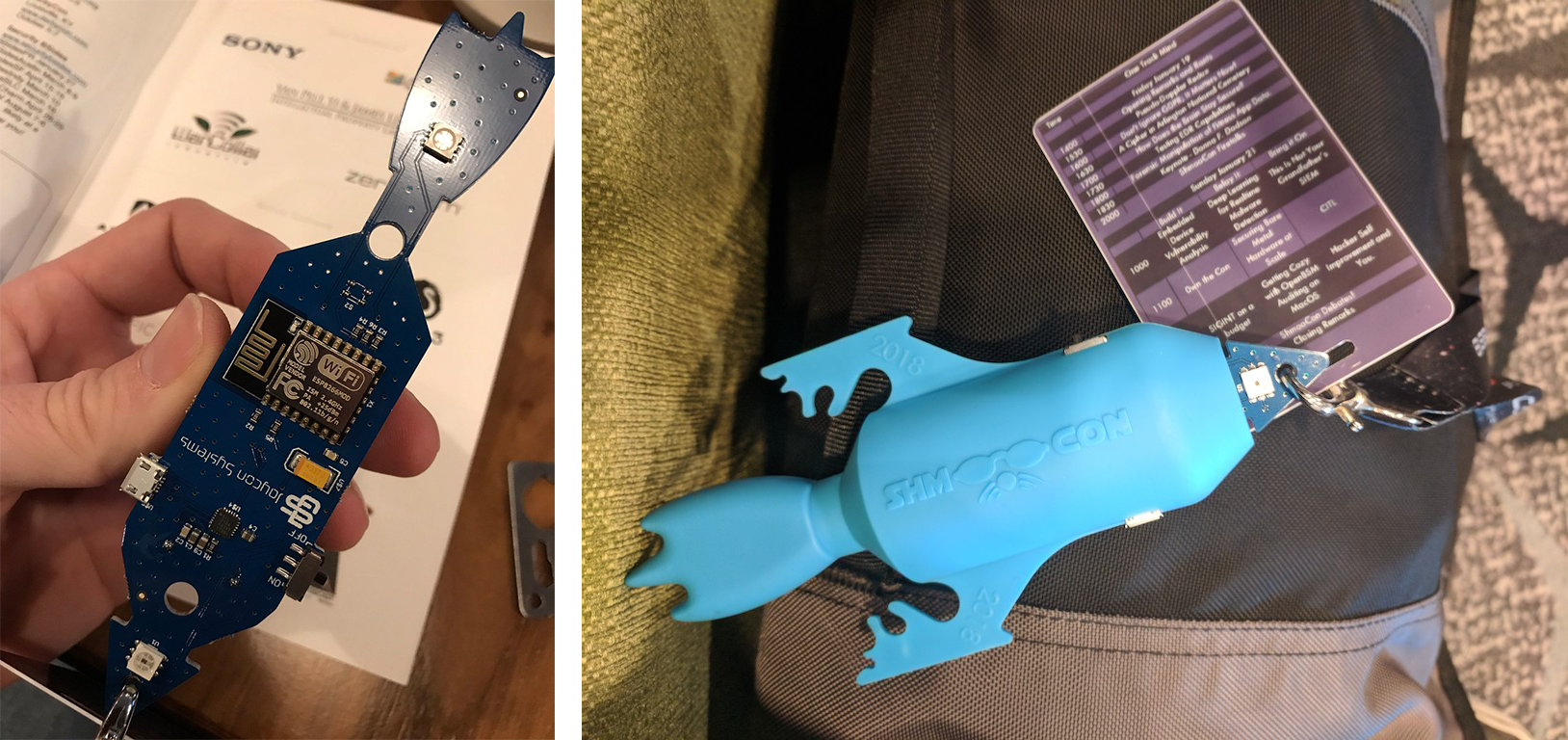

What is the MrRobotBadge? Last year, it was my experiment in gonzo trade journalism. The first iteration of the MrRobotBadge was a project to document the hardware demoscene of #badgelife. This is a community dedicated to creating amazing custom hardware in the form of electronic conference badges. Think of it as a group of people writing software demos for an Amiga, only instead we're using solder, custom ICs, and an incredible amount of manufacturing know-how.

There are dozens of badges being produced by the #badgelife community this year, but I think this one is special. Why?

- We're using a chip you couldn't get in April. The LED driver for the MrRobotBadge Mk2 is a custom implementation of a LED driver designed for RGB backlit mechanical keyboards. We're not doing RGB, but we are bringing a massive amount of blinky to the community

- The greatest in PCB art. The art for the first version of the MrRobotBadge featured multi-color silkscreen, but this year we're kicking it up several notches. We're making tide pods.

- The software! With a gigantic LED matrix, we have a lot of options on what we can do for user interaction. The top of the list: we're going to make blinky fun.

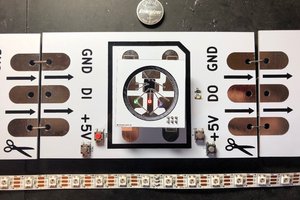

- Shitty add-ons! This year, the #badgelife community has come up with an open standard for add-on PCBs. These blinky baubles work across all badges supporting the shitty add-on standard.

- Better QC, better process control, and a better assembly line. This really isn't going to show in the final badge, but we learned a lot last year and we're putting that knowledge to good use.

So, do you want a MrRobotBadge? Good! We're going to be distributing these at Defcon in August (and possibly HOPE a few weeks before). Check out the project logs below to read about how we created this badge.

Benchoff

Benchoff

blinkingthing

blinkingthing

John Adams

John Adams

awkward intelligence

awkward intelligence